- Posts: 100

- Thank you received: 3

ACMOC Membership Benefits

- FREE quarterly magazine filled with content about antique Caterpillar machines

- FREE classified listings

- ACMOC store discounts and specials

- Full Bulletin Board Access

- Marketplace (For Sale/Wanted)

- Technical Library

- Post attachments

$44 /year ELECTRONIC

$60 /year USA

$77 /year International

(pictures) farming with steel tracks

NIF intersting modification to the rear of the 6622, what does the flex tube connect to? Auxiliary Fan driven off the walker drive? Where are you directing that air?

Looks like some work ahead of you on the pea header, are you going to fab up some new header pans??

Good stuff guys, thanks again:)

Woody

Please Log in or Create an account to join the conversation.

- Bleedinred

-

- Offline

- Senior Boarder

- User

- Posts: 56

- Thank you received: 0

Please Log in or Create an account to join the conversation.

- Bleedinred

-

- Offline

- Senior Boarder

- User

- Posts: 56

- Thank you received: 0

The Challenger on the farm is the 7th one built, I believe and it works good on this Richardton bankout wagon. It'll go about 14 feet high when we load Jacklin trailers with grass seed.

The 6622s are 1983 models, bought new in '85 and '86 as carryover machines. One just under 6,000 hours, the other around 5,500 and both have original engines, hydros and transmissions. We replaced two finals over the years plus the usual stuff, added horizontal clean grain augers like yours, unloading auger extensions, spray tanks and nozzles behind the headers, etc. The front machine is a 9500 SideHill which only levels 17% so the 22s do the brunt of the hill work.

Please Log in or Create an account to join the conversation.

- Casey Root

-

- Offline

- Platinum Boarder

- Member

- Posts: 331

- Thank you received: 0

Bleedinred, that's the wildest bank-out wagon I've ever seen. That's pretty cool, you just cycle the hydraulics and the thing is unloaded.

NIF and 98J, are there many of the 7722's in your area? As I recall, JD sent incomplete flatland machines to your area and a local installed the leveling system. Was it Hanson? Anyway I'd like to know more about them as none of them ever made it to the central coast of CA. I did notice that the leveling ram on the 7722 is positioned somewhat like the older Gleaners, instead of the big vertical rams like the 02's and 6622's. That system always looked underpowered to me. How well did it serve? Did production on the 7722 start in 1981 or was it later.

I wish I had more photos but I quit farming in 1983, long before digital cameras and the internet. Going to have to do some digging and find some snapshots.

Anyway, thanks for all the great information on this thread.

Casey

Please Log in or Create an account to join the conversation.

