Hi Team,

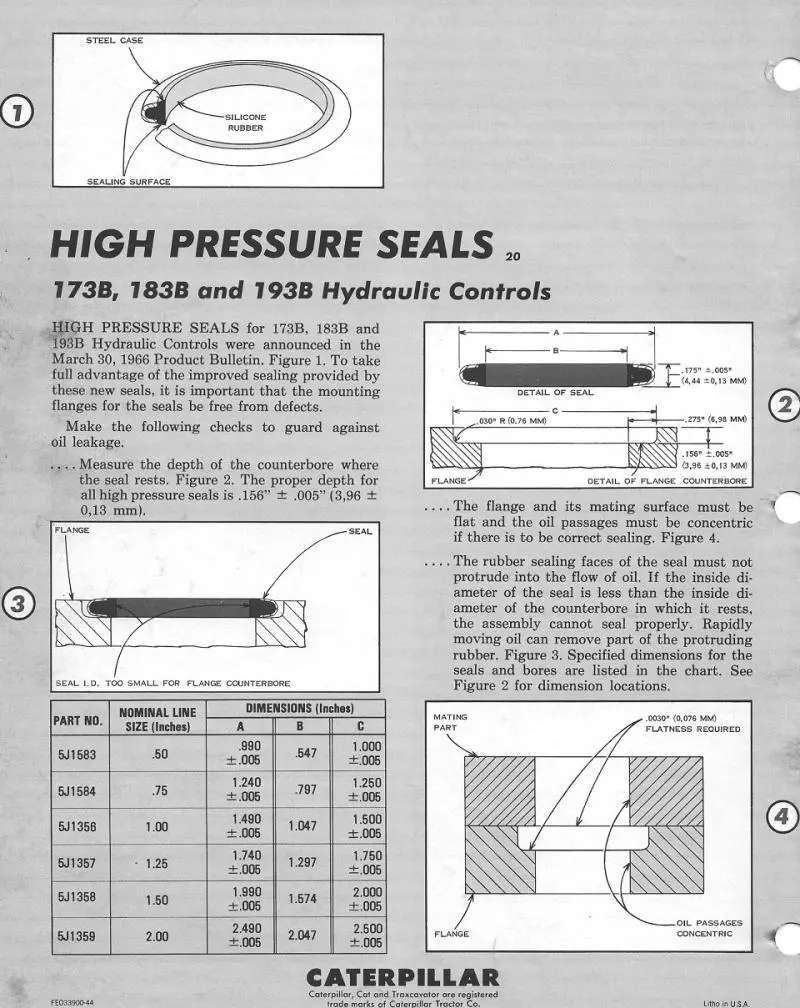

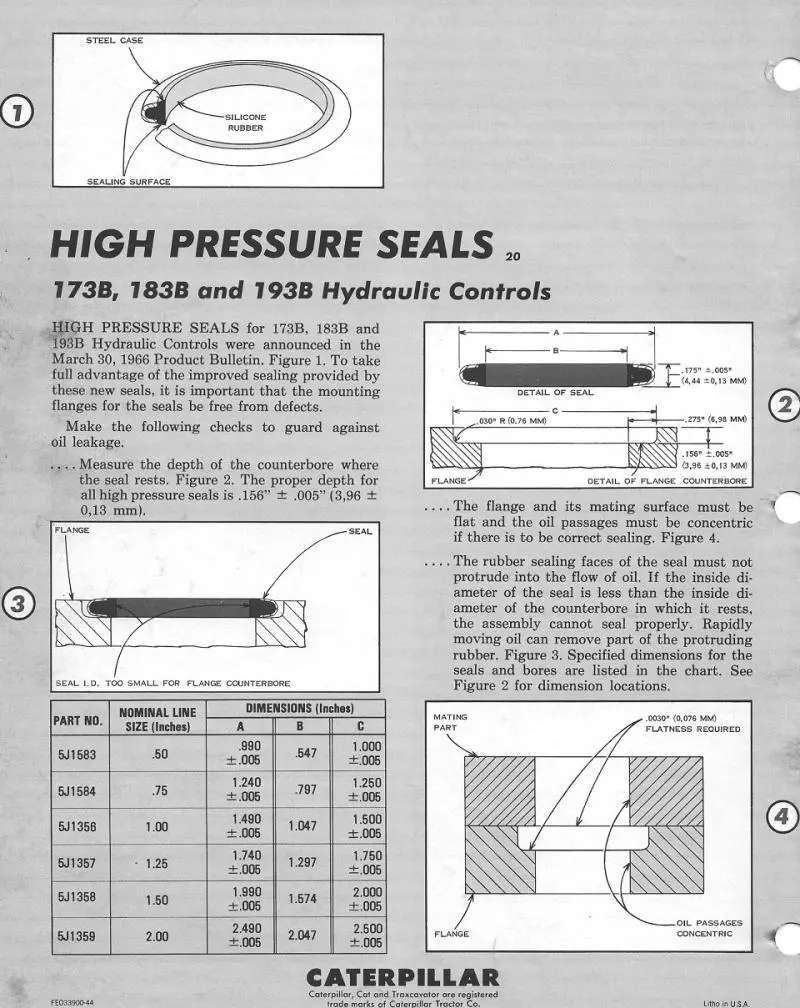

Service Magazine article, June 21-1966, on High Pressure Steel Cased seals used for a short time and I believe are now replaced by D Rings--

The D rings used in the open inside edged groove of suction lines meant to use the steel backs do not work well with negative pressures, so if you come across a steel case seal baby it as you will likely have no replacement other than machining a steel ring to support the inner Face/edge of the D ring so it