- Posts: 224

- Thank you received: 0

ACMOC Membership Benefits

- FREE quarterly magazine filled with content about antique Caterpillar machines

- FREE classified listings

- ACMOC store discounts and specials

- Full Bulletin Board Access

- Marketplace (For Sale/Wanted)

- Technical Library

- Post attachments

$44 /year ELECTRONIC

$60 /year USA

$77 /year International

(pictures) farming with steel tracks

- North Idaho Farmer

-

Topic Author

Topic Author

- Offline

- Elite Boarder

- User

Those are Jim's aka redpainter's pics of the 4 ways IHs im guessing from over in the Uniontown area?

Always thought the 4 way leveling was cool but in later years it was not that popular here, JD 95-H and 6602 machines had the market, gleaner was fairly common as well. The 70s vintage IH combines were nearly all used up and parked by the mid 90s while the 6602s are still cutting in fair numbers to this day.

Please Log in or Create an account to join the conversation.

Also I wanted to have someone point out the difference (but nobody took me up on it) between the Swing Frame machines and the newer ones that have the leveling device installed somewhere in the Palouse. (Actually the old swing frame I think was developed by Dave Neil in Garfield.

With the swing frame the wheels were kept vertical and ran toward a center in the hill. This made the machines quite stable(Well as much as was possible on slick straw).

The newer machines with the leveling devices locally made merely tip the axle frame. They do not level as far as the swing frame but it becomes less important with rotary machines. Stability is compensated for by an additional set of wheels.

9U(2), 5J, IHC544, Ford860

Please Log in or Create an account to join the conversation.

Always thought the 4 way leveling was cool but in later year it was not that popular here, JD 95-H and 6602 machines had the market, gleaner was fairly common as well. The 70s vintage IH combines were nearly all used up and parked by the mid 90s while the 6602s are still cutting in fair numbers to this day.

Seems like in Columbia and Walla Countys green has been replaced by Red. (Not scientific but observation). We used to call anything from International "Corn Binder" or "Binder" for short and it was never meant to be a pejoraitive term.

9U(2), 5J, IHC544, Ford860

Please Log in or Create an account to join the conversation.

- North Idaho Farmer

-

Topic Author

Topic Author

- Offline

- Elite Boarder

- User

- Posts: 224

- Thank you received: 0

I know JDs are not perfect but these older ones sure are reliable machines, being able to put 200 hours during harvest on a 30 year old combine without ever having to even make a parts run to town just indicates a good product to me. A few gleaner R series are around and they do have the ability because of the transverse rotor and accelerator rolls to cut hills without a leveler but dang a close friend and neighbor puts his R60 and MH2 through the shop every winter like we do and he is always stopped during harvest for breakdowns.

cojhl2- I actually meant to mention that in a previous post but I forgot. Yes hillco makes all the newer style levelers for CaseIH machines as well as the majority of the ones on the JD machines made from the year 2000 and on. The pics from 98J of the 8010 and the 9760 show that new style. Hillco is based out of Nezperce Idaho down on the camas prairie only 30 miles or so south of here.

As for me, I plan on sticking with the old "hillbilly" (actually never heard that term used like that before) combines for awhile

Please Log in or Create an account to join the conversation.

- North Idaho Farmer

-

Topic Author

Topic Author

- Offline

- Elite Boarder

- User

- Posts: 224

- Thank you received: 0

Seems like in Columbia and Walla Countys green has been replaced by Red. (Not scientific but observation). We used to call anything from International "Corn Binder" or "Binder" for short and it was never meant to be a pejoraitive term.

From what 98J has said it seems that his area switched mainly to red as well.

There are plenty of red machines running here, just no 4-ways but a fair amount of 1470, 1670, and then some hillco machines mostly 2388s but a few oddball ones like a 1688 and then the brand new models that I am not familiar with.

I think one reason green combines continued to be popular here and into the eastern palouse right on through the 6622s and up is because of the legumes grown, they are easier to harvest with a walker machine and JD drug that concept on for 20 years after red and silver went to rotors. Also the hills lay different around here allowing them to be cut without the 4wd of the IH 1470 that probably became popular in your area as well as 98j's area.

Just my thoughts on that

Interesting how this thread really took off about the time I thought it was dead, keep it up guys.

Please Log in or Create an account to join the conversation.

- Darrol D8H

-

- Offline

- Premium Boarder

- User

- Posts: 102

- Thank you received: 0

Please Log in or Create an account to join the conversation.

