Never welded one up here, but consider yourself somewhat lucky it did not break where the springs rest. That particular spot gets worn paper thin sometimes and difficult to repair. I have always wondered if someone could fix pans in that spot with a powder torch or spray arc? Ideally one would have to be sure of decontaminating where you plan on patching. I am guessing you didn't plan on removing it from the machine? A royal pain either way. Good luck. JM

Decided to make a patch plate and bolt it to the remaining oil pan to seal it up.

Started forming a plate to cover the hole. Going to bolt it in place, there is enough meat left on the old pan to do so. Going to take a bit to get it matched up just right. Everything is too oily to weld as well as it's location makes it tough. Onced fixed I will build a heavy duty belly pan so it never happens again.

[attachment=77185]20240721_212224.jpg[/attachment]

[attachment=77186]20240721_212249.jpg[/attachment]

[attachment=77187]20240721_183929.jpg[/attachment]

My buddy has an HT4 that does have a belly pan. We're planning to take it off to clean and I was going to suggest to leave it off and "be careful" but I'm rethinking that suggestion now : )

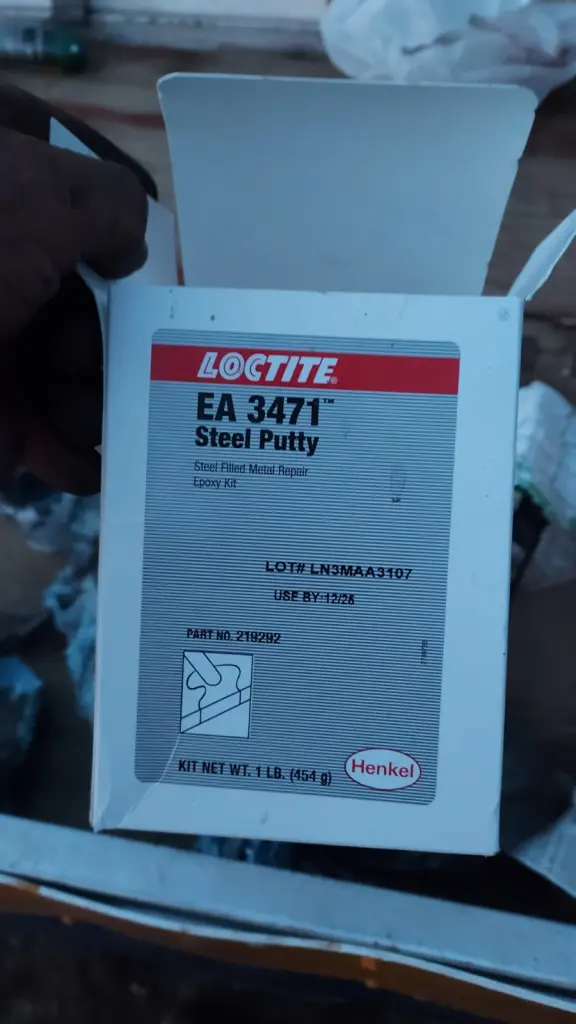

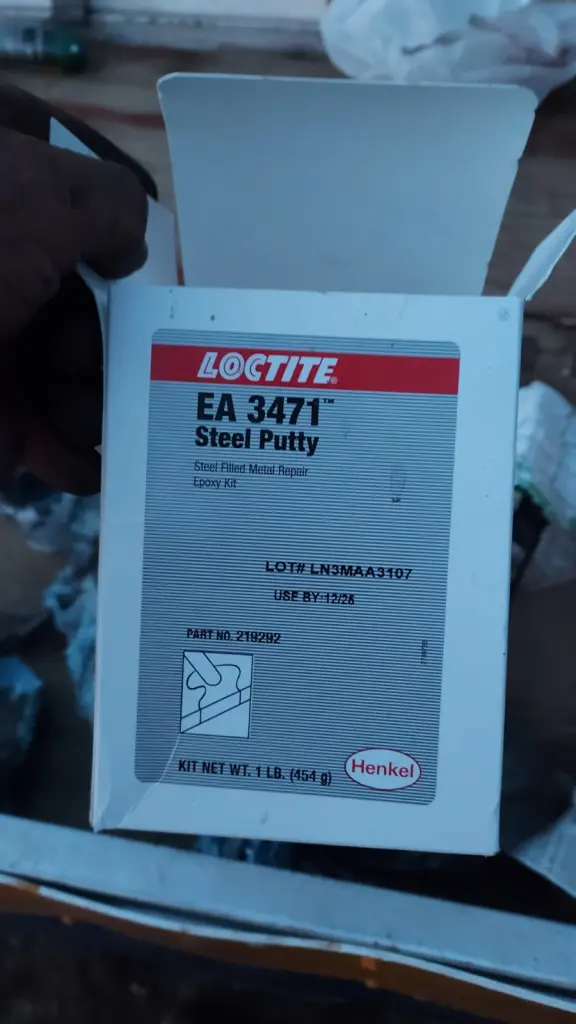

Got it all patched up. $100 worth of loctite steel putty and 2 tubes of ultra black rtv. Decided to use thru bolts to hold the plate in place instead of tapping it. Went together pretty well, very dirty work crawling under that thing. Hope the old girl is still healthy. Going to fill it with oil, turn it over for a while with the compression released and hope for the best.

[attachment=77216]20240725_210000.jpg[/attachment]

[attachment=77217]20240725_213623.jpg[/attachment]

[attahment=77218]20240725_214120.jpg[/attachment]

Cats Forever

Hope the fix holds!!!

I'd be a nervous wreck waiting for something to leak all the oil out again while operating. 😊 😊

Best of luck!! This will truly put Loctite to the test!

My D4 is an ag tractor and no belly pan which I wish it had. I use mine for a lot of demolition around the farm with the dozer and always worry about the pan.

[quote="D4Jim post=258364 userid=634"]Hope the fix holds!!!

I'd be a nervous wreck waiting for something to leak all the oil out again while operating. 😊 😊

Best of luck!! This will truly put Loctite to the test!

My D4 is an ag tractor and no belly pan which I wish it had. I use mine for a lot of demolition around the farm with the dozer and always worry about the pan.

[/quote]

Dozer is running great, no leaks or anything to be concerned about. Ended up building a huge skid plate for it that is 200-250lb and over 1" at its thickest. Worked it pretty hard for the rest of the summer with no problems.

Cats Forever