Hi Joe,

be aware that if you try and order parts by year or ask questions here you will get no where as Caterpillar run an ongoing product improvement program and so update their machinery components and fit them as soon as they develop the improved parts.

Cat Parts Books have Serial Numbers at which the changes took place at and a machine with a S/No before or after yours may have different parts and cause us to give you incorrect data for repairs etc.

Your machine I take it to be a 17A D7.

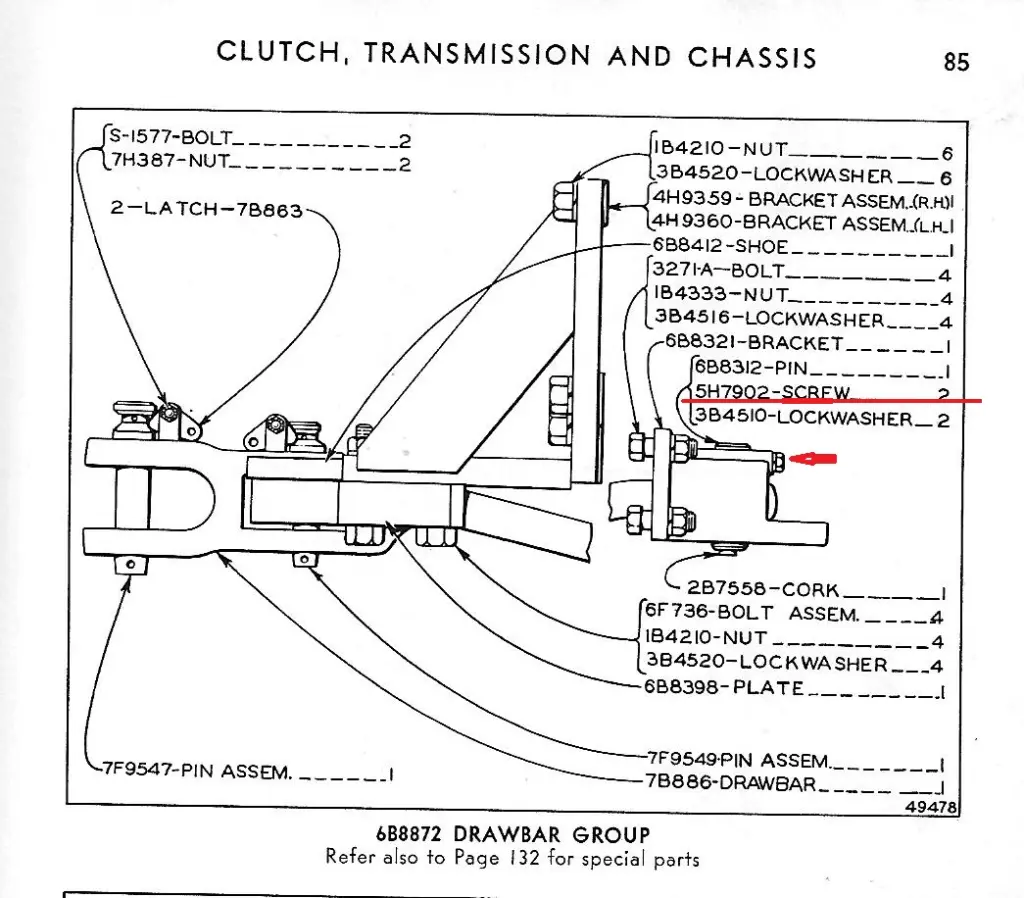

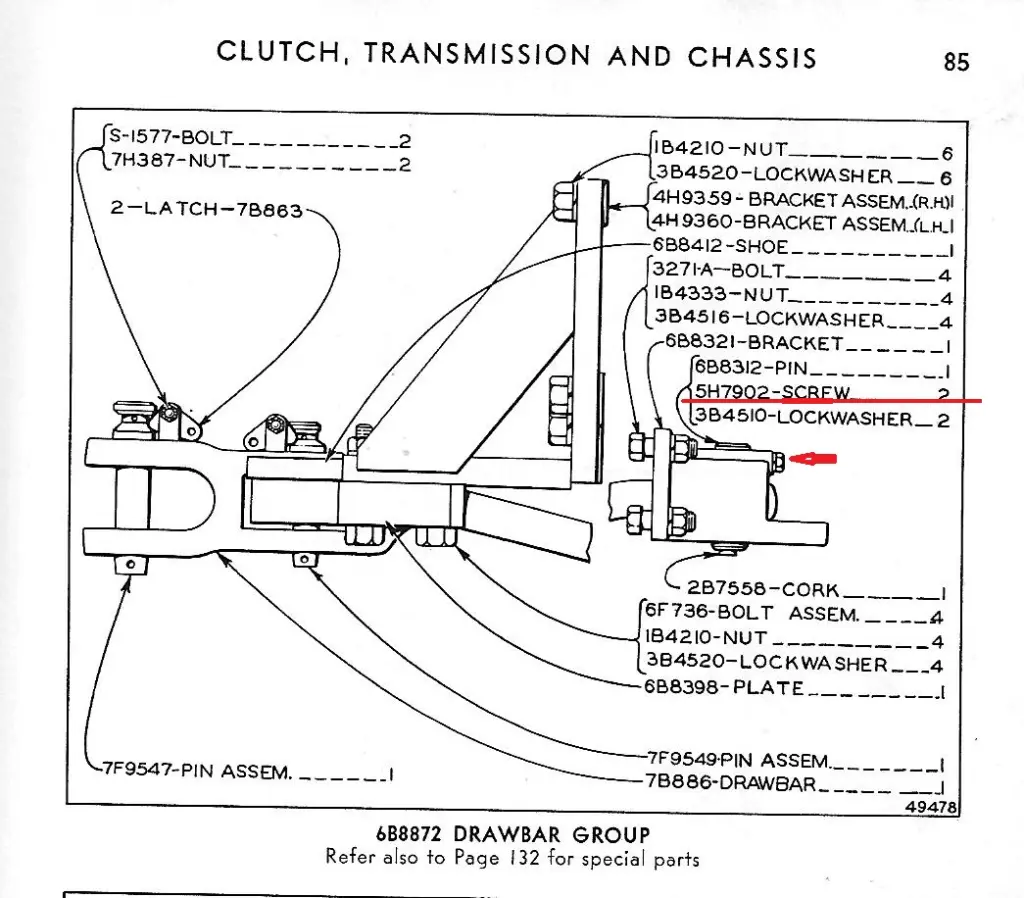

Now to answer your question, the drawbar pin is held in by two screws as shown in the attachment, that come in from the front of the drawbar mounting bracket. The screws have around about 3/4" of thread at the bolt head end and the rest of the screw is simply a straight shank that engages either a groove or two slots near the upper end of the pin--hopefully they are not rusted in or you may have to remove said bracket and drill out the screws.

This was a standard fitment to all sizes of Cat tractors back in the day so I have removed many to fit rippers, winches etc. at the Dealer.

Hope this helps.

Cheers,

Eddie B.

[attachment=64540]Message_1631039090787.jpg[/attachment]Thanks Eddie, yes 17A13356 is my machine and thanks for the insight into their continual update practice. My question is, do i need to drop that skid plate to get to those two bolts? That is a rather daunting challenge given the similar rusted bolt issue. If I need to do that what is the procedure? Hopefully it would pivot down so I don't