Hello Markds3

I may be wrong as I have never worked on a D2 but if you are only working on the clutches and the bevel gear then you shouldn't need to break the tracks.

Regards

Phil

https://www.acmoc.org/bb/discussion-d72/20795-d2-5u13753-master-pins-please-check-my-understanding?start=0

Hello Markds3

I may be wrong as I have never worked on a D2 but if you are only working on the clutches and the bevel gear then you shouldn't need to break the tracks.

Regards

Phil

you have the pin with the large and small plug, you drive the small plug in and drive right through to drive the large lug out.

Wombat

[quote="Wombat post=241316 userid=4746"]you have the pin with the large and small plug, you drive the small plug in and drive right through to drive the large lug out.

Wombat [/quote]

Thanks Wombat,

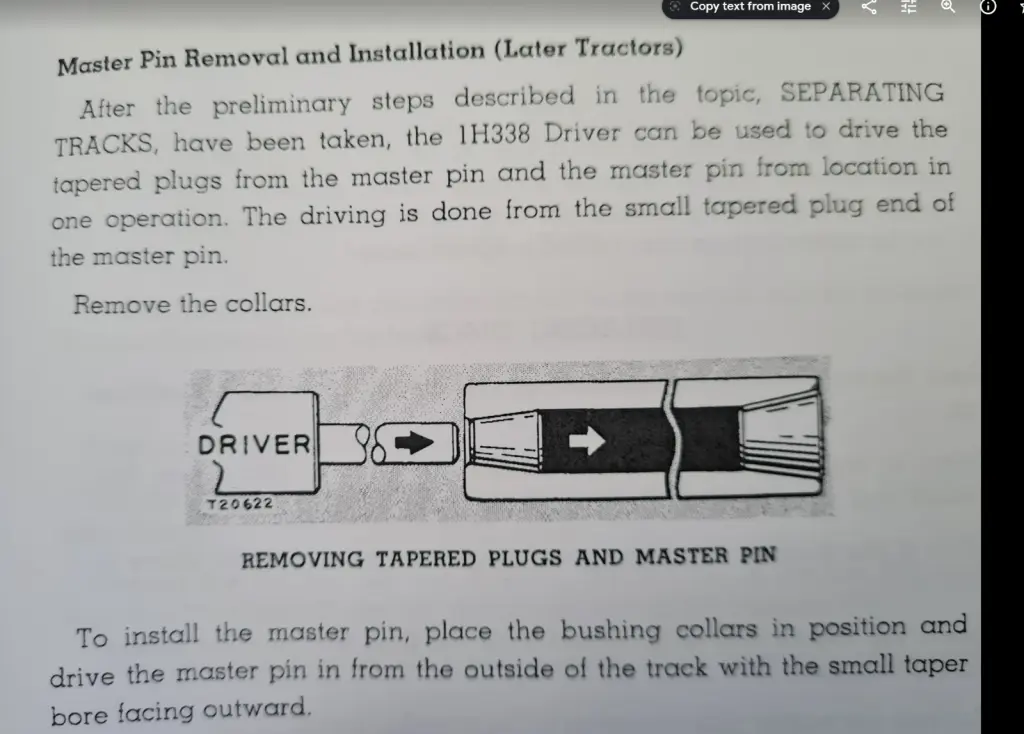

I'm a little stumped as from what I can see from my Servicemen's reference book:

[attachment=69152]Screenshot 2022-10-16 095722.png[/attachment]

I should be able to see the end of the tapered plug from the end of the master pin, at least the smaller plug, i.e. the plug should at least be slightly recessed or proud of the end of the master pin, somewhere where I have indicated with the red circle below, however I can see nothing, even with cleaning up the end of the pin:

[attachment=69154]Screenshot 2022-10-16 100142.png[/attachment]

Thats a late style master pin, they put the recesses in to locate it on the rails. Doesn't look like it was hammered in enough on the one side.

Thanks Rome, so to remove it you just pound on the end until it drifts right through? I've been trying with a brass drift and a sledge hitting it as hard as I can and I can't get it to budge, any suggestions?

[attachment=69155]20221016_133456.jpg[/attachment]

You can try heating the pin boss on each side and maybe put a wood beam and jack to the other side track to support it better. Where you located? I have access to a pin press.

[quote="PhilC post=241314 userid=11059"]Hello Markds3

I may be wrong as I have never worked on a D2 but if you are only working on the clutches and the bevel gear then you shouldn't need to break the tracks.

Regards

Phil[/quote]

The D2 is notoriously difficult compared to the larger tractors (D4 included) as the only way to access the steering clutches is to pull the final drives, and to do that you need to remove the tracks, track frames, pivot shaft and drawbar.