Reply to ccjersey:

The owners manual I have for a similar age D2 says initial setting 1 turn out on the idle speed and 1/2 turn out on the high speed.

I wonder if it misses when you open the throttle because it's rich or lean? What does the smoke and plugs look like?

Have you tried to screw the high speed needle in a little bit to lean the high speed mixture? When it starts to miss as you push the throttle open, is the exhaust black or clean?

I'm guessing you have the idle mixture about right, but remember, you are adjusting the air that goes along with the gas flow through a fixed orifice, so screw the idle screw in to richen the mixture and out to lean it.

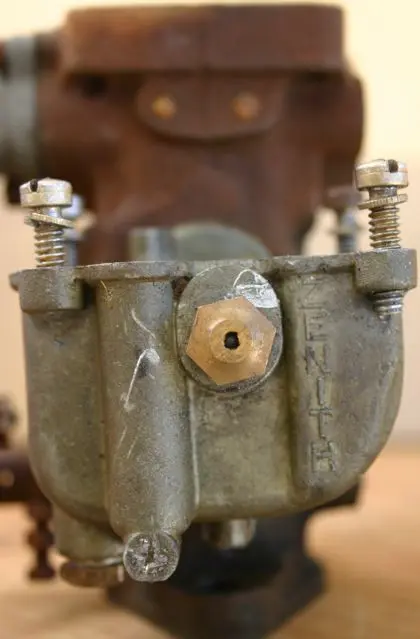

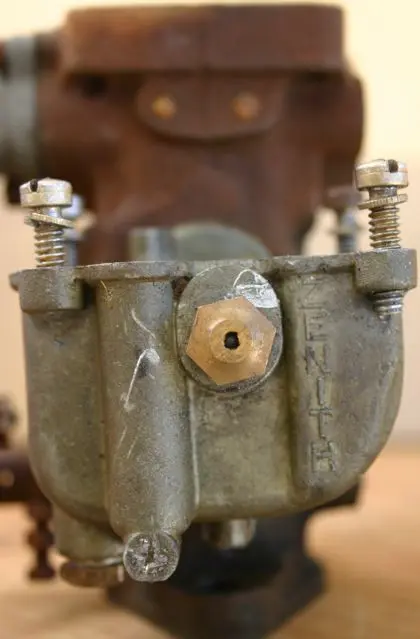

Can you get it to idle without the choke mostly/fully on? If not, somehow you still do not have good flow through the idle circuit. The idle discharge jet edb put pictures of would be a good candidate if you haven't driven it into the carburetor throat to check. See this thread

http://www.acmoc.org/bb/showthread.php?10971-pony-won-t-idle-down&highlight=

Does your gasket between the float bowl and the carburetor body have the center "bulls eye" in place?

Assuming of course the aircleaner is clean, because those little guys never get cleaned it seems, I'd start there at the air cleaner and check your inlet manifold too, then if I had really good fuel flowing to the carby, assume that there is crud in some of the carby passageways.

I find my RD4 pilot motor somehow collects water in the carby fuel bowl making it really hard to start and I'm starting to suspect the pot metal used to build those units is hydoscopic and draws moisture from the atmosphere.

Anyway, as Bernie and CCJersey will tell you, those little carbies have some narrow passageways that can only be cleaned by removing the solder plugs with a drill, it's not hard to do, and I used a .177 air rifle slug to block them up once the cleaning job was complete as they fit perfectly.

I've paid supposed experts to do work on my Cats expecting a job worth the $100 an hour they charged me, only to find the Apprentice earning $8.75 was given the job and you may find the carby shop never removed those plugs to clean it properly.

Someone here like "Billy" has the photo's of the plugs I'm talking about.

regards

Mike