Apologies in advance for such a long post! This post summarizes the work done over the last six weeks. I will try to keep to smaller/more frequent updates going forward.

Several months ago I purchased D6 5R4638. The previous owner passed away last year, and his widow decided it was time to sell. She has been very kind to let me work on the machine where it is, in preparation for moving it. It's at the end of a 1.5 mile dirt road, at the top of a steep hill. So far I can't find anyone willing to drive a trailer up to the machine, so I'll probably have to walk it down to the paved road and get it on the trailer from there.

This is my first Cat, so I've been watching a lot of youtube - especially squatch253. Thank you squatch, without your channel this would simply be impossible! (I have also really enjoyed Andrew Camarata and Marty T.) I've also been reading a lot of posts on this forum, which has been invaluable. I got the full manual complement from Jensales - owners, 4600 diesel service, chassis service, and parts.

As some forum members identified in another thread, the machine has a non-cat light-weight blade possibly intended for silage, which is mounted on some version of a Cat 6 toolbar. (I know the machine was used in conjunction with a grader for road maintenance, and I suspect it was also used for snow removal.)

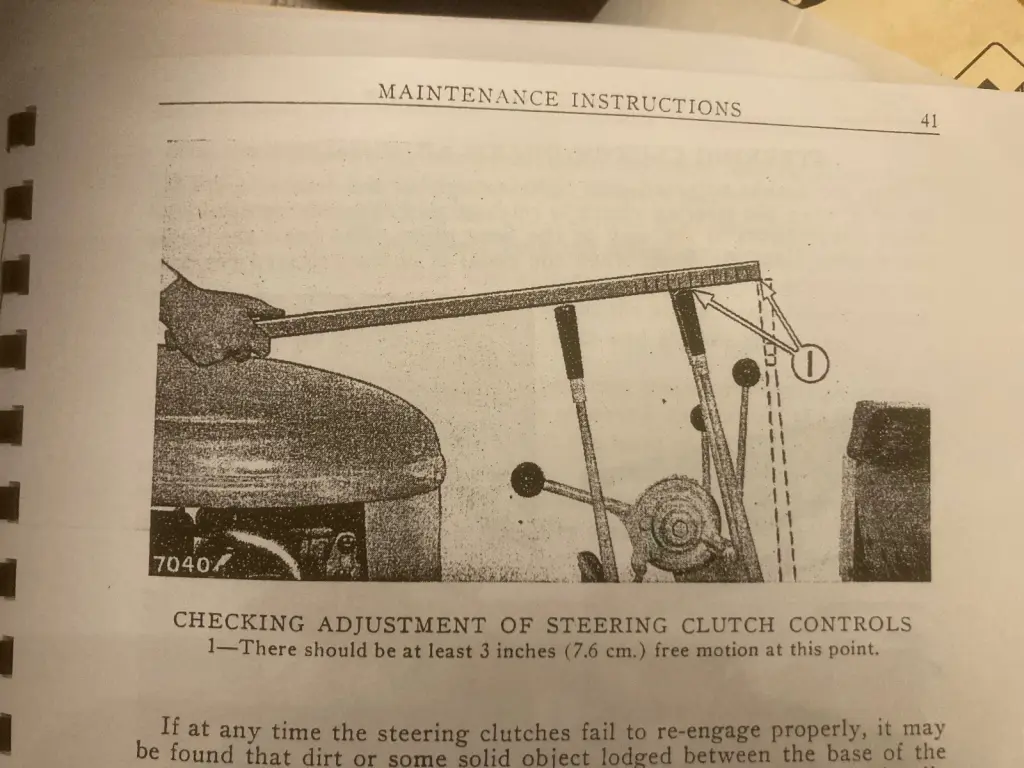

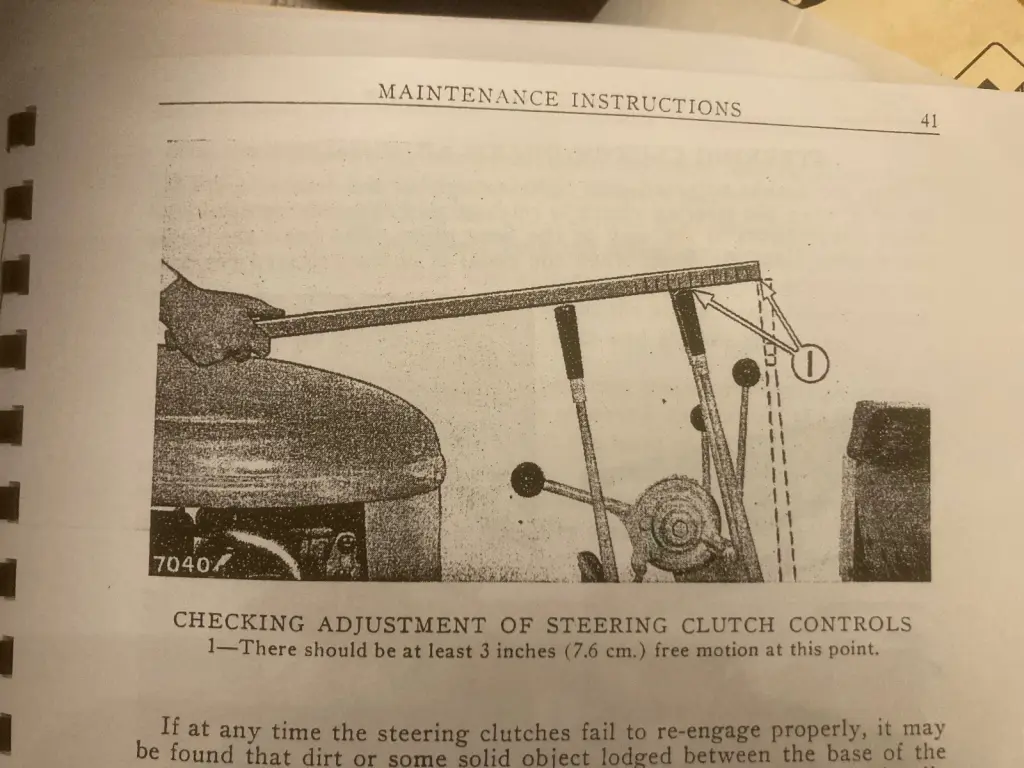

The previous owner last started it about two years ago, but didn't drive it at that time. I couldn't find any maintenance records, so no idea about oil changes, fuel filter changes etc. There was a bookmark in the Servicemen's Reference Book about steering clutch adjustment, so obviously that was on his mind.

The first several visits, the pony didn't run consistently enough to bother with starting the diesel. The third visit, a friend of mine disassembled and cleaned the pony carb. I had noticed the pony air cleaner was entirely missing, so for the time being I put a lawn mower air filter over the carb air intake with bailing wire. Crude, but certainly better than leaving an open butterfly! With those updates and some carb tuning, the pony ran strong enough that we got the diesel started up! But when I tried to move the machine, the engine lagged hard. We called it there.

A few days later, we went up again. In the interim, I re-watched several videos about how to drive a 9U (there's really nothing I can find on the 5R other than some starting videos, but the chassis on the two models is mostly the same). This time, I left it in first gear, and just did nudged it forward, back, forward, back, until the brakes broke free and it actually moved. At first it wouldn't turn at all. I got the left steering clutch broken free first. Eventually I was able to turn right, but the action was inconsistent. I would pull on the right steering clutch as hard as I could and step on the brake as hard as I could, but it would only turn sometimes. (Truth be told, it was my first time ever operating a dozer, so I didn't really know what to expect!)