98J, I hope you did not take my "Hillbilly" comment wrong. That is what the factory people called these machines. I got that from a friend that worked for many years for the JD combine division. Also the "Hillbilly" machines are not to be confused with the "Sidehill" which I think they still manufacture.

Also I wanted to have someone point out the difference (but nobody took me up on it) between the Swing Frame machines and the newer ones that have the leveling device installed somewhere in the Palouse. (Actually the old swing frame I think was developed by Dave Neil in Garfield.

With the swing frame the wheels were kept vertical and ran toward a center in the hill. This made the machines quite stable(Well as much as was possible on slick straw).

The newer machines with the leveling devices locally made merely tip the axle frame. They do not level as far as the swing frame but it becomes less important with rotary machines. Stability is compensated for by an additional set of wheels.

Well, what I would call a true Hillside combine or a full leveling combine keeps

the wheels vertical at all times. Unfortunately, they are not made any more,

at least in the USA. Still a lot of them (like NIF's 6622's) working out here in the steepest parts of the NW. Here is a shot of a IH 1670......note that the wheels are vertical........

.......and here is a 8010 with the new style leveler in basically the same spot;

note the difference in the wheels:

( look familiar Darrol.....took you to this field

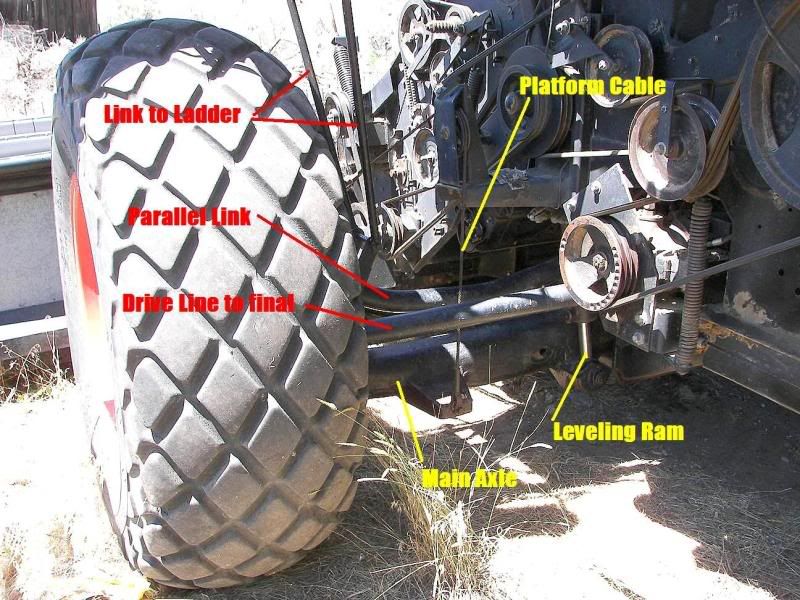

A detail shot of a 1670 with the parts labeled:

The machine is laid over a little here ( we were changing oil) The radius arm

(or 'swing frame' as cojhl2 calls it.....others call it a torque tube) attaches to

the combine frame aft; it serves to keep the final drive, wheel & tire parallel

to the separator body. It is linked to the main axle by the "dogbone" link.

The cylinders that move the main axle up & down are out of sight in this shot.

The platform cable attaches to the main axle as you can see here ( one cable

for each side) .....the other end of the cable attaches to the platform. When

the machine levels, cables move the platform to keep it even with the ground

contour. The platform angle basically mirrors the angle of the main axle. Also

you can see the drive line coming out from the tranny to the final drive.

Another angle.....this allows you to see the leveling cylinder (one on each side) They are tucked in pretty close to the center on a 1670.....on NIF's

6622's they are further outboard.

Another angle. Our ace foreman was fixing a broken leveling pin in this one.

The pin that connects the leveling cylinder to the main axle broke. The cure

is to lay the machine over to the max so you can get at it, drive out the remains of the dead pin, then drive in a new one. As you can see, the drive line telescopes in & out as the wheels move to level the separator.

This type of leveler was used on the JD 95-H, 6602, 6622 (help me here NIF,

the 9632??) and the IH 1470/1670. The rear axle also used a parallel linkage

to keep the steer tires vertical:

This design with the wheels kept vertical gives the absolute best stability;

the tires get a WAY better bite. And before someone asks......diamond treads, not tractor tires are the best in this application.

Please Log in or Create an account to join the conversation.

151, 403 & 453 did not. The Hillside Gleaners, AH,CH, GH & MH2 didn't either.

