The threads on the track adjuster portion of that bolt or the threads in the nut are probably shot, and welding the pipe over the bolt as a spacer to hold the idler out was the answer.

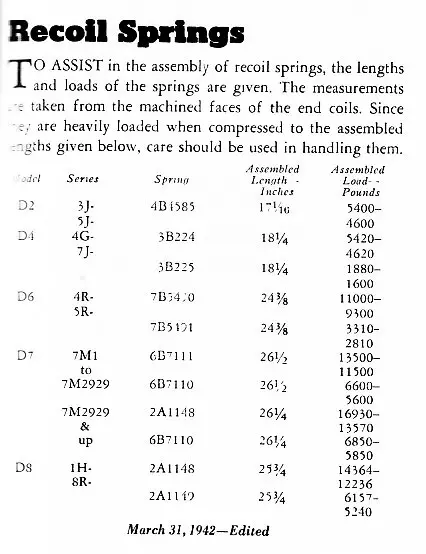

Josh would you happen to know how many tons those springs are set to? I know the spec says to adjust by length but I wondered how many tons that equates to, so whether my 12t press is up to the job of replacing the bolts and nuts.

Neil it is best to leave them alone. Suicide mission with those.

Neil it is best to leave them alone. Suicide mission with those.

You have a wonderful day. Best wishes. Deas Plant.

Hi, Neil.

The spring is at a set tension - I don't have the 'figgers', but probably around 20 tons, give or take, for a D2 - and is at a set length by design, either by a through bolt or by stops designed/built into the track frame. When you adjust the track tension, the spring stays at the same length and compression and you simply move the idler forward by turning the nut on its threaded rod - looks like those threads are shot.

I had to help repair a broken through bolt on a D9G in 1971 and I seem to remember that the compressed springs - two of them, one inside the other and coiled in opposite directions - were at 70 tons of compression - BUTTT, I could be wrong. BTW, THAT is another story which may - or may not - appear in a future magazine issue.

Just my 0.02.

This is a pretty common "field" fix. I have ran into this a couple of times and its not that big of a job to put back in spec. I can't speak to the tonnage on the d2 spring but I used my neighbors 30 ton press and it handled it with ease. One thing to note is the spring doesn't compress that much length ways, seems like 2 to 3 inches from compressed to relaxed. The first one is pucker factor for sure, but if you use some common sense its not that bad. If a replacement Cat through bolt isn't available all thread can be substituted or a machine shop can easily make one.

Put those machines back to Cat spec!

If the long bolt needs replacing, first thing I would try is to find a complete recoil spring/bolt assembly, I would think any junk yard would much rather sell you the whole assembly than fool around with trying to get the bolt out, easy to replace the whole thing.

I do not have a spec on the pressure to compress the spring.

This is a pretty common "field" fix. I have ran into this a couple of times and its not that big of a job to put back in spec. I can't speak to the tonnage on the d2 spring but I used my neighbors 30 ton press and it handled it with ease. One thing to note is the spring doesn't compress that much length ways, seems like 2 to 3 inches from compressed to relaxed. The first one is pucker factor for sure, but if you use some common sense its not that bad. If a replacement Cat through bolt isn't available all thread can be substituted or a machine shop can easily make one.

Put those machines back to Cat spec!

On the passenger side there is half a pipe on top and it either fell off the bottom or? I can see the threads there and they look rusty but good! I will do a better inspection today, do the tracks look too saggy to you all? I guess there might be a possibility of taking a track off and the threads being good at that length for the aduster? Thank you all for the sage advice!