Reply to Ray54:

I may be showing myself as fool saying anything rather than keeping my head down. But I have gotten away with a lip seal at $5 to 10 verses a mechanical seal at several hundred dollars. For all manor of reasons I never got a lot of hours put on any of these pumps. But it always work for a while.

Just a poor farmer making do to get something working cheap.I have to be mechanic as I don't have the funds to higher a real one.

Just dealt with a someone who got new castings for a BeGe from Assassinated Tractor at a goodly sum of money.So all parts I believe are available new,if you are willing to pay.

Just a caution after the repair the pump didn't work,but not the pumps fault as he took it off a D6 and put it on a D4 . The shaft turns in the opposite directions on these 2 models. So all was well when the pieces where put in the right order.

I am a little confused OM on your sentence starting with "The rubber part". My rubber part is most definitely chewed up and does not resemble an o-ring anymore. Is a mechanical seal the same thing as an o-ring?

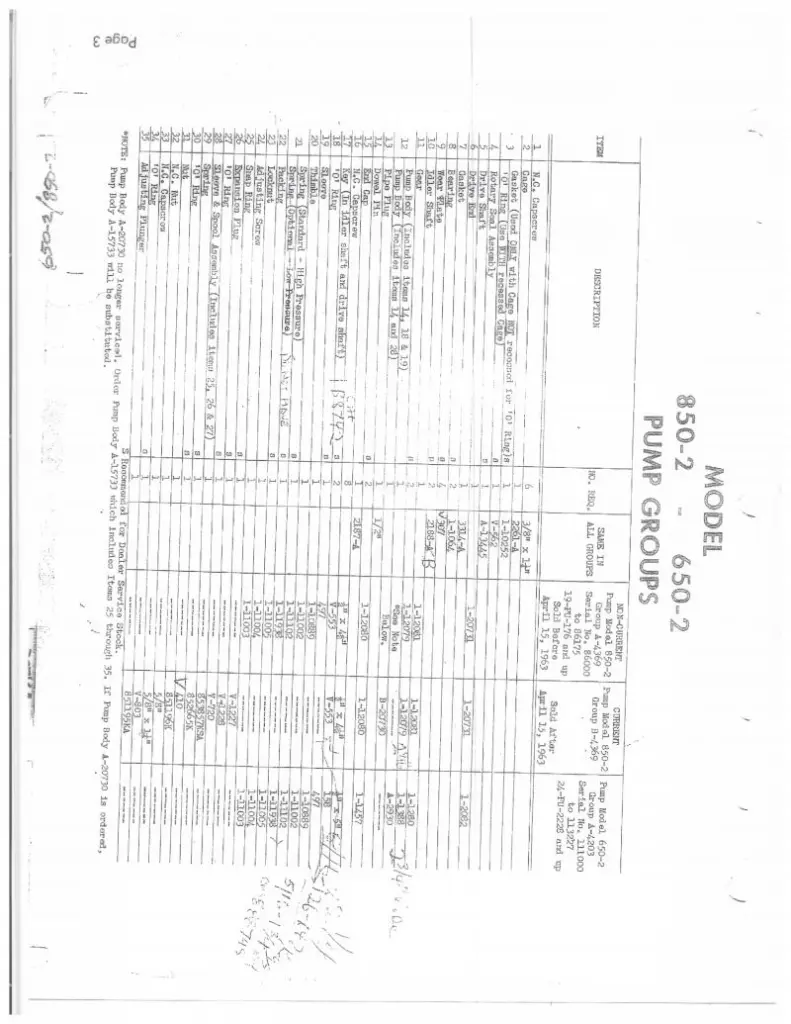

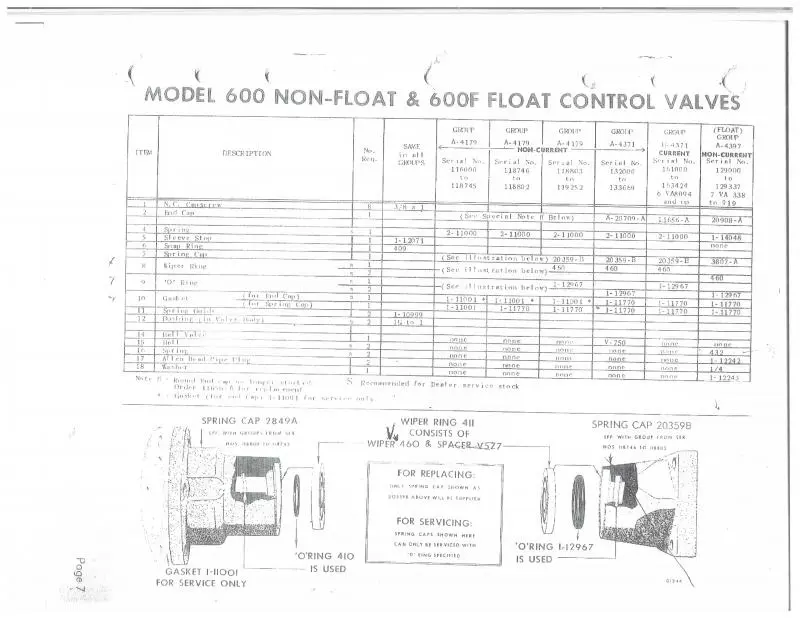

Ray I had that thought that a lip seal would probably work fine, but since I apparently can get the correct parts from AT I will do that. Just the friction ring and brass washer will be pretty cheap. The bronze seal seat, seal ring (cup that holds rubber seal), thrust washer, and spring are still fine. I am like you; I am my own mechanic, but kind of enjoy it. I am needing pump to stay fixed in hot, dusty conditions so this time I will go back with what they suggest and will report back cost when I know.