have to lift the whole thing back into place. I sort of think those two pin retention bolts will be rusted in, they have been in there for a long time. If I have to drop the skid plate only to find they are rusted in then I might as well just leave the skid in place and just start drilling from the back.Any thoughts are appreciated

Joe .

The picture was taken while I was removing the nuts from the studs. Hot wrench,penetrating oil and 6ft bar and they were still very hard. Near tool breaking force.

I wouldn't even try working the drawbar in place. Remove the belly pan then the drawbar, bracket and all . The bracket bolts may need to be torched to get them off but they are replaceable. I've had fair luck getting those pin bolts out after generous soaking in penetrating oil but that is only practical when the unit is out and you can position the drawbar so the penetrating oil can do it's work....along with a healthy impact gun. Do your best to undo the pin bolts as drilling them is a bitch.

Hi Team,

you should be able to lower the rear end of the belly pan down with a jack--leave the front bolts in place but loosened to achieve gap between the pan and the chassis/frame for lowering fully--if the front bolts are too short to lower the pan enough you could use some all thread and nuts or longer bolts in place of the standard front bolts and get more lowering gap.

You could then have enough room to remove the drawbar mounting bolts as OM described, do it out from under the machine if a attempt at first removing the pin retaining bolts fails--you may get lucky.

Cheers,

Eddie B.