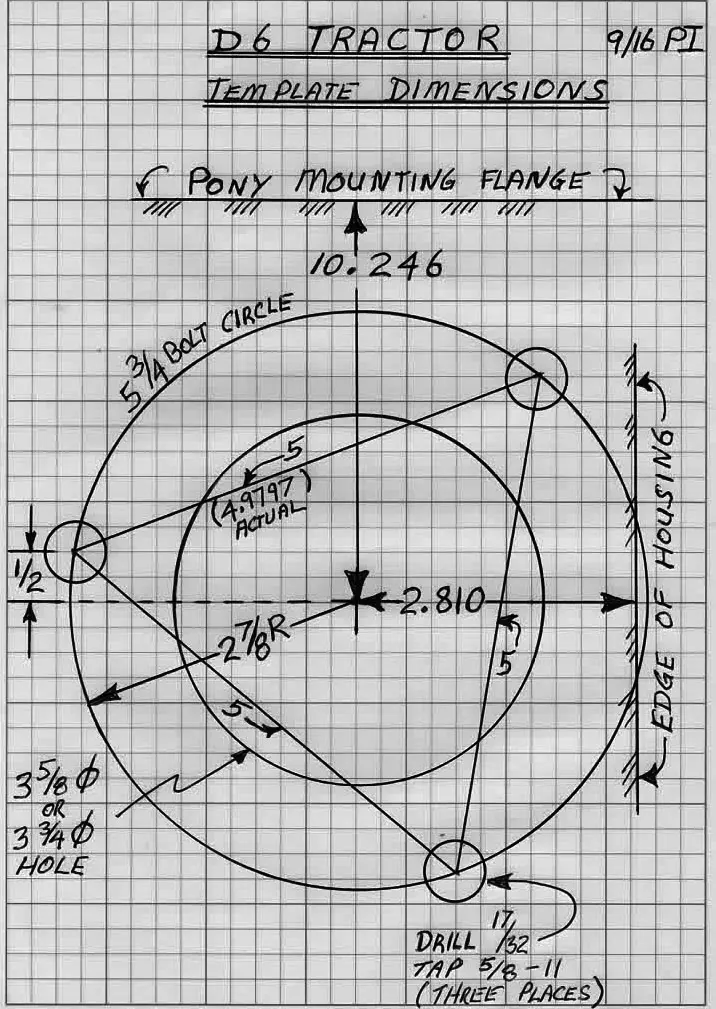

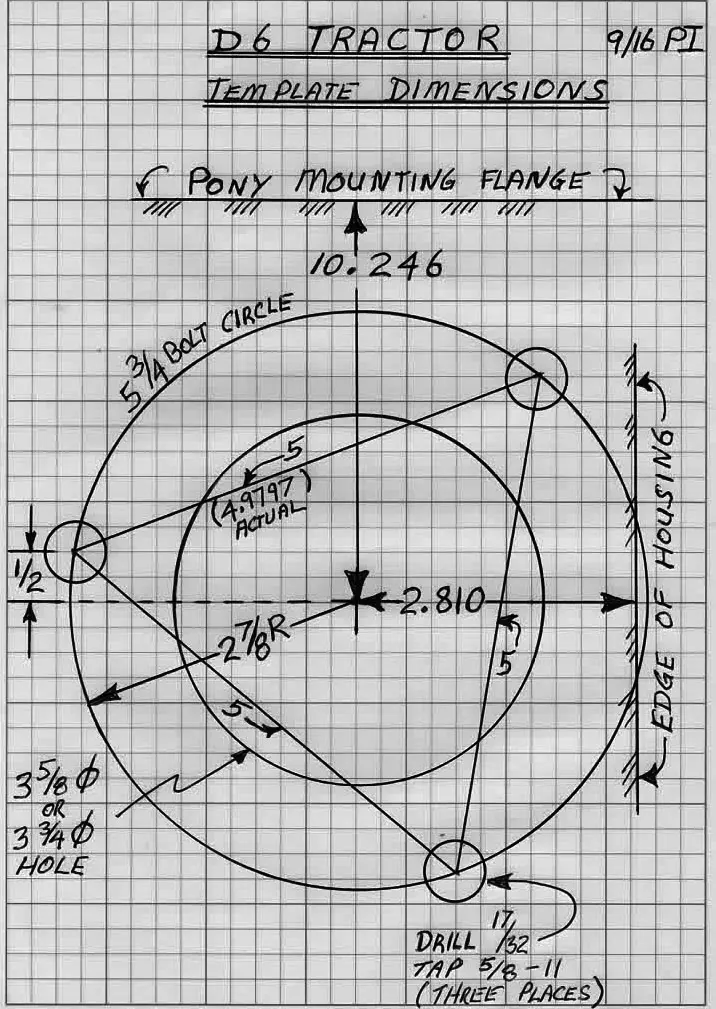

You will need to bore and tap the flywheel housing for the starter. Use this template except the vertical pony flange to center is 10.3125" and the horizontal to center is 3.4825" for the 8T grader.

Factory hole would be 3-5/8" you can bore to 3-3/4" if you need some wiggle room.

[attachment=62925]D6 Template Dimensions (4-16).jpg[/attachment]

Thank you,

Where can I find a starter or parts grader?

Thanks

Paul

Where are you located? Are you looking to run 12v or 24v?

Send me a PM when your ready for a starter.

Old Magnet, Is your layout for boring the flywheel housing above (10.3125 vertical and 3.4825 horizontal) the same for a 7T grader(7T2466 1947 Model, I think) with the 4600 motor? I am using the motor out of a 5R dozer in this grader since the one in it is locked up. Previous owner ran it out of oil on a hill and locked up the motor. Going to change the flywheel housing, oil pan, oil pump, flywheel, head, injection pump and injectors from the grader motor, but since I will have the flywheel housing off it would be a good time to set it on the mill and bore it for a starter. Thanks bboaz

Sorry, can't answer that. I have not dealt with a 7T grader conversion.