I think either the wrong magneto or more likely a magneto cap problem allowing the spark to track between the two lead connections. Removal of the #2 lead could help isolate the #1 side so it gets a good spark.

When you say you swap the #2 over to #1, are you talking about swapping the whole lead or just one end. In the case of swapping the whole leads, something is surely suspect about the #2 lead unless you mean that you connect both leads again once you swap them and the original problem returns. After you swap the leads, if you remove the old #1 lead from the #2 cylinder will the engine rev up or not?

I think either the wrong magneto or more likely a magneto cap problem allowing the spark to track between the two lead connections. Removal of the #2 lead could help isolate the #1 side so it gets a good spark.

When you say you swap the #2 over to #1, are you talking about swapping the whole lead or just one end. In the case of swapping the whole leads, something is surely suspect about the #2 lead unless you mean that you connect both leads again once you swap them and the original problem returns. After you swap the leads, if you remove the old #1 lead from the #2 cylinder will the engine rev up or not?

If you swap the wires on a running D2/D4/D6 horizontal or an even fire vertical pony motor and it still runs, you definitely have spark jumping from terminal to terminal.

Your timing should be right or it wouldn't run on either one very well.

With spark jumping from terminal to terminal in the cap, you have a "wasted spark" ignition. The sparks occur at ~15 degrees before TDC compression #1 and TDC exhaust #2 and then at ~15 degrees before TDC exhaust #1 and TDC intake #2.

The jump must be easier one way than the other to cause the difference in performance when you swap the wires. Something about the epoxy is acting sort of like a zener diode, it resists current flow in one direction more than in the other.

With one of the odd fire verticals, I could see how the mag might be timed for the following cylinder spark to hit the leading cylinder plug, but that would put the leading cylinder spark into the intake stroke of the following cylinder (I think, getting my self confused here😆 and would almost certainly cause it to backfire through the carburetor.

Get a new cap and put it on there!😆

I think you've found your problem when you described the "magneto lighting strike" inside the cap that you filled with epoxy. It would have been better if you had ground the strike mark out as it probably carbonized the cap along that track. While a VOM probably won't show continuity due to the low voltage it uses, high voltage such as used in the mag will follow that track.

Back when I was young, we used to take a pencil and mark a distributor cap with a light mark from several of the plug wire towers either to each other or to the edge of the cap to the distributor housing itself. Sure causes some interesting misses (and noises) as the juice would arc along those marks 😆

Yup, get a new cap.

Mine did the same or somthing very simalar , end up being a worn impulse coupling. Make sure it snaps for both cylinders. Tim

I think you've found your problem when you described the "magneto lighting strike" inside the cap that you filled with epoxy. It would have been better if you had ground the strike mark out as it probably carbonized the cap along that track. While a VOM probably won't show continuity due to the low voltage it uses, high voltage such as used in the mag will follow that track.

Back when I was young, we used to take a pencil and mark a distributor cap with a light mark from several of the plug wire towers either to each other or to the edge of the cap to the distributor housing itself. Sure causes some interesting misses (and noises) as the juice would arc along those marks 😆

Yup, get a new cap.

[quote="ol Grump"]I think you've found your problem when you described the "magneto lighting strike" inside the cap that you filled with epoxy. It would have been better if you had ground the strike mark out as it probably carbonized the cap along that track. While a VOM probably won't show continuity due to the low voltage it uses, high voltage such as used in the mag will follow that track.

Back when I was young, we used to take a pencil and mark a distributor cap with a light mark from several of the plug wire towers either to each other or to the edge of the cap to the distributor housing itself. Sure causes some interesting misses (and noises) as the juice would arc along those marks 😆

Yup, get a new cap.[/quote]

Is this the best place to start for a cap ? Bill L at www.magnetoparts.com

I am in Australia so it has to be mail order.

