- Posts: 235

- Thank you received: 39

ACMOC Membership Benefits

- FREE quarterly magazine filled with content about antique Caterpillar machines

- FREE classified listings

- ACMOC store discounts and specials

- Full Bulletin Board Access

- Marketplace (For Sale/Wanted)

- Technical Library

- Post attachments

$44 /year ELECTRONIC

$60 /year USA

$77 /year International

- Forum

- Antique Caterpillar Machinery Owners Club

- DISCUSSION

- Barndominium with shop space for my equipment, need ideas for floor fixtures.

Barndominium with shop space for my equipment, need ideas for floor fixtures.

- steeltracs

-

- Offline

- Elite Boarder

- Member

Please Log in or Create an account to join the conversation.

Yes, very important.Most important is that you install a vapor barrier under the slab, heated, insulated or not !

Please Log in or Create an account to join the conversation.

I use food grade belting here. Pretty easy to handle and durable, not has heavy as some rubber belting but tough.

If you plan on repair work, anchor pots/points in the cement floor strategically place would not be overly expensive.

How about grated floor drains?

Good washrooms/restroom/breakroom/office space...

Air compressor should be placed somewhere to minimize noise, or outside in an enclosed area.

No such thing as TOO BIG of a building. Even with a mezzanine for extra space, one can fill a building easily.

Plenty of outlets 120/240 3 phase for welders, good lighting

Make it so you will be comfortable working inside of it, so plenty of insulation and such a must.

If you have space, leave options for future expansion.

Following this thread to get great ideas from others as well, so thanks for asking. JM

Please Log in or Create an account to join the conversation.

- ctsnowfighter

-

- Offline

- Platinum Boarder

- User

- Posts: 1002

- Thank you received: 502

Never enough outlets or lighting, and as one gets older, things become much more difficult - something that one needs to consider.

Lots of great ideas here, glean what fits your needs, climate and budget.

Think about the floor - you will be on it all the time you are in the shop!

Environmental issues --- Many Regulations --- Secondary Containment for fuels, oils, etc and meeting the fire codes! Storm water runoff is becoming a huge issue too -

One may need some sort of separators for floor drains. Do you plan on having a "wash rack" with steam or hot water pressure washers?

Waste Products - Hazardous Materials Storage --- many things that were not thought of years ago are now required.

City or Municipal Codes if you are within those jurisdictions - $$$$$$ to hook up to utilities.

Scary thoughts but must be approached and thought through.

CTS

Please Log in or Create an account to join the conversation.

As far as power, the building will not have 3 phase power. Though I do want at least a mill and a lathe someday, so have to figure out a phase converter setup. I also am planning on a 5 ton bridge crane in a 48ft x 48ft area of the shop where the 14ft wide x 16ft tall doors are located. The crane would also require 3 phase power. I have 3 phase power available at the road, but I already installed 240V 400 AMP service years ago, 600ft from the road, it was almost $10k to install that. Not sure I want to install a second electrical service and have two power bills per month when I would probably not use 3 phase power all that much. So I think a phase converter would work there. I do know that actual 3 phase power is better than having a converter, but this is a one man shop for personal use, not sure the expense of having a second electrical service can be justified. If this was going to be a business/livelyhood then sure.

