Hi Peter,

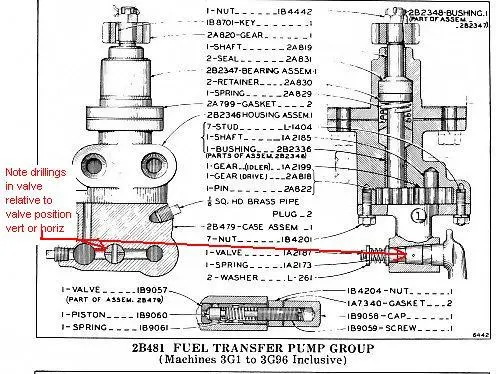

by my Diesel 75 and Diesel 40 Parts books only a small number of early units had these taps. The pix show that the tap has a small hole thru the valve in the down/vertical position and a larger drilling at 90 deg to the small hole when the valve/lever is in the horizontal position.. This would allow gravity to slowly bleed the system out of any open bleed ports in the filter housing and fuel pump bodies.

You should be able to bleed the fuel system either way IE :- pony not running with valve horiz. --big drilling in play and, pony running and main engine turning on de-compression/starting position, with valve vert. --small drilling in play.

Sorry I cannot find my Diesel 35/40 grey OMI so I could post better scans and descriptions. Parts scan below should help.

Your confusion is likely the reason this feature was dropped early on.

Hope this helps.

Cheers,

Eddie B.

thanks Eddie,

Was the purpose of the lever with the vertical and horizontal drillings to facilitate bleeding via gravity, do you think?

i feel like there's something here that i don't understand....

