This should cover it....

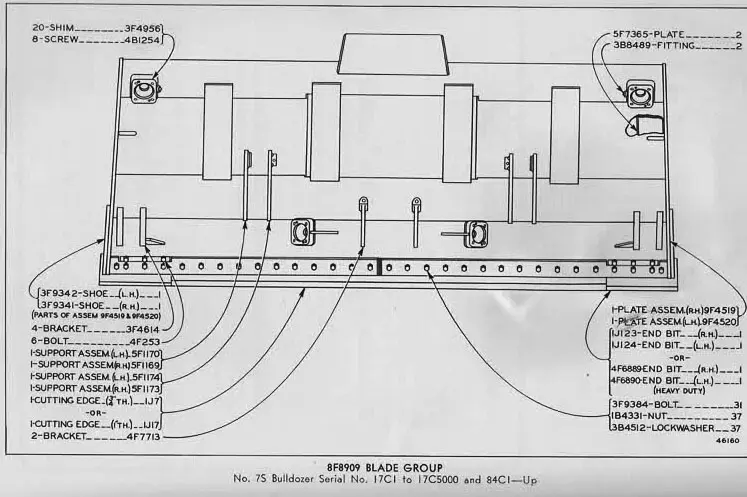

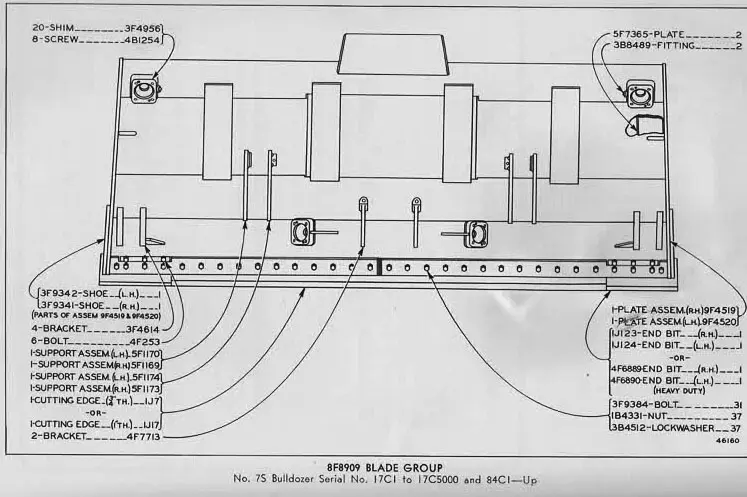

I want to thank Old Magnet for the parts diagram for the 7S dozer blade. I will need new cutting edges in the near future and have not been able to find parts numbers. The numbers in the parts diagram for the end bits work fine and many seem available. The center edge number is a bit confusing and I have tried different prefixes and the likes to no avail. Does anyone have correct part number for center cutting edge ?

Add "zeros" to standardize parts numbers, 1J0007 and 1J0017.

Current numbers are 4T2954 for the (3/4") and 4T2864 for the (1")

General Duty end bit numbers are now 3J2463 (R) and 3J2463 (L) These are 1.12" thick.

Old Magnet, Thanks for the bolts sizes--I wanted to wait until I put the edge & end bits one before getting back in touch and I still haven't gotten to installing them.

I finally got the main engine valves set and started the tractor up to go out side and hooked onto the dozer today. Now my 25 CCU won't adjust right and I can't run it. I wrapped the excess cable around the tractor about 30 times and used Dads old 850 Case loader to pick the blade up and chain it so I could get back in the shop before anyone saw me. While hooking the dozer up and partially installing the cable I notice a excessive amount of diesel draining from the injector pump. I plan on pulling the injector pumps off a parts tractor and I need to know how to pick the best 4 of the 8 pumps I will have to choose from. Any ideas on this? Also I have a question of the shutting off the tractor and also starting it--Does a 17a 3130 have a fuel shut of that is engaged by pushing the throttle forward? I ask this because

when starting the tractor and putting it from start to run fuel is coming out of the pump.(I found this out when bleeding the injector lines) I would think there wouldn't be any fuel to the engine until the throttle is moved down some to release the fuel shutoff . I hope some one has a few thoughts on this. Thanks, Lex

Old Magnet, Thanks for the bolts sizes--I wanted to wait until I put the edge & end bits one before getting back in touch and I still haven't gotten to installing them.