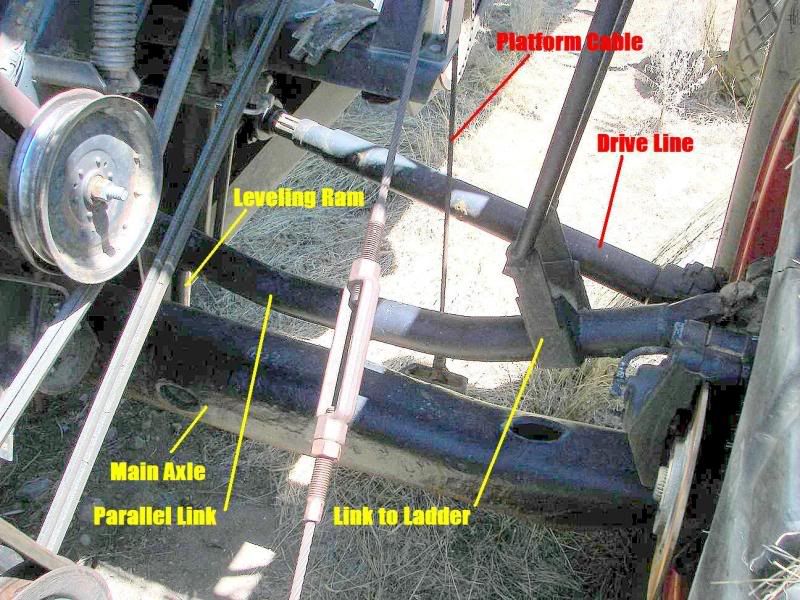

Instead of the radius arm set up outlined above, they used a parallel linkage

both fore & aft to keep the tires vertical. A shot of a MH2....note the lack of

the radius arms .......

A look with the parts labeled. Leveling cylinder attached to the main axle as outlined above.........parallel link on the top side that keeps the wheel vertical.

Telescoping drive line, platform cable and......a fun little wrinkle exclusive to

Gleaners, the link connecting to the access ladder. I'll get to that in a minute.

Looking from the front...one advantage to this set up........no dogbones,

which are a weak link in the system shown above. The turnbuckle in the

platform cable is used to fine tune the platform. If one end is cutting

a little higher than the other, you can adjust that with the turnbuckles (

one per side)

OK, now for the ladder. The access ladder is linked to the parallel link & thereby moves with it. As the left side drive comes up to keep the machine

level, the ladder comes up also.......look closely here;

When the left side driver has to go down.....the ladder goes with it:

A pretty slick set up. It was engineered so that the bottom step was always

a constant height above the ground.

Please Log in or Create an account to join the conversation.

the number of units sold each year dwindled ( hey, there are only so many of

us crazy's to go around) So the manufactures quit building there own. IH built

the 453, but the 1470's were level land 1460's, shipped to Spokane were RAHCO

put the levelers & four wheel drive on. Gleaner stopped building hillside rigs all

together.The last JD full leveling combine was also a mod by RAHCO. To get a leveler now, you either have to deal with the successor to RAHCO ( their name

escapes me) that builds a 35% & a 18% leveler........exclusively for JD I believe.

Or..........you buy one from Hillco that maxes out at 27%. Much simpler and

cheaper to build. A look underneath of an 8010.......lots of iron since it's a Big

ASS machine, but not nearly as complicated as the systems outlined above.

........and they will take you on some pretty nast stuff:

.......son in laws 2388:

........traded it off for a Hillco equipped 9760.....diamonds all the way around:

Please Log in or Create an account to join the conversation.

- North Idaho Farmer

-

Topic Author

Topic Author

- Offline

- Elite Boarder

- User

- Posts: 224

- Thank you received: 0

I notice that all the JD combines are cutting wheat with unloading augers out. Some reason for this, we always retract them so we don't hit a hi line pole or each other. Darrol

Darrol we will fold the unloading augers in when making the first round around the field if there are trees or poles but otherwise it stays out between unloading. Not much point in folding it back and then out again every 15 minutes.

Please Log in or Create an account to join the conversation.

ACMOC

Antique Caterpillar Machinery Owners Club

1115 Madison St NE # 1117

Salem, OR 97301

support@acmoc.org

"I became a member recently because the wealth of knowledge here is priceless."

- Chris R

"I also joined a year ago. had been on here a couple of times as a non-member and found the info very helpful so I got a one year subscription (not very expensive at all) to try it out. I really like all the resources on here so I just got a three year. I think its a very small price for what you can get out of this site."

- Jason N