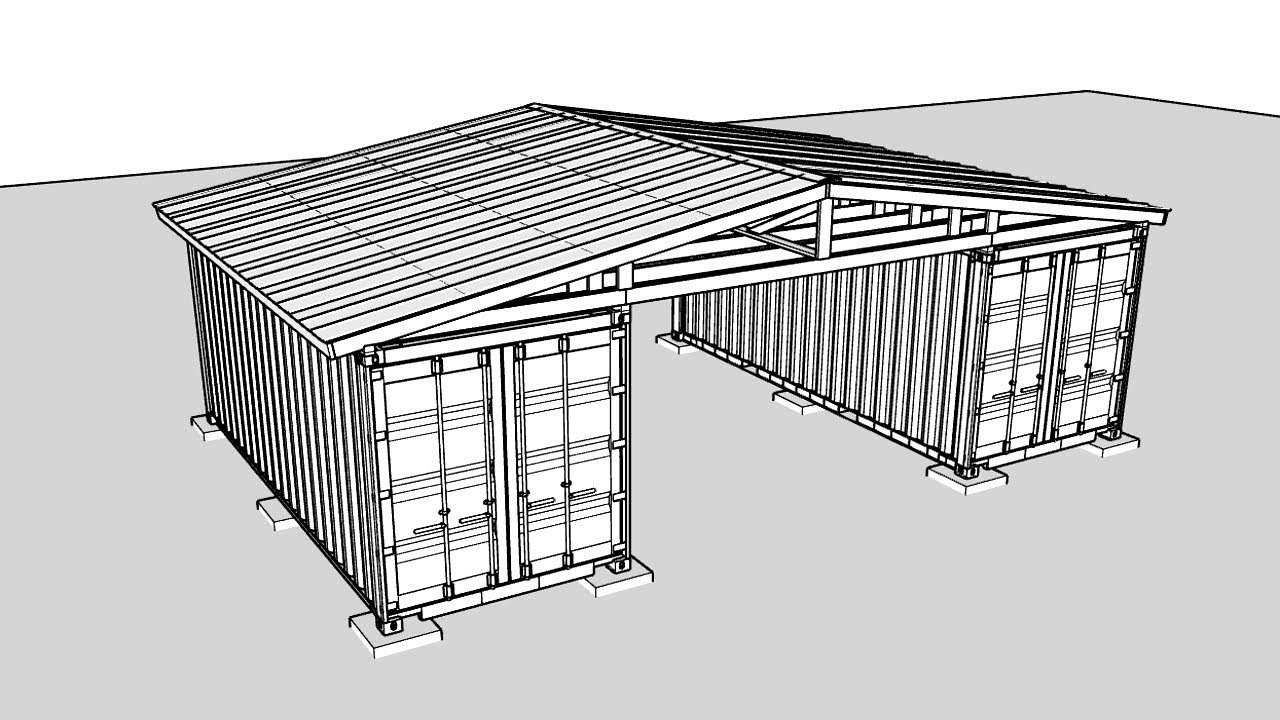

I currently have 3 shipping containers. I plan to buy one more and stack them 2 vertically, spaced out about 40 ft, and have a roof between them. This will give me a 40ft x 40ft x 16ft tall parking area for my equipment under a roof as opposed to exposed to the weather as they have been for the last ~20 years. I'd like to "restore" both my D6C and 225, as well as some other equipment I have. Plus I am always looking on Marketplace for other old iron toys for projects. Once I restore a piece of equipment I no longer want them exposed to the sun/rain all the time.

I'll have room to expand the building toward the west if I really need to. And I already have 2 driveways, someday they will be connected and I'll be able to have trucks pull through to deliver any other toys I buy etc.

I did think about doors to allow pulling through, but again, I am one person and this is not going to be some busy repair shop for customer machines, it's just for my tinkering. So I'd rather have the shop floor and wall space for tools, benches and cabinets, not as easy to have that if you have to keep clear for a pull through setup.

Here is a site layout for thos interested: Site Layout

Long term plan is for a log cabin in the upper right area of that layout where the east driveway ends, Cabin would be right on the water of the ponds etc. Connected to the same septic system, hence the reason that septic field is so large. I would remodel the second story living space of the shop to non-living space, more shop area of somekind etc. In my municipality I am not allowed to build a barn before a structure with living space. Living space has to come first, hence the reason I am doing a Barndominium. I get my shop first as well as some living space. If I really want a separate house someday I can do that. However, I am not married so that will probably never be neccessary. Though the traditional log home may be another project I want to do for projects sake not for woman's sake...

Please Log in or Create an account to join the conversation.

- trainzkid88

-

- Offline

- Platinum Boarder

- Member

- Posts: 2120

- Thank you received: 788

the other way is have compacted roadbase or better yet 40-70mm ballast material for where the tracked machines are so it doesnt matter you just rake it smooth and unlike road base its doesnt get muddy.

a servicing pit is a good addition beats crawling on your guts under a machine or the axles of a prime mover.

as others suggest i would make the shed drive in drive out this makes life easier i would have the shed long enough that you can load/unload a machine off the truck while its inside the shed doing this in the rain,mud etc is not fun.

if you can afford it a overhead crane is a godsend when working on machinery. it can be as simple as a girder riding on rails that is manually traversed the length of the shed with a girder trolley on that holding a electric chain block.

a must have is your own washroom in the shed as it keep she who must be obeyed happy as you can clean up before going inside. also it reduces the amount comfort breaks cut into "playtime" side bonus you can leave the seat up without complaint. a kitchenette is also a nice addition gotta have somewhere to have smoko and make a cuppa. also a old oven comes in handy when mounting gears and bearings you can warm them first to make press fits easier.

as for doors the bigger the better and roller doors are a good choice they dont take up much room and you can adjust the amount there open to control airflow etc

you can never have enough power outlets same with compressed air supply you want outlets throughout the shed. nothing worse than hoses and leads running everywhere over the floor etc they get damaged to easily and are a trip hazard.

and remember if you think its big enough its not.

the accumulation of stuff grows to suit the shed space you have.

