- Posts: 34

- Thank you received: 0

ACMOC Membership Benefits

- FREE quarterly magazine filled with content about antique Caterpillar machines

- FREE classified listings

- ACMOC store discounts and specials

- Full Bulletin Board Access

- Marketplace (For Sale/Wanted)

- Technical Library

- Post attachments

$44 /year ELECTRONIC

$60 /year USA

$77 /year International

(pictures) farming with steel tracks

Please Log in or Create an account to join the conversation.

Hi your pictures get more dramatic with the marvelous engineering feets of water conservation. one question the levelling hydraulics on the JD harvesters are they manually operated as you travel or are they automically operated by the machine. Thanks N H F. Atlas

They are automatic, Atlas, with a manual override. There are two speeds in the

auto position.....a slower speed for gradual slope changes, and a faster speed if the slope changes more rapidly.......and for emergencies. The manual overide uses the high speed of the leveler. A switch selects between 'auto' and manual.

A separate switch moves the machine either left or right......if the first switch is

in 'auto' and lay the machine over to the right (the machine's right) like this:

When you release the override switch, the 'auto' function brings the separator back to level.........like this;

Had the first switch been set to 'manual' ( essentially off for the automatic circuit) then the separator would have stayed in the last position.

Here is one example .......unloading on the go here, with the grain cart to the

uphill side. The operator had to switch off the 'auto' setting, lay the machine

over to the right a bit to allow the cart to move under the unload tube. He

then manually layed the machine back to the left some. He left the 'auto'

setting off while unloading so that the combine didn't level into the cart while

unloading. When done & the cart cleared out, he returned the control to the

'auto' setting:

Another trick is to use the override to 'lead' the combine when turning.

Heading across a slope leveled to the left as seen here:

When turning to go back where the machine will be leveled the other way,

you can pull kill the auto setting and start the machine leveling to the right

before the auto setting normally would. You 'get out ahead' of the leveler that way, then return to the auto setting. This was more important on the

smaller older machines like the 95-H.....the bigger wider stance machines like

the 9760 seen here or NIF's 6622's are a lot safer to turn and it's pretty

standard to leave the machine in the auto setting. Still nice to have the option however. Here the 9760 has turned around and heads back, leveled

the other direction for the return trip.

Please Log in or Create an account to join the conversation.

Please Log in or Create an account to join the conversation.

JD a few years back decided to get out of the (What they called Hillbilly) leveling machines because they built only about 150 a year.

This has been a great thread. I wonder if there is some way to publish it.

9U(2), 5J, IHC544, Ford860

Please Log in or Create an account to join the conversation.

Jim

Please Log in or Create an account to join the conversation.

More great pictures, are there any problems with the crop augering up hill in the header or feeding in the feederhouse on such steep slopes?

Jim

I have had 'em on as about as steep as it gets with very little trouble:

A shot of one of the neighbors....down hill .......and giving the edge a little room

so as not to slide off......

Nearly at the max on the leveler for the 1670 (48%) here. Note the left side

driver.....the ladder had to be modified for the hillside machines to allow for

this.

Leveled the other way......last step off of the ladder is now a doozie.....

things;

Please Log in or Create an account to join the conversation.

Hi your pictures get more dramatic with the marvelous engineering feets of water conservation. one question the levelling hydraulics on the JD harvesters are they manually operated as you travel or are they automically operated by the machine. Thanks N H F. Atlas

Visual aid time Atlas. All of the leveling systems in use today are electric over

hydraulic. On a 6622 like NIF's, or my old 95-H or 6602, a water/antifreeze solution is used...water runs down hill as the separator goes out of level...

trips a micro switch which turns on the hydraulic valves that level the machine.

