"i reject your reality and substitute my own" - adam savage. i suspect my final words maybe "well shit, that didnt work"

instead of perfection some times we just have to accept practicality

try artu drills they are made for drilling tough material.

is that supposed to come apart though?

They are going to be a nightmare to remove. Even if you had a drill that would drill them keeping the drill on center will be a problem. Looking in the parts manual it shows they are not supposed to be roll pins but solid pins.

"i reject your reality and substitute my own" - adam savage. i suspect my final words maybe "well shit, that didnt work"

instead of perfection some times we just have to accept practicality

a tri flute drill could do it but only if you could get one to drill that kind of steel roll pins are high tensile. and if you could get one in the right size. ive only seen drawings of them.

actually a carbide or ceramic end mill might work and a mill would have the accuracy and allow the clamping of the part if you can get one the right size.

slightly smaller might allow you to collapse it with punch and drift and remove it that way.

you could try welding a peice of round bar into the pin so you can get a slide hammer on to it but do it wrong the part is probably ruined beyond salvage.

Try turning a metal screw in that just turns in easy or a thread tap, and small screw then use a vise grip slide hammer or make something like it, easy does it though, worth a try, may or may not work.

Thanks for all of the suggestions.

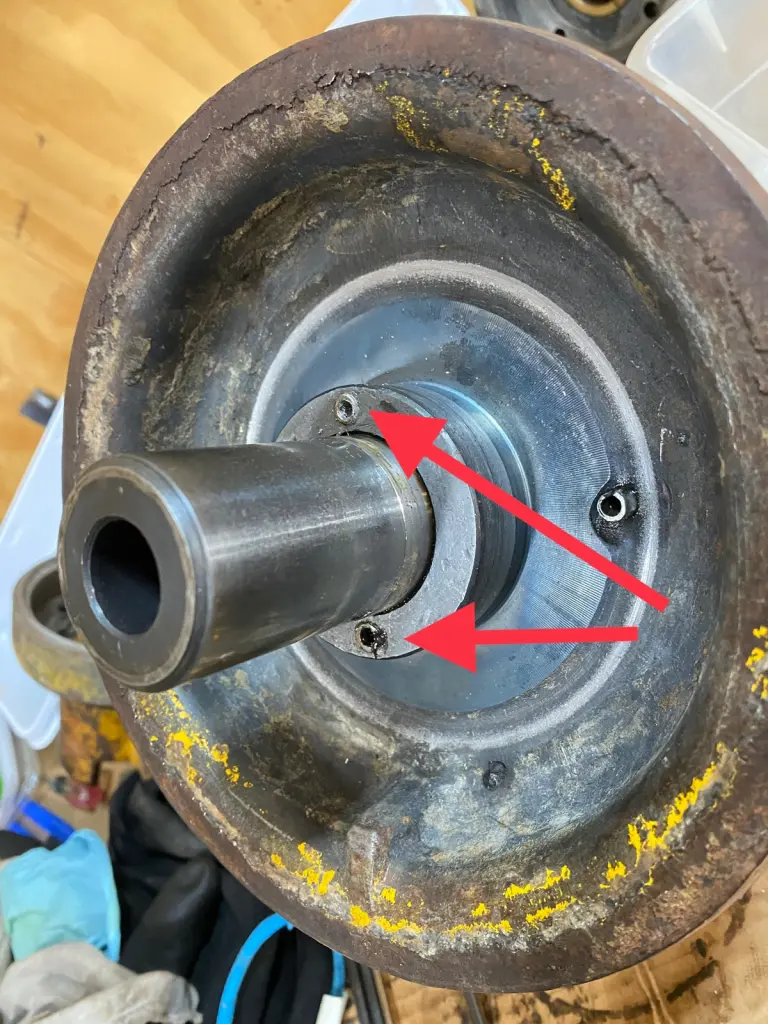

It must be my lucky day - I got all six out without incident!

[attachment=69556]171C41D3-4E0B-4B89-A9F0-032CA26F7DE0.jpeg[/attachment][attachment=69557]75E84726-A72A-436D-8A67-D7CB0506093B.jpeg[/attachment]

Chad

Thanks for all of the suggestions.

It must be my lucky day - I got all six out without incident!

[attachment=69556]171C41D3-4E0B-4B89-A9F0-032CA26F7DE0.jpeg[/attachment][attachment=69557]75E84726-A72A-436D-8A67-D7CB0506093B.jpeg[/attachment]

Chad

Well done! Is that a screw extractor you used on the end of your slide hammer?

Looks like my Harbor Freight slide hammer dent puller!!!! Good job!!!!!