Please Log in or Create an account to join the conversation.

- trainzkid88

-

- Offline

- Platinum Boarder

- Member

- Posts: 2120

- Thank you received: 788

you mention shipping containers have a look at the container dome shelters they mount on 40ft containers and if you get high cube containers you have a extra foot of head clearance.

there are several companies that convert containers into living quarters and its possible to join a couple together to get a larger space. some people locally built their house using old containers and now its nearly finished externally it hardly looks like that is what they used.

one thing about those phase changers is cnc machines dont like it as its not clean power it affects the stepper motors used on cnc machines. another way is to have a suitable 3phase generator to run those machines as needed. i would also have a look at 2 phase 480v power.

Please Log in or Create an account to join the conversation.

Yeah, I already have the 240V 400A power installed. It's ~700 ft from the road with conduit underground from the ~7600V transformer on the pole at the road to the 240V transformer at my meter pedestal. Not sure the power company can pull 3 phase through that conduit 700ft. Though I did use larger conduit than they recommended, 2-1/2" SCH 80.you can probably do the 3 phase the way we did it at my parents. the electrical load for the house and shed is split over the 3 phases and the shed has a 3phase circuit for the bigger workshop machinery. this means we get very good single phase power. the utility company supply us on a hobbyist rate and its no more expensive per unit used as if we had only single phase. talk to your electric distribution company and a electrician first. when we upgraded at my parents they ran a new cable from the pole to a new connection point insulator and fitted the 2 extra meters and additional breakers to the existing switchboard. and simply added extra cables into the conduit run to the sheds(we had planned ahead and used larger conduit to begin with)

you mention shipping containers have a look at the container dome shelters they mount on 40ft containers and if you get high cube containers you have a extra foot of head clearance.

there are several companies that convert containers into living quarters and its possible to join a couple together to get a larger space. some people locally built their house using old containers and now its nearly finished externally it hardly looks like that is what they used.

one thing about those phase changers is cnc machines dont like it as its not clean power it affects the stepper motors used on cnc machines. another way is to have a suitable 3phase generator to run those machines as needed. i would also have a look at 2 phase 480v power.

As I said, I already have 3 containers and threy are standard height, not high cube. So when I stack them I'll have 16ft tall walls. The upper containers would have stairs up to them and used for storage of lighter stuff. The lower containers storage for larger/heavier parts etc.

I would probably try to build my own roof as opposed to buying the really tall domed roof.

Please Log in or Create an account to join the conversation.

- trainzkid88

-

- Offline

- Platinum Boarder

- Member

- Posts: 2120

- Thank you received: 788

yes we did the same thing with a pair of containers but here's something to think of, we made our roof free standing the containers are simply under the roof this way if they rust out they could be dragged out and you could drag a new one into place. remember old containers have already had a life unless you buy one way trip ones which are much more expensive and harder to get anyway.

Please Log in or Create an account to join the conversation.

I did most of the work on the power install, power company set the transformer and pulled the single conductor, I did the trenching, laid conduit and everything else. At the time I made the decision to go with 240V single phase instead of 480V 3 phase. I intended to build a house. However now that I am set on my shop/house, I wish I would have went with 3 phase. 3 phase power is at the road. It's just a question if the power company can pull the 3 leads needed through the conduit already in place or not. Plus, how much will it cost me. I would have to replace all the equipment on my meter pedestal.yeah thats a fair distance, that must be heavy cable if you can get 400amps 212 metres from the pole. they still might be able to simply pull a extra conductor through that conduit. ask your electrician. one way to tell if it might be possible is how many wires run to the grid side of the transformer is it 1,2 or 3 if there's 3 wires then there is 3 phase available from the grid.

yes we did the same thing with a pair of containers but here's something to think of, we made our roof free standing the containers are simply under the roof this way if they rust out they could be dragged out and you could drag a new one into place. remember old containers have already had a life unless you buy one way trip ones which are much more expensive and harder to get anyway.

Power Install

It may be cost prohibitive to change over, but definitely want to investigate before I build.

Please Log in or Create an account to join the conversation.

- Forum

- Antique Caterpillar Machinery Owners Club

- DISCUSSION

- Barndominium with shop space for my equipment, need ideas for floor fixtures.

ACMOC

Antique Caterpillar Machinery Owners Club

1115 Madison St NE # 1117

Salem, OR 97301

support@acmoc.org

"I became a member recently because the wealth of knowledge here is priceless."

- Chris R

"I also joined a year ago. had been on here a couple of times as a non-member and found the info very helpful so I got a one year subscription (not very expensive at all) to try it out. I really like all the resources on here so I just got a three year. I think its a very small price for what you can get out of this site."

- Jason N