cannot be drawn into a suction line or Hyd. system that could now have negative pressure in it since cooling over nite.

This can occur especially after removing the sealed system's filler cap when hot/warm.

Cheers,

Eddie B.

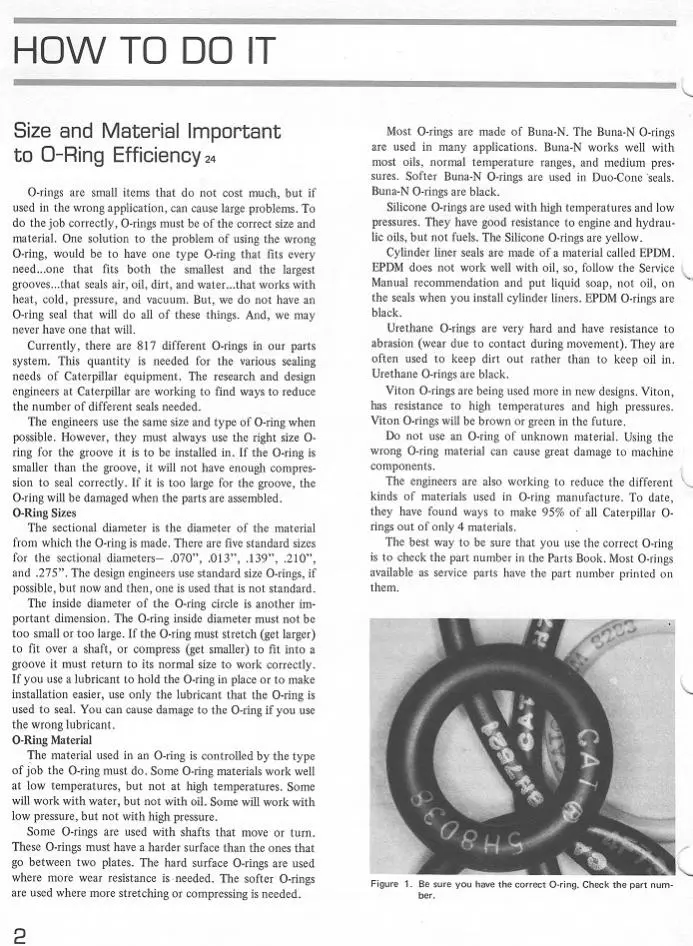

Great timing, Eddie, doing the fuel tower seal on my injection pump on my D4. Any thoughts on using a Viton seal here? I note the CAT seal is nitrile and thought maybe a Viton one would last longer? Part no. 8B-4967 or a dash 318 standard size so easy to source in diff material.

