Hi Palmer,

seems to me that the pony governor is either stuck by the vertical shaft being seized in the pot metal cover --no bearings, just runs in the pot metal--or if it is free then the gov. weights could be broken off--known to happen.

Carefully remove the pulley cover and see if all is well in there. Be aware that the weight pivot shafts are held in by the cover fit in the pulley and if orientated wrongly can fall out and be lost--be prepared to catch parts or remove the Gov. and do it on the bench. If not check the weights are vertical thus ensuring the pivot pins are horizontal and you should be OK.

The Gov holds about 2 tablespoons full of oil put in via the weight cover end.

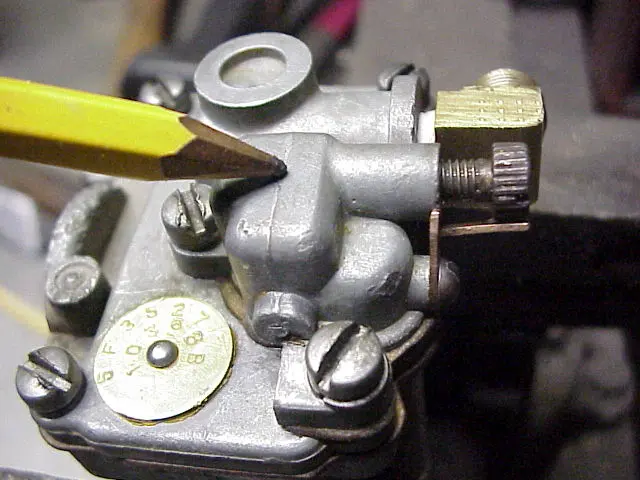

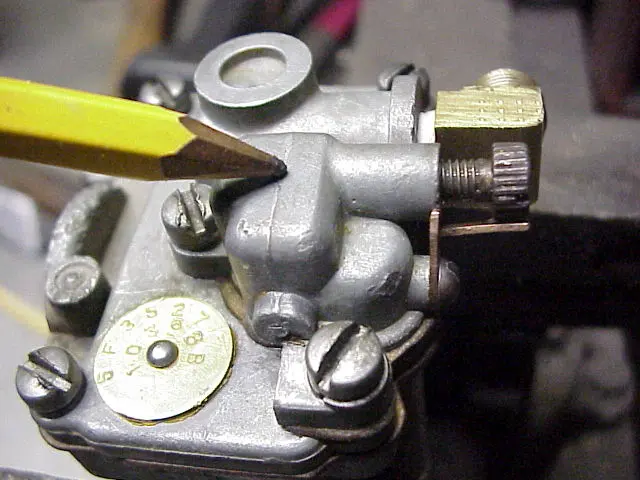

If you are having to run the engine by using at least half choke then the usual thing to happen with the main jet mechanism on later horizontal main jet screw carbs is for the 90 Degree lever, situated in the little cover that holds the Main Jet adjuster screw, is for the screw to be screwed/bottomed in too tightly when feeling for the seated actually full open position, when setting the initial setting of GENTLY bottomed and turn out 1 turn.

Be sure your main jet adj. screw is easy to turn so you can feel for the very subtle bottoming of the screw--screw too hard and the lever bends until it hits the side of the little cover and you then feel the screw tension increase and then stop when bottomed, too late, she's bent.

Check the lever and re-bend to 90# Remember that the lever reverses the screw action and it is IN for Richer, Out for Leaner--be careful to not screw in to hard or you will bend the lever again and make it too lean to run without choke.

The idle adjust is 1/2 turn out from bottomed.

There has been volumes written and pictures posted on this subject here to the point of nausea. Advanced Search function is useful in finding same.

Hope this helps.

Cheers,

Eddie B.

.webp)

.webp)

.webp)

.webp)