regards,

peter

Hi Peter,

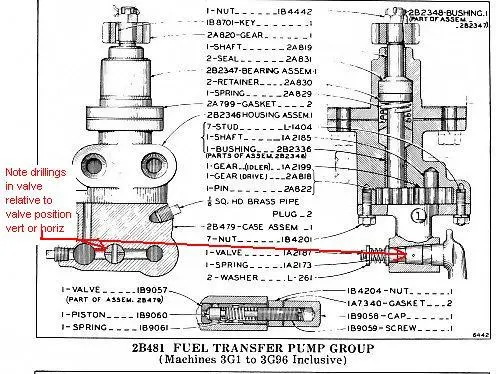

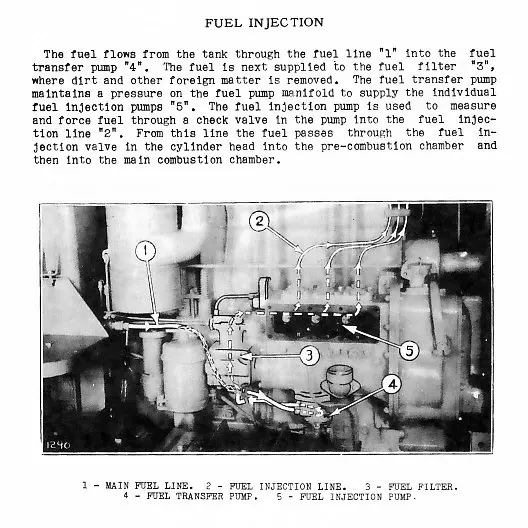

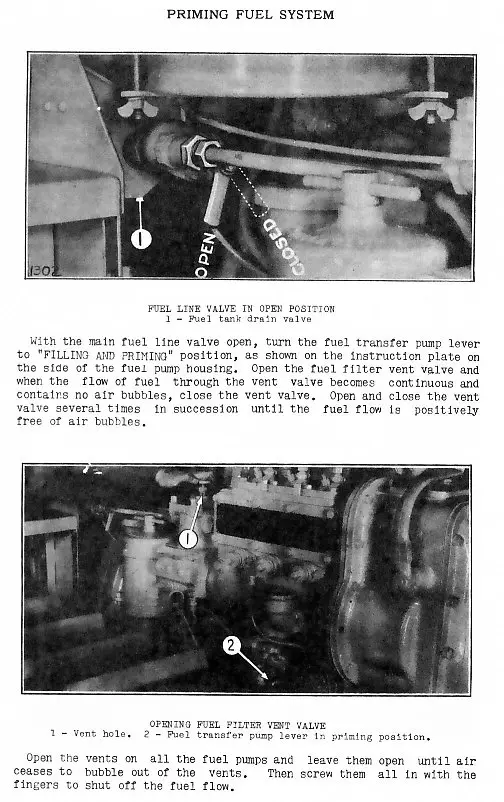

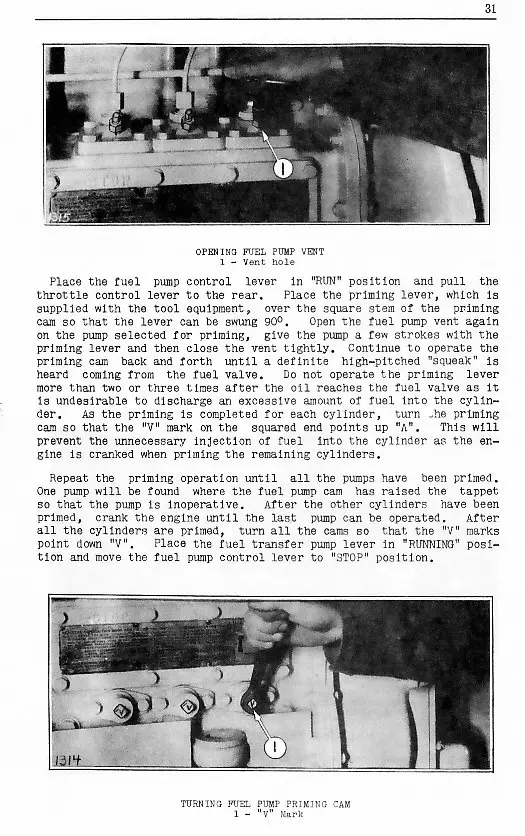

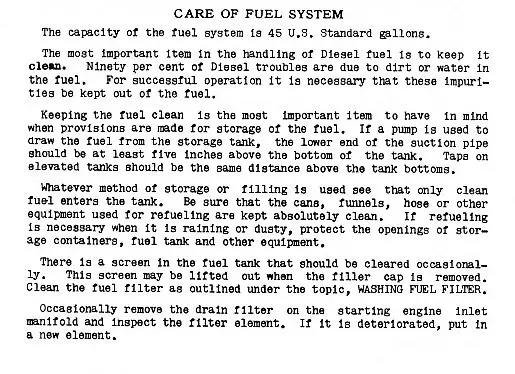

scanned below is the FULL section on "Priming Fuel System" from my Early Products General Instruction Book.

It is my understanding that the system is capable of being bled using gravity only when the large drilling--handle horizontal--is in the system. No doubt it would bleed thru the small drilling, if indeed it exists, but it would be terribly slow.

Without the drilling in the valve the normal path for fuel to gravity feed and bleed the system without the main engine being turned by the pony is thru the gear to housing clearances within the Fuel Transfer Pump itself--exasperatingly slow--

In the text scanned it tells us that the bleed instructions are on the Brass plate on the Injection Pump Side Cover.

In the last pic (Numbered 1314) I believe I can see the lever positions shown to the left behind the operators clenched fingers. Is this plate still on your machine?

Also scanned ,the first 2 scans, is text on "Care Of Fuel System" 1&2, which actually tells how to bleed the system by GRAVITY by turning the "Filling Priming Lever" to the horizontal position and then following the Vent valve sequences.

Hope this helps.

Cheers,

Eddie B.

Thanks Eddie.

There two drillings in the brass lever body, as you describe. one is tiny. I think we both now understand how the system is designed to work. The brass plate is on my machine, but only covers the two positions of the lever and a bunch of waffle about 'clean fuel' and 'don't lug the engine, etc...'.

Because my transfer pump leaks badly around the tapered brass lever (wear and a dodgey seal) i am in the process of remachining the pump surfaces and replacing the lever assembly with a blanking-plate. I'm guessing this is how later machines were produced...

I'll no longer have the ability to prime under gravity, but i should solve a bunch of other issues this way.

I'll report back.

Thanks again.

peter.[attachment=8503]!cid_74706DCD-ABB9-4207-A5AD-030DAD22493E.jpg[/attachment]

Hi Peter,

I feel you will need to blank the tapered valve port with a like tapered plug or you may not be able to build up fuel pressure as the fuel will just re-circulate around the valve passages.

I do stand to be corrected on this.

I guess you have tried to lap the valve in with a very fine lapping compound.

Cheers,

Eddie B.

hey Eddie,

i'm thinking that if the fuel was going to 'circulate around the valve passages' (with my blanking-plate installed), it would do that anyway. ie: it would take the path of least resistance and avoid the tappered brass valve altogether.

i'll let you know what happens...

rgds,

peter

Thanks Edddie B.

Have now installed and tested my modified Diesel 35 transfer pump. With the bottom half blanked off, the unit no longer leaks (no losing prime). I can still bleed right thru to the injectors under gravity (albeit slowly- dependant on the head of pressure ie: how full the tank is), and i have a steady 30 psi of fuel pressure (the pressure-relief valve got removed along with the 'priming lever'). I think the wear in the pump gears is actually helping me. I think it allows me to gravity-bleed and also means the pump can't generate too much pressure.

Every now and then we get a win...

Thanks again for your assistance. This forum is invaluable.

Peter.