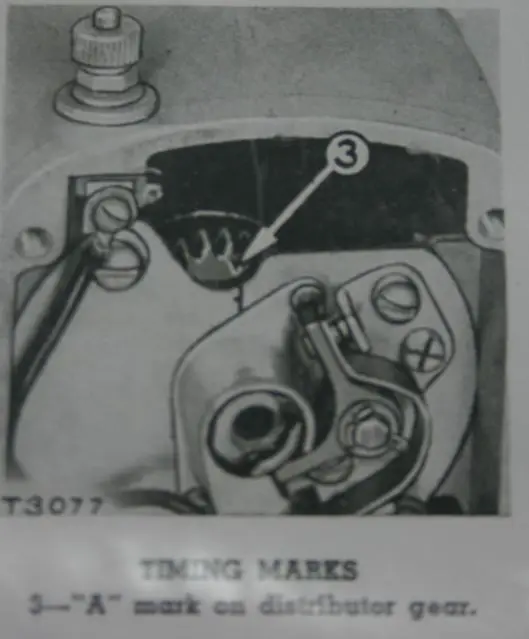

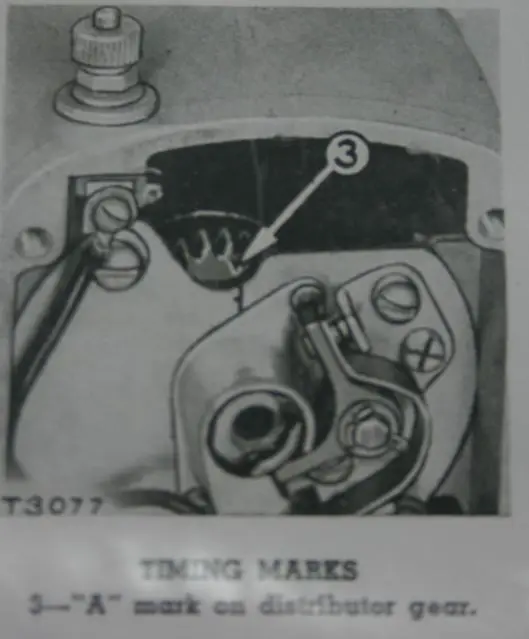

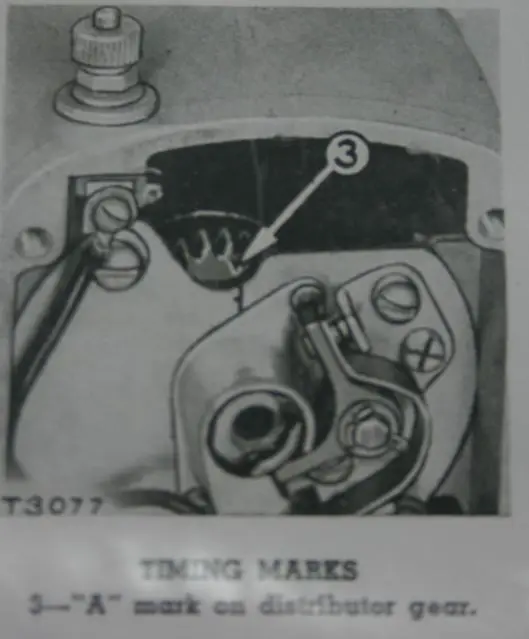

Have attached a pic before I filled it. I wonder if the epoxy is conductive itself. I will grind it out and have a closer look at the original short. What else can I fill it with ?

[quote="ol Grump"]I think you've found your problem when you described the "magneto lighting strike" inside the cap that you filled with epoxy. It would have been better if you had ground the strike mark out as it probably carbonized the cap along that track. While a VOM probably won't show continuity due to the low voltage it uses, high voltage such as used in the mag will follow that track.

Back when I was young, we used to take a pencil and mark a distributor cap with a light mark from several of the plug wire towers either to each other or to the edge of the cap to the distributor housing itself. Sure causes some interesting misses (and noises) as the juice would arc along those marks 😆

Yup, get a new cap.[/quote]

Is this the best place to start for a cap ? Bill L at www.magnetoparts.com

I am in Australia so it has to be mail order.

Have attached a pic before I filled it. I wonder if the epoxy is conductive itself. I will grind it out and have a closer look at the original short. What else can I fill it with ?