I don't know about Carco specifically but the usual method is a large ferrule (L-7) for 7/8 either fits into a pocket that traps it in the side of the drum flange and may or may not also use a bolt clamping device or wedge device of some sort.

Are you sure you want to. If you hook on to something that turns out to be a bad idea you;ll want to get rid of that cable before it takes you over with it.

Dear Mike, I have seen just the opposite here in the Northwest. Many of the cat skinners will clear steep hillsides while yarding their cats over the hill side at the end of their winch cable. Fire look outs and other view points are common places that need a good cable to keep you from tumbling away down the hill side. This is one time that you do not want the cable to come lose from the drum when you have accidentally spooled out too much cable. Also, the nuisance of having the cable come lose from the drum when you accidentally spooled out too much cable also becomes a pain when you are in a hurry. It is always a good practive to leave at least a few wraps on your drum when you start your pull. The last layer of cable on the drum that has become lose, is a bear to wrestle back onto the drum because it usually has a spiral twist in it that never wants to be fed back onto the drum smoothly. A reminder here for the novice, there are different types of cable to use on your drum. I always use the next smaller diameter cable which has the greatest strength available. I always use the steel cored cable that has been rolled for maximium strength. It has over twice the strength of the same diameter cable with only a rope core and not rolled. Being the next size smaller diameter, you can get a lot more cable onto your drum. Because it is stiffer, and it is about as easy to handle as the next larger diameter rope cored cable. It also costs a little more too. Never spool a cable back onto your drum only by yourself while holding onto the end of the cable. If you have to, make sure that you are not any closer than twenty feet to your cat when you let go of the cable. Usually if I have a lot of cable spooled out and I have to winch it back in, I will latch onto an old tree stump and let the winch reel the cat back to the stump. It usually winds up nice and level while a good pull is on it. A widow living near by, sold her husband's D8 last year because his glove became entangled in the lose wires on the winch cable. He was working alone and he was spooled onto the drum. It was pretty ugly. Also keep in mind, in a wink of an eye, a lose cable flying through the air can cut a man in half. A winch is a great thing to have, but practice winch safety in every move with it.

hello Philip , i could not find a good pic to post but were the welded piece is on your winch ,there should have been the a hole that holds the cable in with a ferrule ,most likely someone unwound the cable to much breaking it out of the drum .there should always have two turns of cable left on the drum.

you will have to weld another anchor point to the drum to hold the wire ,

good hit is paint the last 3 turns of the cable so you can see when it is coming of the drum and not pull on the anchor point.bruce oz

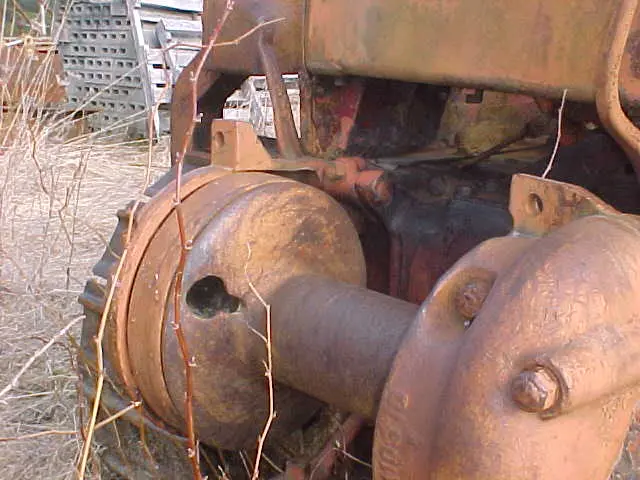

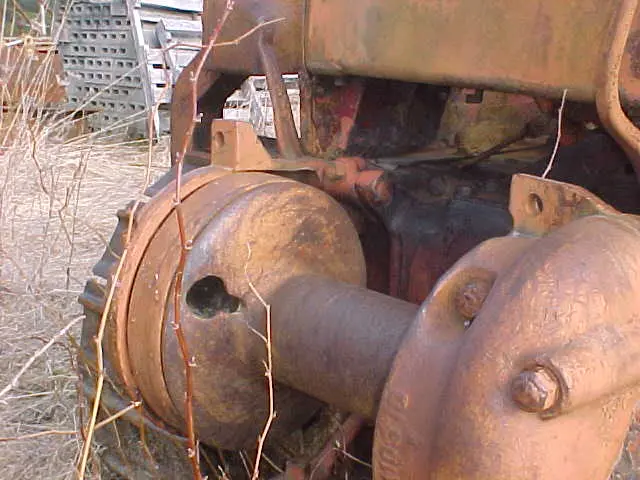

This is what the cable attachment point looks like on a Carco #6 winch

George

Whoops, didn't attach

I have a Carco winch on my D7 3T. The cable attachment doesn't look like that one of trucker 1. I can't really see what is on Philip's winch. Mine has a notch in the core of the drum that will hold a ferrule about 2" in diameter, with a smaller notch leading into it from both directions for the cable, so it can be spooled over or under. Since it is a logging winch with ratchet brake, I don't see why anyone would want to spool it under.

Anyway, mine is as simple as finding a cable shop that can swage a 2 in. ferrule, and then dropping the ferrule in the slot and start winding.

If you actually feel that you will use all the cable that will fit on the drum, then go ahead and put it on. But if in reality your max distance is going to be less than 50 feet, then only put that much on plus a little more. When you wind cable on tight it looks nice, but every time you feed it out it loosens on the drum which when pulling will make it tangle plus your never perfectly lined up with what your pulling on which makes the cable bunch up on the ends of the drum causing it to fray and wear even more. In a short period of time all that cable will be worn, twisted and frayed. Sitting outside on the drum rotting/rusting in the elements will do that expensive purchase no good also. Put on what you need and when its worn out or ruined, then put on another length of cable.

PS

Those hairs/wires sticking out of a frayed cable poke/inject into your hand through a glove all the dirt and crud which doesn't bleed out to wash that stuff out. OW!!!

If you don't want to swage a ferrule on, go to a shop that specializes in rigging work. I use what's called a speed knob or quick knob, it's a three part affair that the ferrule goes over the cable, then there's a two part wedge that you unlay a few inches of cable, thread the wedges in and pull the cable back into the ferrule. They're a bit expensive but the best part is they're reusable.