Regards,

Tony

Cats Forever

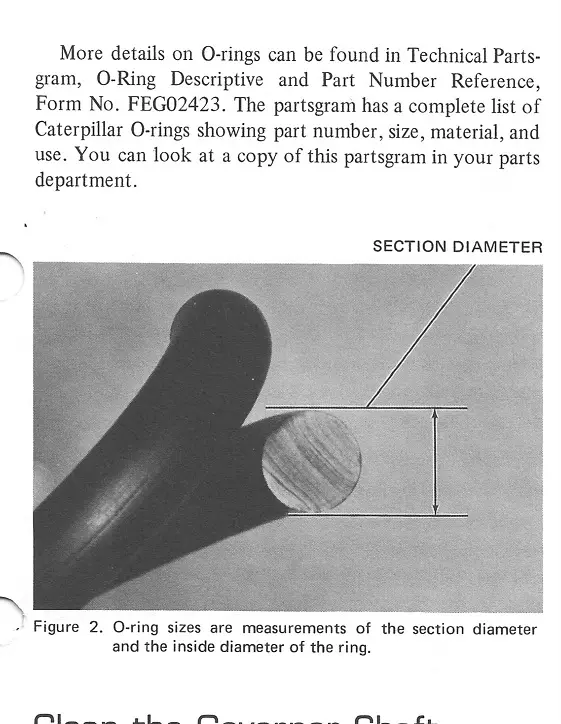

Good articles and "stuff" about working with old "O" rings in the past.

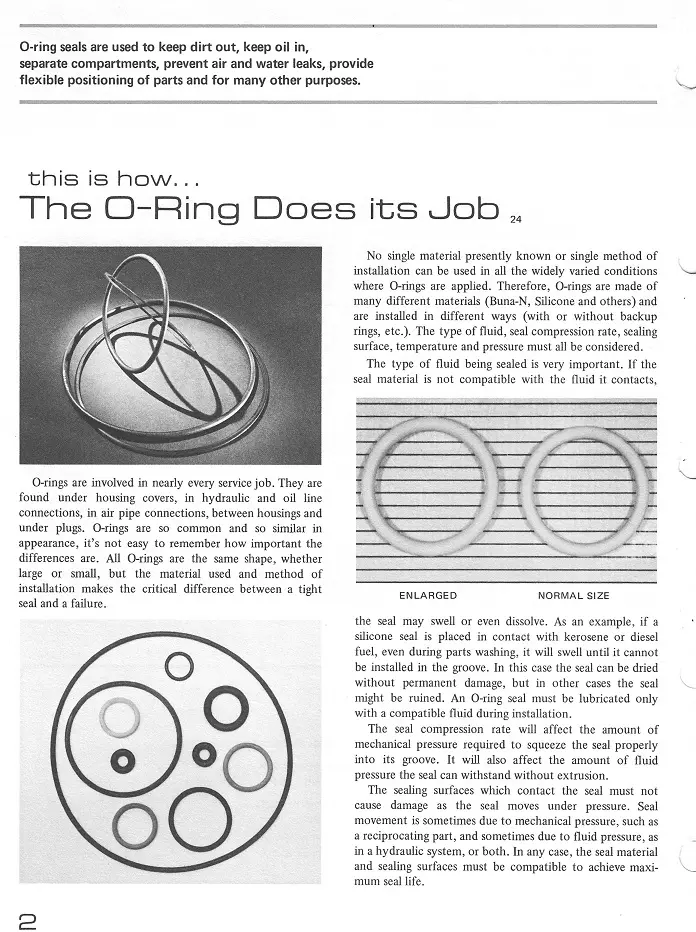

Back in the good old days there were not so many chemicals to be concerned about when choosing an "O" ring or seal material. Nowadays there are so many additives in the various oils and fluids that it is important to know the chemical composition of the oil or fluid that will be in contact with the seal. Here is a typical seal and material compatibility chart for various seals and materials.

https://www.marcorubber.com/o-ring-chemical-compatibility-chart.htm

Orscheln Farm and Home sold a lot of tractor transmission/hydraulic fluid that was supposedly compatible with John Deere and other manufacturers. They are now in the process of settling a multi-million dollar lawsuit as the Orscheln product did not meet the John Deere and other specifications as advertised. One of the Orscheln additives was devastating on pump seals resulting in many failed pumps in John Deere tractors. (Unfortunately I have one that I used the Orscheln fluid) Of course being in farming there are a multitude of chemicals used in various combination for weed and pest control so knowing the chemical composition of the chemical is of vital importance in getting the proper seal. Surprising how some "O" rings look identical but one will turn to mush when exposed to certain chemicals.