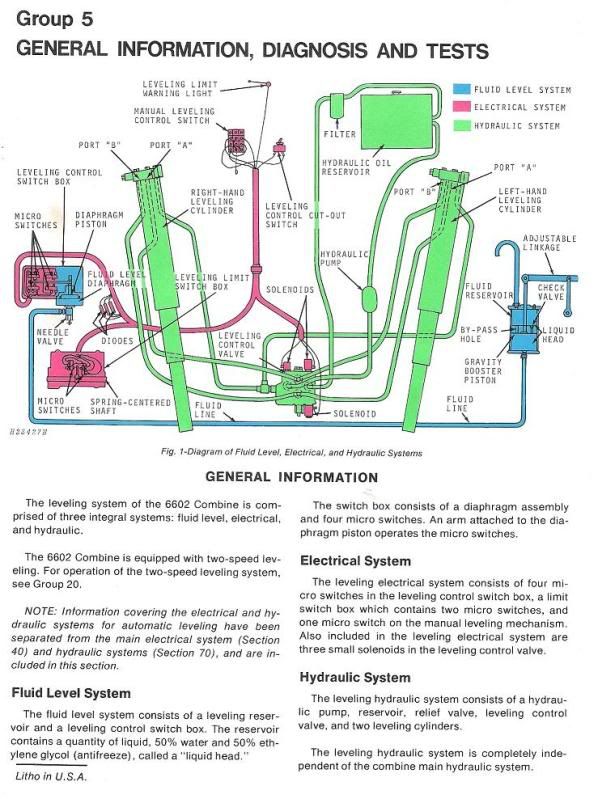

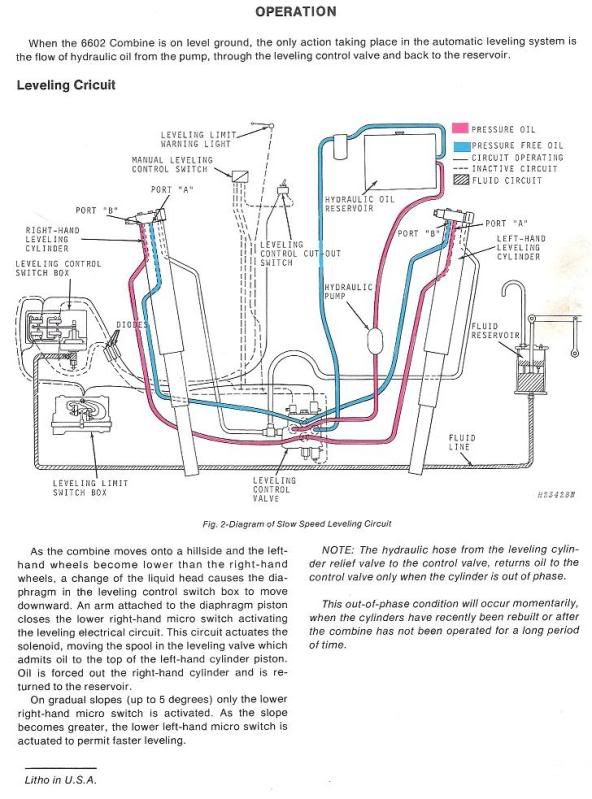

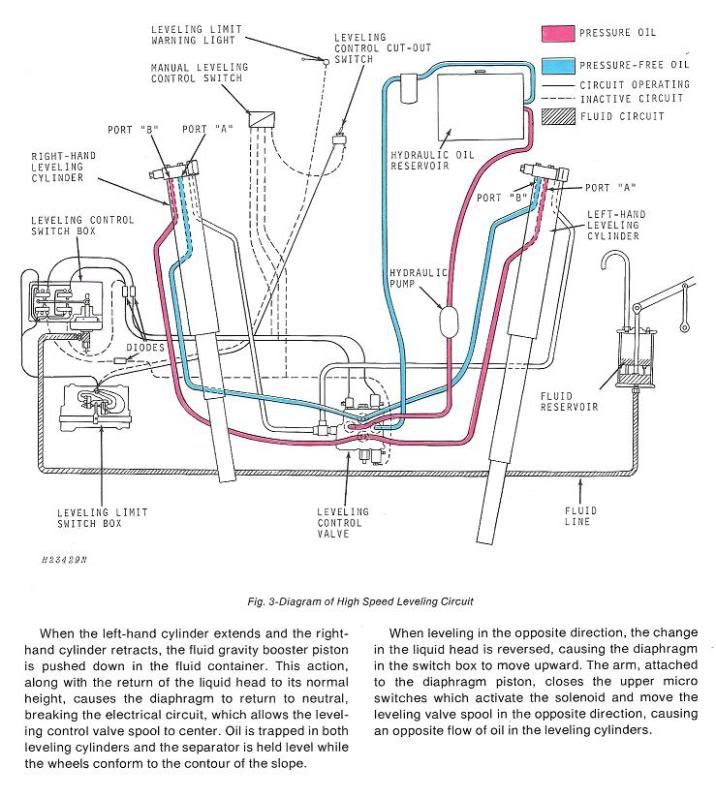

leveling systems are electric over hydraulic....but they don't use a Mercury board to control it. I'll let a JD tech writer explain this time. This is from a 6602service manual, but the same leveling system is used on the 6622 like NIF is running:

I don't see a dollars worth of difference between Fig 2 (above) and Fig 3

(below).......which means the ace JD tech proof reader screwed up. But I threw it in anyway because of the text at the bottom.

PS........to cojhl2......Hillbilly combines indeed!!

screen ( on the radiator intake) FOR YEARS. Nothing......it seems, Burns Like

a Deere:

Please Log in or Create an account to join the conversation.

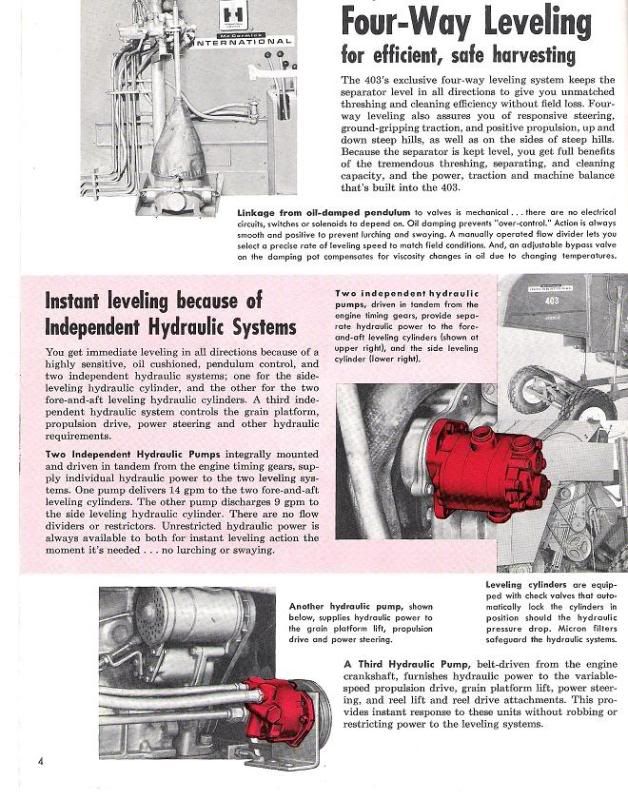

The IH 51 & 160 pull types had self leveling cleaning shoes ( leveled fore & aft) Starting with the IH 151 SP machines, they did away with that, and kept the shoe level by........moving the whole machine. You could have it

either way, two way leveling.....or by adding another set of spools hooked

up to the pendulum......four way leveling:

