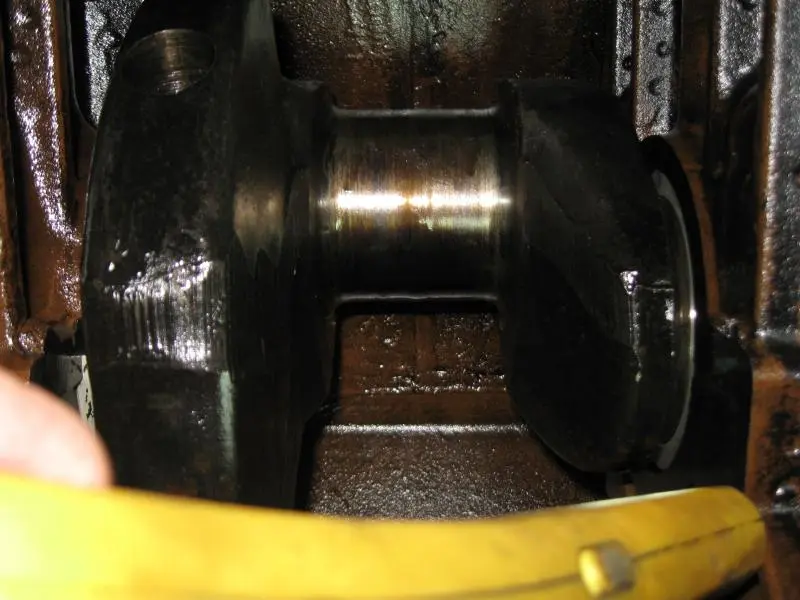

Localized like that I'd suspect loss of oil supply to that rod journal and cylinder. Look for a clogged oil passage in the crankshaft or a problem with the adjacent main bearing journal that would cause loss of oil pressure to that cylinder.

I have run across the piston hitting the head problem in a race car. Bearings were stacked both on top side and that caused piston to move further up the bore by the thickness of the bearing. Caused by a momentary loss of oil pressure.

Hey D8Joe,

I will PM you, I know of a 14-a being scrapped.-glen

Look for the big end failure cause, forget the piston kissing the head, its just a result of the bearing faiure and happens between exuhaust and induction strokes,

Has this engine been operated in any unusual operation lately , like steep grades with low crankcase oil or severe lugging ,or high adnormal heat conditions ?

My BIL was running it when this happened. He was cutting in a ditch behind his house so did have the dozer at a good angle. He said the temp gauge never got hot and it always had oil pressure. Does anyone have a good place to price out

pistons and sleeves? How much would it cost to get a crank this size fixed?

The way that piston is scored ,it looks like the problem started up top ,like a piston seizure ,and then bearing failure.

I would find a good local machine shop ,have them look at that crank ,and get some options what can be done with it . the one rod journal maybe be welded up and turned down if the other's are still in good shape. I would have to check the book ,but I think .030 and .050 oversize bearnings were serviced by Cat

A local Cat dealer may still have a rebuilt crank in stock

Ther's a lot of d-342 engines out there still

Finding parts is the least of your problems. Need to find root cause. I suspect that is not the only bearing problem. Need to check the adjacent main bearing where the oil passage comes from that feeds the rod bearing.

Old Magnet you are right on about finding a cause before tossing new parts at the motor. The crankshaft is chewed up with deep grooves and the motor should get a set of pistons and sleeves. To diagnose the problem this motor will have to be taken out and torn down. I would like to get an idea of the cost before taking the motor out. If the cost of rebuilding this motor is too great then I may have to look for a used motor. I would like to know what the cost will be to go rebuilt or used just to weigh my options. I would hate to tear this motor down and have the parts scattered across the shop for months.

The piston part number is 4m 9110 and the bearing part number is 2m 6499. Is there a couple of good places to call to price out parts for this motor? I have googled the numbers and have not come up with much.

Thanks all for the advise. Joe