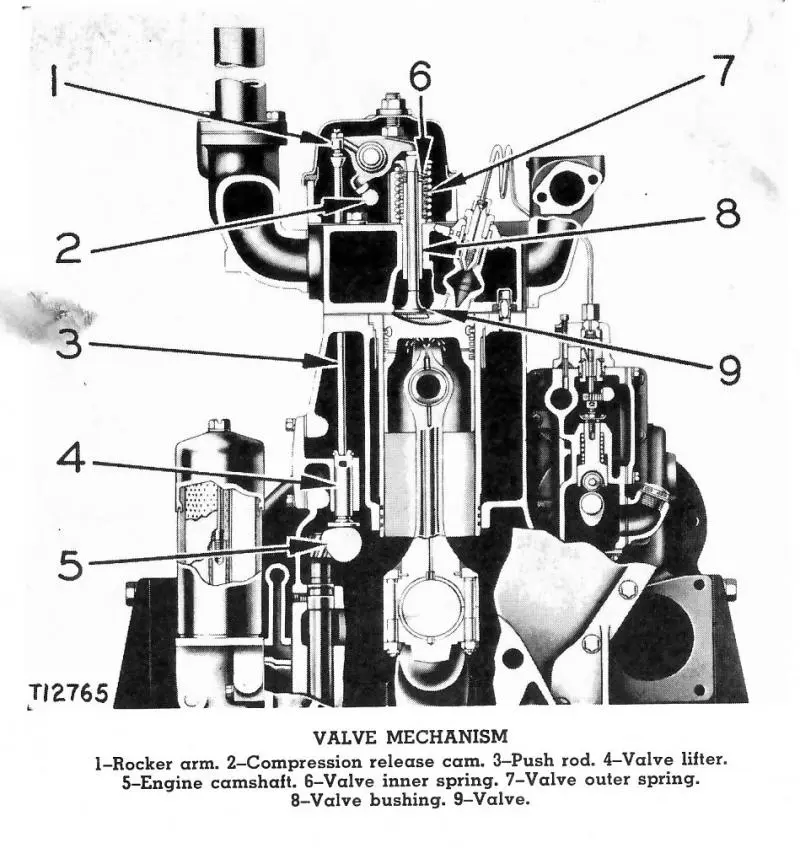

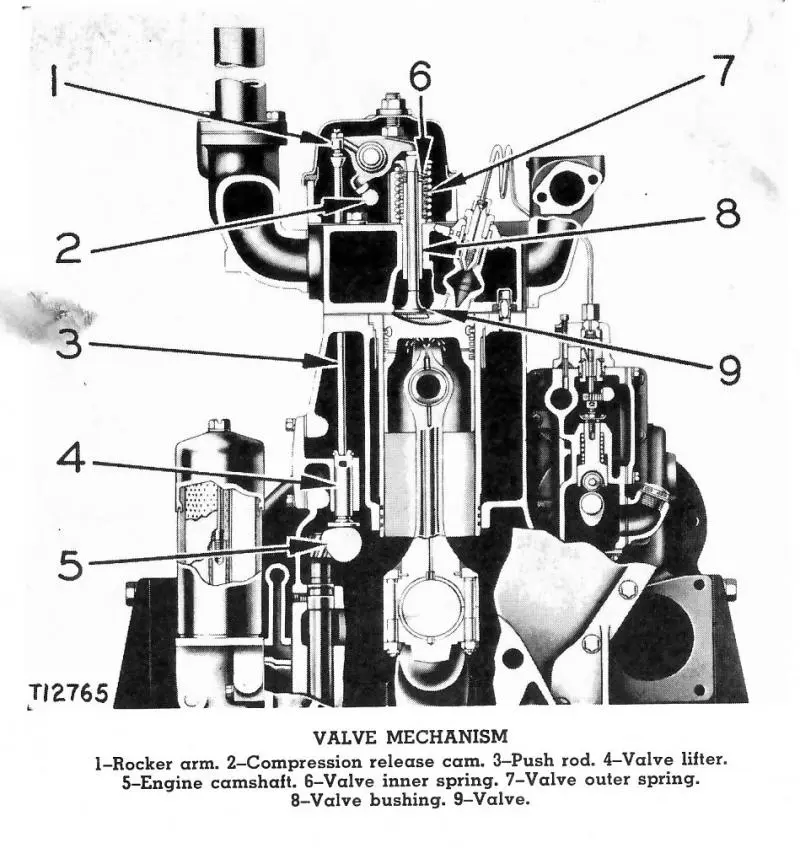

Make sure your pulling the lever out hard enough to release compression and the linkage is intact. With the valve cover off in run position there should be clearance between the cam and rocker. In the start position the cam holds the rocker up and the valve open

Hi Mabc,

there should be about 0.125" clearance between the inlet valve decompression rocker pad and the decompression bar cam with the valve in the closed posion and lever in the run position.

It is not adjustable and comes about when the valve stem length above the head top surface is correct.

If the valve stem length and the rocker pad to valve stem end are as new all is well. If the head has been overhauled and the Factory mesurements not adhered to this problem occurs.

The problem of lack of decompression often happens when valve seat inserts are fitted to the head and the Cat seat dimensions are not adhered to---ie the valves sit too high above the head face---this makes the valve stem artificially short and therefore upsets the decomp. dimension. It also increases compression which is likely OK as long as the valves do not contact the pistons. Conversly pocketed in valves decrease compression and also the decomp. dimension.

See scan below.

About the only fix---as long as the lever and decompression cam are moving to the full decompression position --- is to build up the decompression pads on the inlet rockers to achieve the 0.0125" clearance needed.

Cheers,

Eddie B.