A good look at the pendulum control;

Uphill in peas.....a pair of cylinders moves the rear axle up & down:

........in peas.......a 403:

.......and down hill, again a 403 in peas

The max level on this series ( 151, 403, 453) is only about 35%, compared

to NIF's 6622's at 45% and the 48% on the 1470/1670 series. An old pull

type like the IH 160 had an eye popping max of 65%. More to come on that............soon.

Please Log in or Create an account to join the conversation.

- North Idaho Farmer

-

Topic Author

Topic Author

- Offline

- Elite Boarder

- User

- Posts: 224

- Thank you received: 0

NIF and 98J great pic's really enjoyed this thread.

NIF intersting modification to the rear of the 6622, what does the flex tube connect to? Auxiliary Fan driven off the walker drive? Where are you directing that air?

Looks like some work ahead of you on the pea header, are you going to fab up some new header pans??

Good stuff guys, thanks again:)

Woody

Yep tube goes to a fan drive hooked in at the chopper, this pic was from the first attempt it 08 which ended up being a disaster, took it off within the first hour of harvest.

In the latest modifictation, the air comes in the back and down and then straight out the sides. This pic is what the set up looked like this past year but it would pile chaff up on the tube which brought the air in from the front and out the sides. Main idea is that the chaff stream comes out and hits the the vertical pieces on the back and falls down into the air stream. Moving into min till and no-till requires the chaff row be spread out. Not many people run chaff spreaders around here as most do all conventional tillage but the few 22s that do have chaff spreaders usually use a mechanical spreader like a turn table or a love spreader. The love style doesnt work well going downhill and the turntables I think would be too dangerous as we like to walk along and take a sample off the stream above the sieves when switching between different crops.

The header project probably isnt as big of deal as it would seem, the pans actually are in good shape they were replaced not too long before it was parked but they werent stainless so they have a bit of rust to remove. Need to redesign the header cart it is sitting on because the angle the header sits changes with a pea bar on, one of our carts wont work at all with a pea bar because of the skid plates beneath it.

Chopping away in a heavy crop of peas, pea bar doing its job perfectly

Please Log in or Create an account to join the conversation.

- North Idaho Farmer

-

Topic Author

Topic Author

- Offline

- Elite Boarder

- User

- Posts: 224

- Thank you received: 0

Not a good picture shot through the window of my machine but if you can see where the uppermost canyon comes into the near one on the left, that is where arrow junction is.

Please Log in or Create an account to join the conversation.

- North Idaho Farmer

-

Topic Author

Topic Author

- Offline

- Elite Boarder

- User

- Posts: 224

- Thank you received: 0

The 9632 combines were the last of the old style leveling....went to 44% and are a very hot item today, they seem to get sold as soon as they hit the lot and go for almost twice the price of what a level land 9600 would be, they run either 25' or 30' headers on them.

If anybody knows different than what I said then speak up but this is what I learned when looking at newer machines.

Please Log in or Create an account to join the conversation.

2nd- With all the terraces in oklahoma i think i would actually be able to justify a hillside kit.

We custom harvested for several years all the way from Vernon Tx. to Winner SD. It was an experience and i prefer to never do it again. Local harvest is more than enough for 1 year.

The neighbors always hired a custom crew with new JD's across from my dads house that didnt do a good job in mine and my dads eyes. We went and saw with a flash light how they were doing after they left when the dew set in early and everywhere they had cut looked as if there had been a hail storm a week earlier. In the uncut part maybe 4 or 5 grains in a 3x3 square.

I dont know about hillside machines but I've run most of the machines that were new about 5 years ago and i'd have to say the R series gleaner crap on about everything ive run (IH, JD, NH). I'd love to go about 12 hours in a challenger with tracks to see what they'll do!

Please Log in or Create an account to join the conversation.

ACMOC

Antique Caterpillar Machinery Owners Club

1115 Madison St NE # 1117

Salem, OR 97301

support@acmoc.org

"I became a member recently because the wealth of knowledge here is priceless."

- Chris R

"I also joined a year ago. had been on here a couple of times as a non-member and found the info very helpful so I got a one year subscription (not very expensive at all) to try it out. I really like all the resources on here so I just got a three year. I think its a very small price for what you can get out of this site."

- Jason N