I finally got the main engine valves set and started the tractor up to go out side and hooked onto the dozer today. Now my 25 CCU won't adjust right and I can't run it. I wrapped the excess cable around the tractor about 30 times and used Dads old 850 Case loader to pick the blade up and chain it so I could get back in the shop before anyone saw me. While hooking the dozer up and partially installing the cable I notice a excessive amount of diesel draining from the injector pump. I plan on pulling the injector pumps off a parts tractor and I need to know how to pick the best 4 of the 8 pumps I will have to choose from. Any ideas on this? Also I have a question of the shutting off the tractor and also starting it--Does a 17a 3130 have a fuel shut of that is engaged by pushing the throttle forward? I ask this because

when starting the tractor and putting it from start to run fuel is coming out of the pump.(I found this out when bleeding the injector lines) I would think there wouldn't be any fuel to the engine until the throttle is moved down some to release the fuel shutoff . I hope some one has a few thoughts on this. Thanks, Lex

http://www.tpub.com/engine1/en1-58.htm

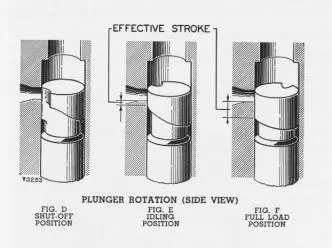

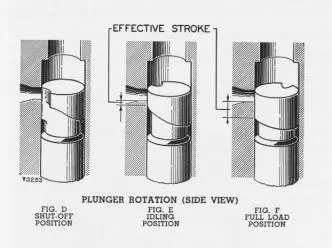

Link shows a good plunger and scoring in the helix area of the plunger--this area has to seal the high pressure injection pressure fuel. Dirty fuel at worst causes the scoring shown but usually the area can have a grey matt finish from small particles sand blasting the area. The spill port inside the barrel with have similar shading as per the finish on the respective plungers.

Some grey matt is OK but scoring is not good for even running at low idle/loads.

The length of helix closed of at thee port determines the amount of fuel injected--mixing worn pumps from two engines can give rise to uneven running due to the leakage rates.

Pix of worn pumps are a bit hard to find online and as yet this is the best I found--nothing in my Literature from Cat but it does exist.

Scan is of how the helix controls the volume of fuel delivered, when running light loads only a small area of the helix is working and so results in the most wear from dirt particles in the fuel.

A jewelers Loupe --small magnifying glass held in the eye socket area-- is what we used at The Dealer to inspect the high wear areas mentioned--later on we got a microscope and that was scary to see dirt abrasion and erosion pitting effects on these hard working parts.

A true guide for pump serviceability is to test them on an injection pump test bench for delivery volumes at given rack settings as compared to known test results of new components--charts from Cat test sheets give the variance allowed.

Hope this helps.

Cheers,

Eddie B.

to All,Thanks for the help on this fuel problem. I have discovered (I hope) the last damage to this cat from the tornado. The injection pump had a small hole knocked in it and camshaft area was full of water. the shaft is ruined so i stole the injector pump off the parts tractor. I am going down the rabbit hole and putting in new bushings, replacing the best lifters yokes, etc. I want to set the lifters and need " Tools 5H9977 and 6H3051--Cat doesn't rent these tools anymore, so how do I make them or what can I use to replace them so I can adjust these lifters? Old Magnet I still don't have the cutting edge on yet--but i do have it on the floor and am tripping on it so it is closer to getting on. Its been cold here in Kansas so most of my time is working in the house. Thanks

Not familiar with the 17a or pump, BUT, on the pump lifter adjust on my 318 in a cat 8t/12 it called for some whiz bang tool.7f4581 and 7f4582, which adjust the lifter height from the top. I used a 6 inch cresent wrench and a 9/16 to adjust the lifter height from the side cover side.

Hi Team,

as oldbeek pointed out, ordinary mechanics toolbox open end wrench tools will do the job just fine--no need for Cat specialized tooling for this.

Lifter settings can be measured and set with a Depth Micrometer or a vernier caliper will do instead of the dial indicator set up later Service Literature shows.

You just need to be fastidious and triple check your adjusted measurements.

Once adjusted a set of 3116 unit injectors with a vernier in the field.

Also at one time, for a Mate, used a vernier caliper to set up a 4 stroke GM V8 Diesel that a local GM Dealer made worse every time they touched it.

Cheers,

Eddie B.