I have the retaining pin which goes near the ferrule. Where is the wedge installed?

You need the proper size swedged ferrule...1.63" diameter/42mm and 2" long/51mm.

Yep, I believe it is the #B4, 1.63x2.00.

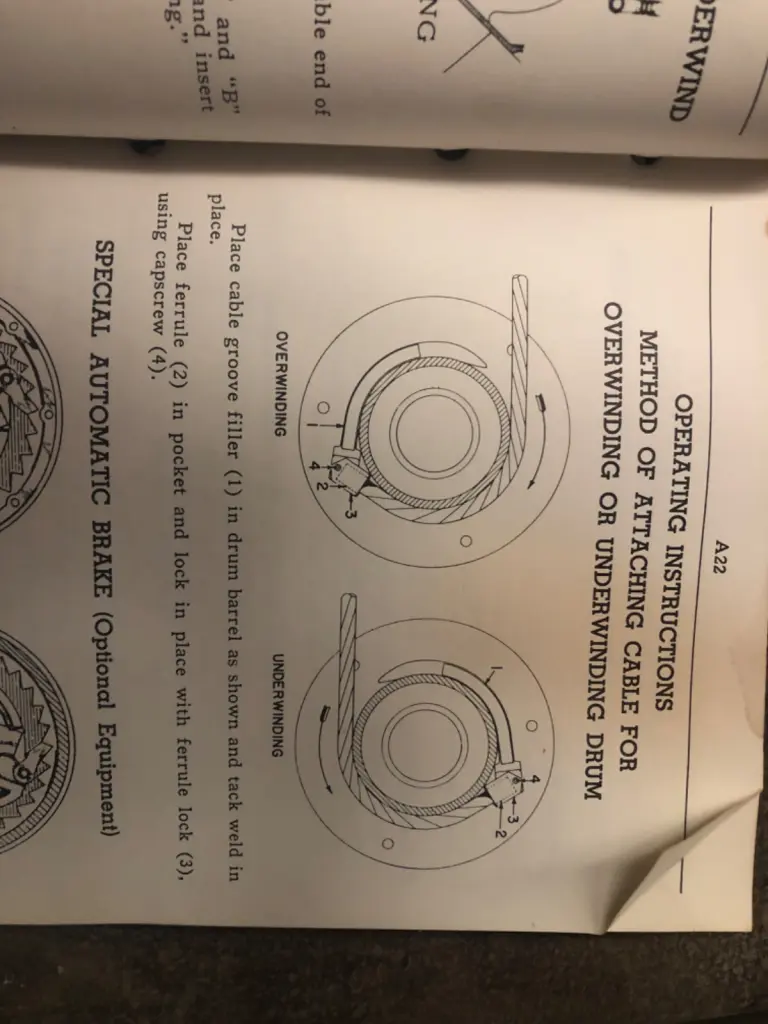

Still hoping to get insight on just running the ferrule in the pocket with the retaining cross pin, vs that plus feeding through the cross passage on the drum.

feed the cable through the drum and let the end stick into the square pocket and pour lead around itl

Yep, I believe it is the #B4, 1.63x2.00.

Still hoping to get insight on just running the ferrule in the pocket with the retaining cross pin, vs that plus feeding through the cross passage on the drum.

The passage through the drum is probably 1/2” smaller, than the O.D. Of the ferrule.

The work around would be to use wire clips at the working end. Just not as “clean” as a swedged loop.

Or…use a two piece ferrule, like what is used to repair a choker.

"i reject your reality and substitute my own" - adam savage. i suspect my final words maybe "well shit, that didnt work"

instead of perfection some times we just have to accept practicality