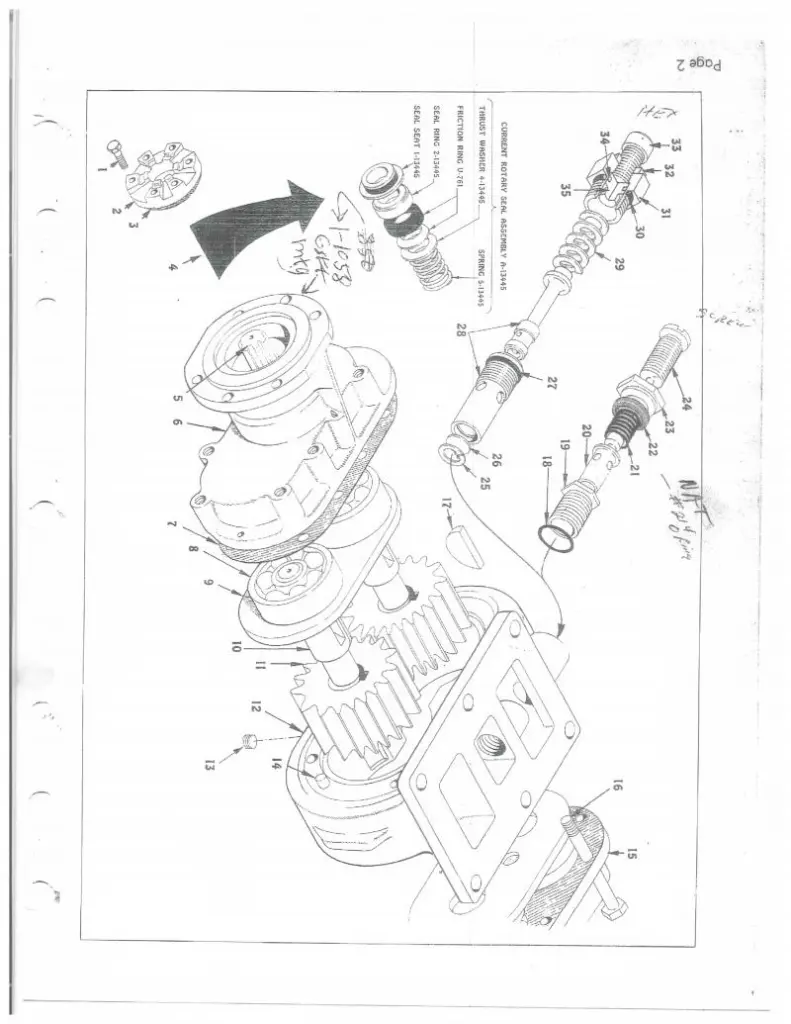

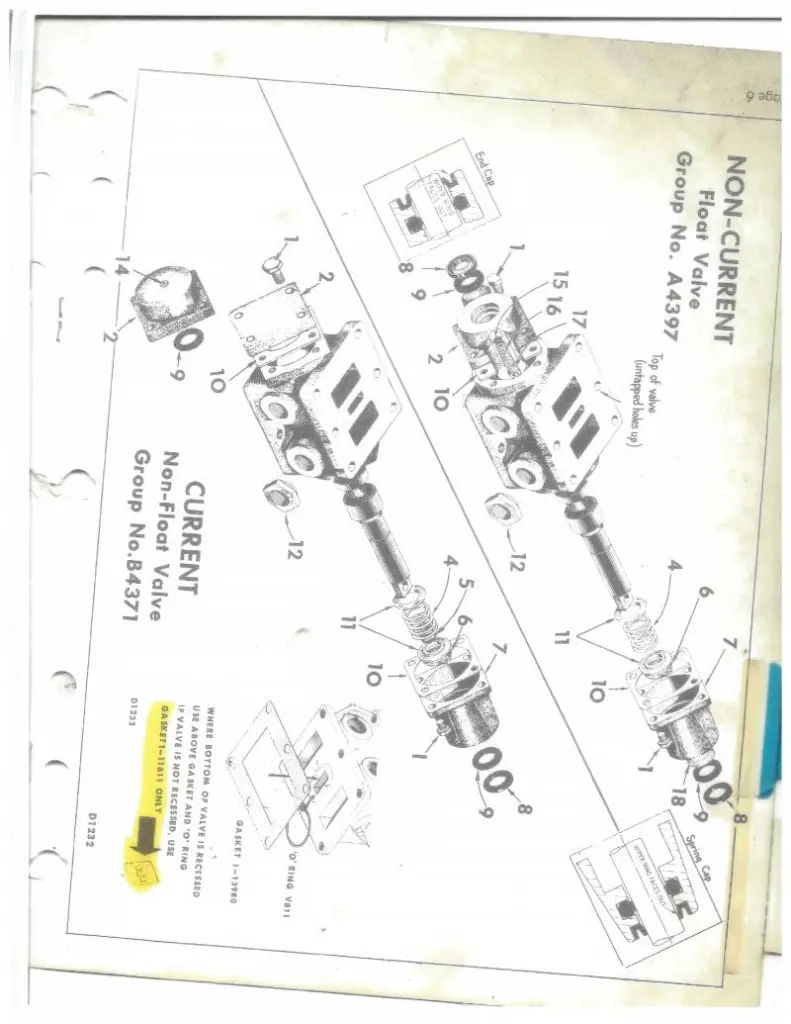

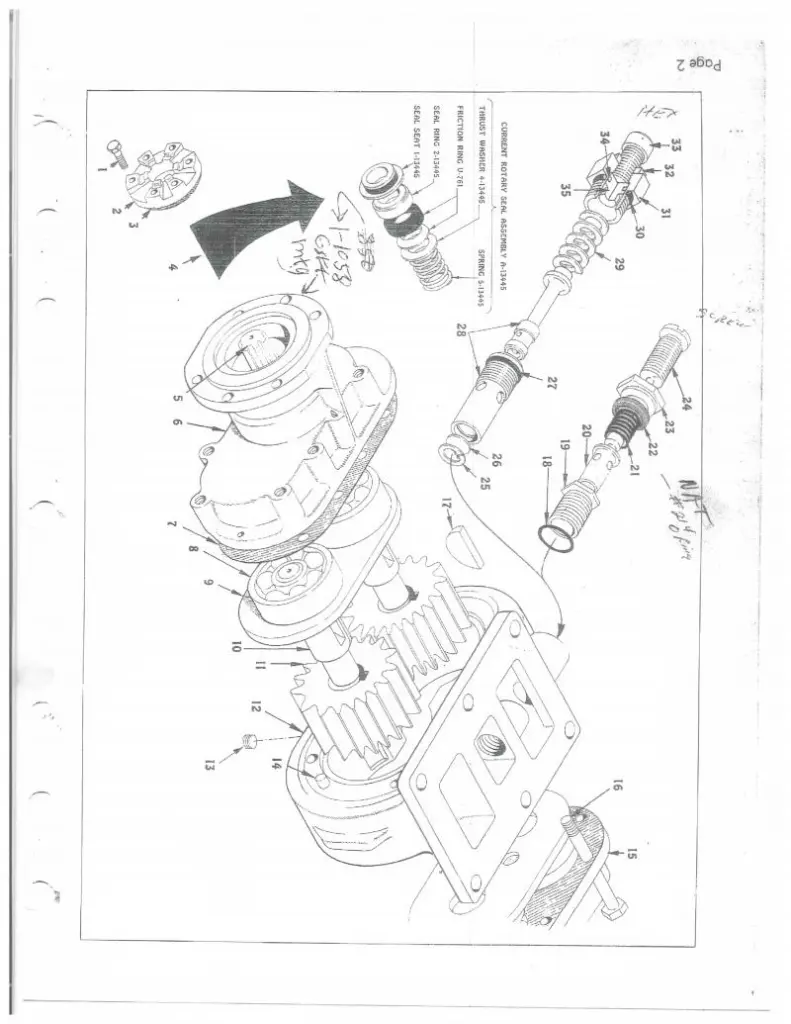

