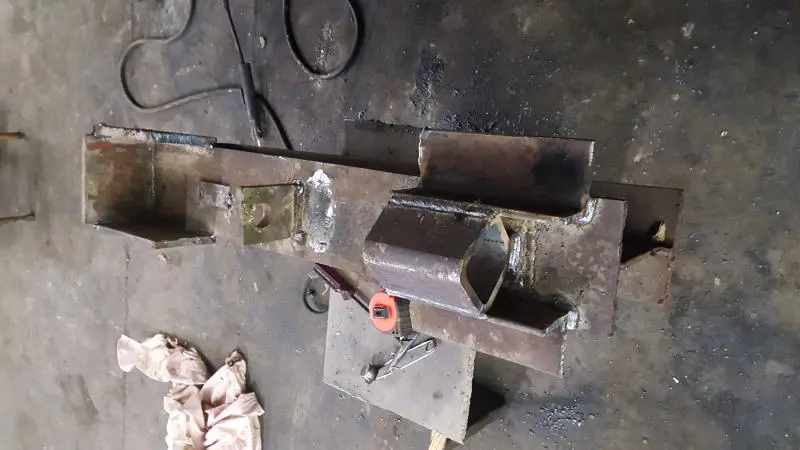

That looks good, I've often thought there should be a good garage type method for pushing out pins.

Did the 50 ton Jack struggle or push it right out? Seems like I've read the hydraulic pin presses are 100 tons. Either way you got it out . Might be one in my future, thanks

D2gary beating all day pin moved 1/16 usually once they move your home free not this one i put the jack on it and it pumped up and jumped 1 time a good 1/4 then stopped so i pumped it up again and smacked the bottom of the jig under bottle jack with a sledge and it shot out with 1 hit. The pin had also been welded on both sides and had to remove weld with a cone shaped carbide bur bit on the die grinder. But overall i think when i have another one to do the time spent making this was worth it. Not sure i would have gotten this one with just a sledge like normal

D2gary beating all day pin moved 1/16 usually once they move your home free not this one i put the jack on it and it pumped up and jumped 1 time a good 1/4 then stopped so i pumped it up again and smacked the bottom of the jig under bottle jack with a sledge and it shot out with 1 hit. The pin had also been welded on both sides and had to remove weld with a cone shaped carbide bur bit on the die grinder. But overall i think when i have another one to do the time spent making this was worth it. Not sure i would have gotten this one with just a sledge like normal

Very nice looking jig, only thing I could add to it would be a ring on the pushing pin to keep it centered on the jack ram. Do all you can to avoid exposure - hide yourself from possible failures.

I sympathize with those fighting master pins - remember a D7E and frozen pin - 16# double jack, and cutting torch, all day affair in 100 F weather, no shade! Two of us earned our pay that day!

I operated a fixed track press in a Cat shop - had a cylinder explode! 8" cylinder coming apart is not something you want to experience. (No, the packing did not fail - the cylinder walls came apart!) Same thing happened some time later on same side of press, both of us were extremely lucky we were not hurt!

Pushing pins, master or otherwise can be very dangerous, use all cautions possible!

CTS

That's why I like the split master pins on the D2 because once the plugs are out, they virtually push out by hand. I realize D2s are small potatoes but the current master pins are just those solid pins and they do not move easily like the split pins do

Not having the proper tools, nor skill, nor torch, but access to electricity, I used a Sawzall to cut my master pin and split the track on my old 17A. I cut the first side with one blade and about 10 minutes of sawing, thought I was pretty clever. For some reason, second cut took about 8 blades and about 75 minutes, but got it cut. There are always several ways to skin a cat.

Kelly D717A

I like the Press!

Resourcefulness usually does not fail in getting a seemingly impossible task done!

Now can you "press" it back in with the same rig?

Exothermic torch = done

New pin and dry ice $30

"One stick of dynamite....free"