In the intervening few weeks, I've been doing some other checks and maintenance that I probably should have done before ever starting it. I drained the fuel tank and fixed the drain petcock. The fuel looked good, and the tank is clean. Little if any water and/or dirt. I checked all the fluid levels as specified in the owner's manual: steering clutch booster (significantly low), starter engine clutch (ok), diesel injector pump (ok), diesel and pony crankcase (both ok), transmission (significantly high). The left final drive was low (to about the height of the upper drain plug), and the right final was full to the top but very thick, goopy, and milky.

I drained the oil from both final drives, and filled them with diesel. They've been soaking a few days now. The left one leaked down to the level of the upper drain plug, but it was too gross today to lie on the ground and look where the leak was coming from. (It rained a lot yesterday, and I spilled A LOT of diesel on the ground the day before haha.) If I remember to bring clean cardboard tomorrow I will take another look.

Today I drained the fuel tower, and changed the fuel filter elements. There was definitely some water in the bottom of the fuel tower, but not too too bad. I rinsed out the fuel tower with mineral spirits, and a bunch of muck came out. I didn't take off the hood, so I could only see the top few inches of the inside of the fuel tower, but that section was pretty clean. The lowermost gasket (I think at the top of the transfer pump) weeps a bit, but I don't think I will bother with replacing it right now.

My plan for tomorrow is to drain the injector pump, then prime the fuel tower and injectors, then start the machine and drive it for a few minutes. Then I will drain the finals and fill them with SAE 90, and also change the pony crankcase oil.

Additional planned next steps: change the diesel air cleaner oil and wash the filter elements, wash the steering clutch compartments with diesel, adjust steering clutches, change crankcase oil and oil filters.

I am really hoping to fix the "turning right" problem before moving the machine to its new home. It's going to a property where the access is a 20 foot wide L-shaped dirt driveway. I have to make a 90 degree right at the end of it and get through a 16' gate, but the neighbor's well is right there on the other side of the fence!

Any and all pointers/commentary welcome and appreciated!