The first automatic control for hillside machines was developed by Ray Hanson

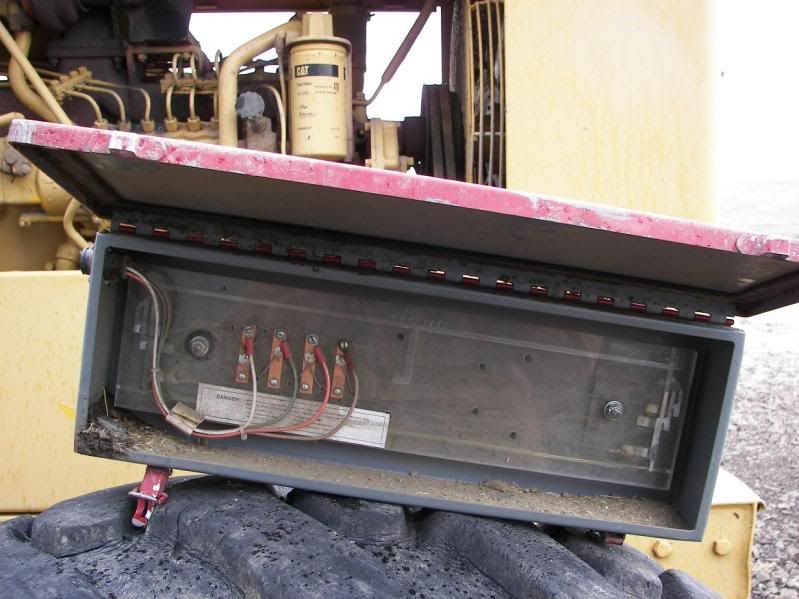

& installed on pull type machines ( most pulled by yellow paint) His control box used mercury. Same idea.....machine level, everything is off. As the machine starts to tilt, the mercury in the control board moves to the low side (of the board) and completes a circuit, a solenoid opens up the proper hydraulic valve & the machine levels. Here is a shot of a Hanson control box.....happens to be off of a IH 1470, buts basically the same Mercury board that Ray invented wayback when:

Since it's from a 1470 ( with two speed leveling) there are 4 contact points,

two on each side. When the separator tilts a little ( say to the right) the first

contact trips on , which opens up the valves to the low speed side of the

leveler. If the slope change is greater, the second set of contacts is triggered, and the high side (faster) side of the leveler kicks on. So, lets

say it triggers the fast side.....you will feel the machine level pretty rapidly.

As it comes back to level, the fast side contacts go off, and the slow side

finishes the leveling. The early versions had only the fast side ( one contact oneach side) and they could rock the operator around pretty good over the

coarse of a long day. So......the two speed set up was developed to smooth

things out.

Compare the shot of the board above to this one......I tilted the box to show

how it works. In this shot, the Mercury has flowed to the right had is completing the circuit. In the center of the Mercury board is a reservoir for

extra Mercury.....you could adjust the total system speed by adding or subtracting the amount of Mercury in the active part of the system. Too little

Mercury in, and the leveler would be slow( takes more time for the Mercury

to reach the switches) Too much Mercury in, and the leveler becomes over

sensitive....it hunts back & forth trying to keep the machine level. So, the

adjustment on the Mercury level turns in to a Goldilocks deal.........

.....has to be just right.

I had one of Ray's boxes on a IH 160 pull type that I pulled back in the mid

70's.

The control box operated the rack & pinion leveler on the combine ( ie, no

hydraulics) but the Mercury board was virtually the same. The first SP

combine that we had was an Gleaner AH ( circa 1958) The leveler control

on it used the same exact control board.

Please Log in or Create an account to join the conversation.

- North Idaho Farmer

-

Topic Author

Topic Author

- Offline

- Elite Boarder

- User

- Posts: 224

- Thank you received: 0

The only time I usually touch it when harvesting is unloading in the trucks on a hillside, nice to be able to lean down to get closer from the uphill side or in some cases (did this alot with the shorter 95s but not so much the 22s) from the downhill side I will switch to manual and bump it to the right to keep the unloading auger from hitting the truck.

But usually you can cruise right along and let the automatic leveler do its job and keep the separator level to maximize cleaning capacity.

Please Log in or Create an account to join the conversation.

- North Idaho Farmer

-

Topic Author

Topic Author

- Offline

- Elite Boarder

- User

- Posts: 224

- Thank you received: 0

98J- I actually didnt get a chance to look at that device on the 7722 as I had been looking at other things and just walked up beside it quickly and snapped that picture and it wasnt until I got it on the computer that I noticed it. I would suspect you are right in your thinking as I have seen something similar before on a different machine.

Please Log in or Create an account to join the conversation.

Please Log in or Create an account to join the conversation.

ACMOC

Antique Caterpillar Machinery Owners Club

1115 Madison St NE # 1117

Salem, OR 97301

support@acmoc.org

"I became a member recently because the wealth of knowledge here is priceless."

- Chris R

"I also joined a year ago. had been on here a couple of times as a non-member and found the info very helpful so I got a one year subscription (not very expensive at all) to try it out. I really like all the resources on here so I just got a three year. I think its a very small price for what you can get out of this site."

- Jason N