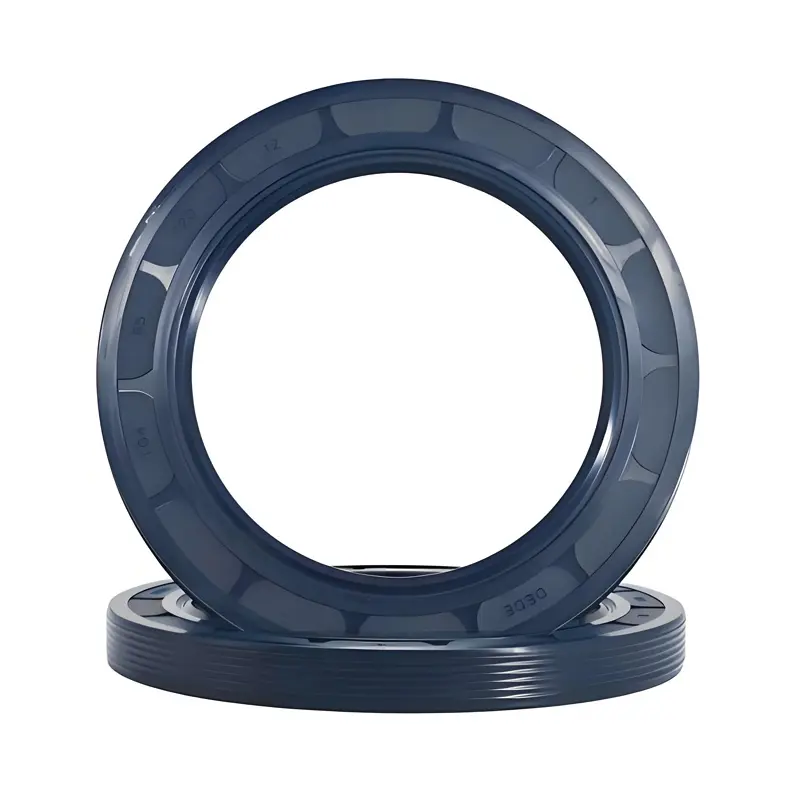

TG oil seals are essential components in dynamic sealing systems, particularly where shafts rotate at high speed under moderate to high pressure. Known for their dual-lip configuration, TG oil seals are designed to provide both primary sealing and enhanced protection against external contaminants, making them ideal for harsh operating environments.

Structure:

The TG oil seal typically features a double-lip structure — the main lip seals the fluid or lubricant inside the system, while the secondary (dust) lip prevents external contaminants such as dirt, dust, or moisture from entering. This design is often reinforced with a metal case or skeleton for added rigidity and stability. In many applications, the sealing lips are supported by a garter spring to maintain consistent radial force against the shaft, even under thermal expansion or wear.

Applications:

TG oil seals are widely used in heavy-duty machinery, gearboxes, agricultural equipment, construction vehicles, and industrial pumps. Their robust construction makes them suitable for applications involving grease-lubricated or oil-lubricated systems with frequent exposure to debris or vibration. They are also commonly found in off-road and marine equipment where durability under extreme conditions is critical.

Materials:

TG seals are manufactured from a range of elastomers, depending on the working environment:

Nitrile Rubber (NBR): Common for general-purpose use, offering good oil and abrasion resistance.

Fluorocarbon Rubber (FKM): Suitable for high temperatures and aggressive fluids.

Silicone Rubber (VMQ): Used in specific cases requiring excellent flexibility at low temperatures.

The reinforcement parts are usually made from carbon steel or stainless steel, while the spring is often carbon steel or stainless, depending on corrosion risk.

Key Characteristics:

Enhanced Sealing Performance: The dual-lip design ensures a tight barrier against both fluid leakage and environmental contamination.

Long Service Life: With proper material selection, TG seals maintain performance under pressure, heat, and friction.

Versatile Fit: Compatible with shafts subject to axial and radial loads.

Excellent Contaminant Resistance: Ideal for outdoor and high-dust environments.

In summary, TG oil seals combine a thoughtful structural design with reliable material options to meet the demands of high-performance mechanical systems. Their durability, dual-protection design, and compatibility with various lubricants make them a preferred choice in industrial and automotive applications where sealing integrity is non-negotiable.

Oil seals, sealants, rubber seals manufacturers, our website: www.dedeseal.com