Hi,

good news--almost.

As mentioned else where, there is a lever behind the Gov Housing that the control linkage comes to for moving the Gov. control shaft.

There can be debris build up causing lack of travel distance to get to the shut-off position.

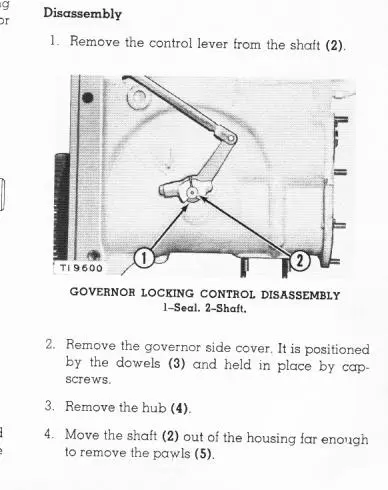

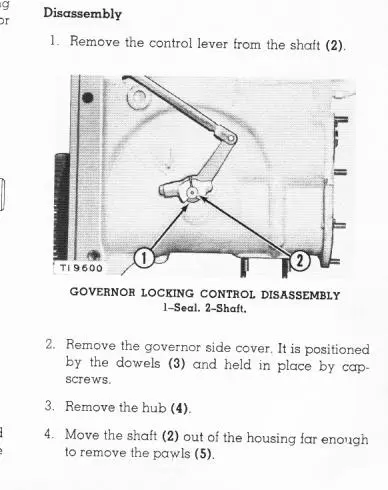

On some units the lever is split with a clamp bolt that can come loose or the lever boss has split and not clamping, see scan below.

On others the bolt just goes thru the shaft and lever to hold it in place. After time the bolt and shaft bolt hole wear and travel is lost. You can recover about half of the lost travel here by fitting a new unworn bolt.

Suggest check for worn linkages that cause loss of travel and hence the inability to get the travel needed to achieve shut-off.

Hope this helps.

Cheers,

Eddie B.

Never thought of checking for lost motion at the shaft:doh: will do today. Also gives me cause to wonder if it was installed correctly when the motor was rebuilt. I have that service manual and don't see any great explanation on how that should be adjusted. Guess it should be obvious that it needs to be fully shut past detent by time the bell crank attached to the governor control lever is at its maximum forward rotation point. Furthest point from center of rotation of the governor control rotating center. Thanks for pointing me in the right direction!

Could un-pin the linkage and push the throttle past shutdown detent, then push rod on bell crank to see how much difference there is in length due to worn pins and bushings. By changing out worn pins, you may even pick up a few top end rpm, cause if the linkage is sloppy enough to not push it to shut off, it will be sloppy enough to not pull it to wide open position!