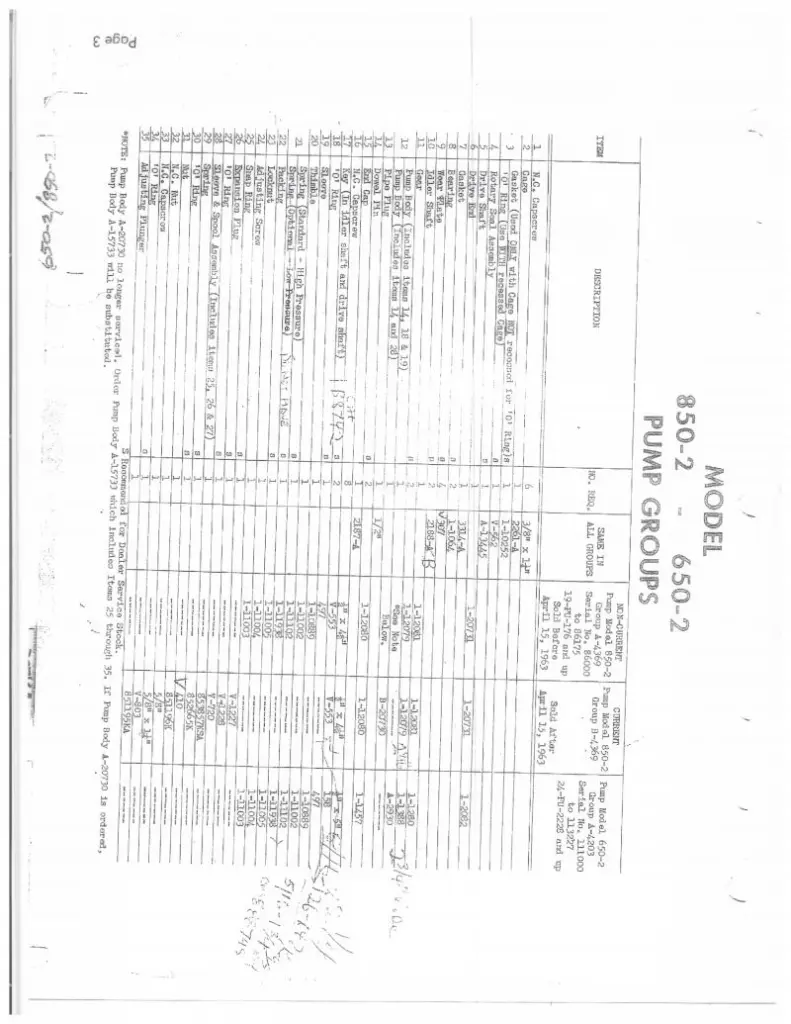

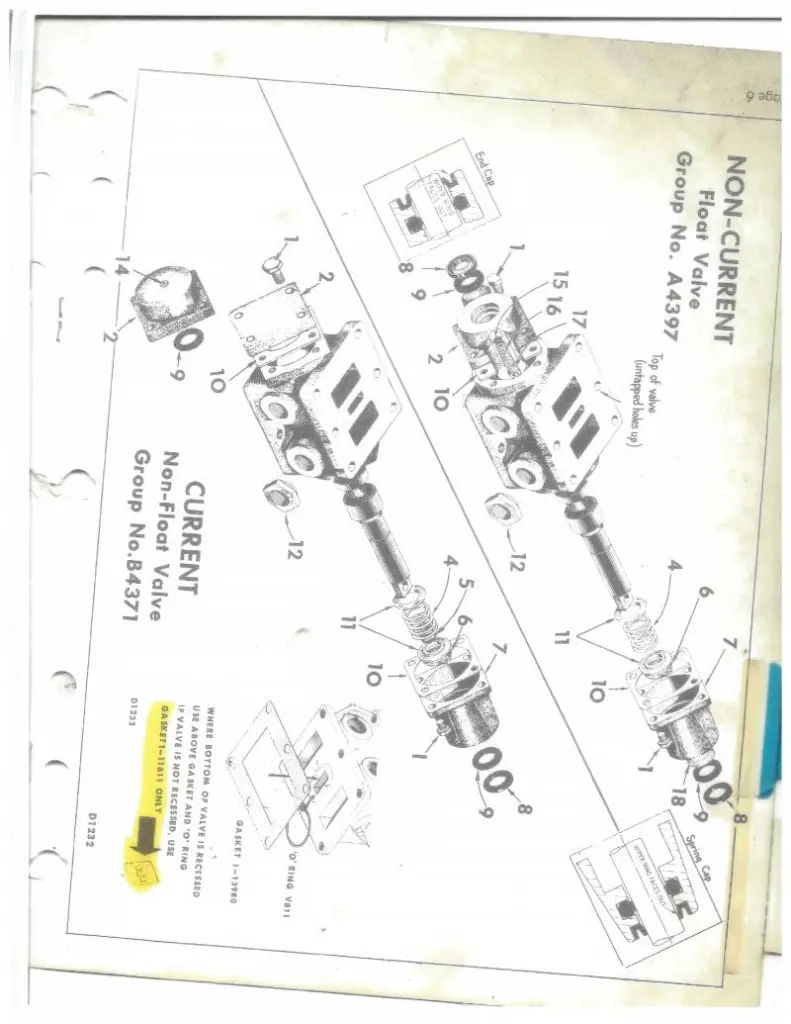

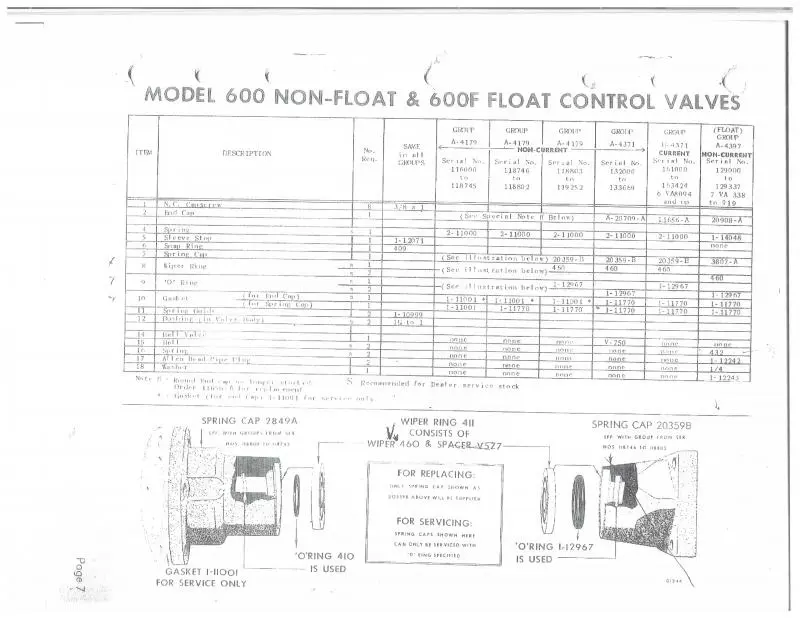

Pete - here are some scans that might be of help to you and other Bege or Bege knock off owners. I apologize in advance for laminating them and hope the scan quality is decent. In one of these the V-761 can be seen with arrow pointing to both the friction ring and the thin brass washer.