I bought a set from Eric C. ACMOC chapter 12, they were new reproduction.

I have never found any specifications in the old Sixty literature for the valve springs.

Trying to cure a "rough running engine" with new/ different valve springs will probably be disappointing. There have been several discussions about the valves being sucked down causing problems over the years, with no definitive answer.

Most of the guys that have a real smooth running Sixty at idle have set the spark way past TDC - works good at idle but not much for power, but very few of these tractors get any hard work at all.

Look to the carb and timing before you pull the heads to change springs for the valves.

[quote="phildirt"]I have never found any specifications in the old Sixty literature for the valve springs.

Trying to cure a "rough running engine" with new/ different valve springs will probably be disappointing. There have been several discussions about the valves being sucked down causing problems over the years, with no definitive answer.

Most of the guys that have a real smooth running Sixty at idle have set the spark way past TDC - works good at idle but not much for power, but very few of these tractors get any hard work at all.

Look to the carb and timing before you pull the heads to change springs for the valves.[/quote]

-agree with Phil

although its possible valve springs could be weak, it's not likely the problem..there are many other possibilities for a rough running engine..

Of course I've checked everything possible; tried know good carb, tried and correctly timed two different good magnetos, pulled front timing cover and verified valves opening properly. Good compression and no smoke. What else? I'll try spacers under the valve springs and see what happens.

Hi Team,

when putting washers under your valve springs be sure to check that the spring coils do not become coil bound/bottom out before the cam has fully opened the valve or else you will end up with bent push rods or worse still broken rocker arms for starters.

You could back off all the valve rocker arm adjustments and open the valves by hand by pushing downwards on the arm and compare how easily each valve opens and compare the findings--may find one or two weaker ones that may be getting drawn open when not required.

Just remembered that I think that the Sixty has inverted buckets over the springs so this will not work on a Sixty BUT I have found weak springs before by carefully grasping under one of the found weaker springs retainer cap and pulling upwards to assist the spring and see if this makes a change to the engine running--opposite effect of shorting a plug out.

Maybe remove all springs and check their free lengths to each other--at The Dealer we had a compression spring tester that could measure the spring force compared to a test spec. length.

It used a hydraulic cylinder of known area along with a gauge suitably calibrated to read pounds force--for a shop built rig I am thinking of a small hydraulic jack in a rig to do similar. I would choose any low pressure reading gauge and connect it to the jack and see what you get as a comparison between springs before and after stretching (as I describe below) when compressed to the average assembled valve closed length.

An easier route may be to add an inner spring to up the total spring force.

As a silly thought I would likely try the following BUT the risk is all yours--select the longest spring and warm the other springs slightly to your finger to touch--to take the chill off them, sit them in the sun or such, and then try to stretch the short ones to about 1/2" longer than the longest--then stretch the longest to match the others and retest the spring forces and compare to the pre-stretched forces.

Others may have better ideas if replacement springs are not forthcoming.

I have some spring specs here from a Cat Chart but they are for later series Gas tractors which are Gas versions of the equivalent Diesel engines of the day so their forces may be a lot higher than the 60 needs or uses and would not be a fair comparison.

Cheers,

Eddie B.

My 60 ran rough at idle but better under load. I changed mags ,spark plug wires, intake manifold gaskets,etc... Finely called a friend who is an heavy equipment mechanic. We took off the value covers and he pressed down on each value. One valve was “softer” then the rest. Turned out to be a broken valve spring in the coil closest to the head. It sits in a recess in the head and was covered in oil so I couldn’t see it. We jammed a screwdriver into the spring to increase the tension, and the 60 smoothed We replaced the valve spring by keeping the valve in place by pressurizing the combustion chamber with both valves closed.

yes i can believe a broken valve spring, maybe in a position you can't see...

but there's camshaft, camshaft lobes, lifters, rockers, perhaps pushrods, ........

potentially valve problems, valve guide....valve seat....

-what's the valve lash?

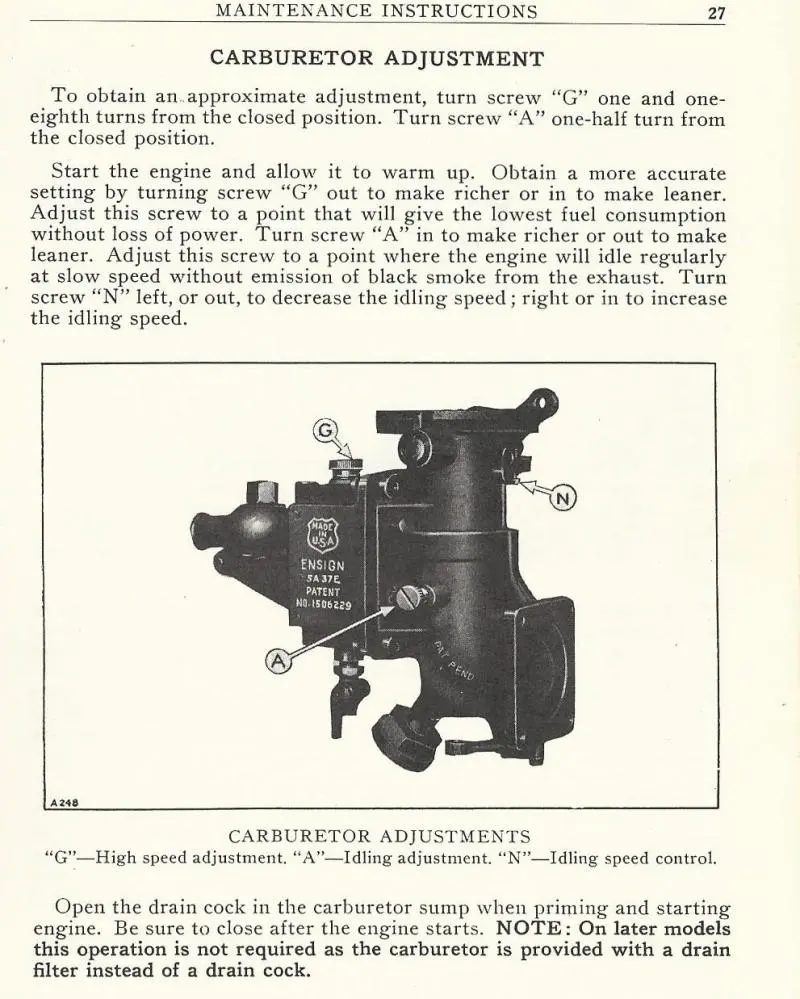

Well, I put .375 spacers under the springs (this was the max thickness to keep the springs slightly open at. 023 lash); this did not seem to affect the rough idle at all. Baffling; the engine runs ok at a higher than idle setting but seems like it should idle down smoothly. I've tried different high-speed needles and that didn't change anything, the adjustment is very sensitive and will run only with the high-speed needle almost entirely out to the point where the nut is about to come off. Could it be worn-out rings (doesn't smoke at all)? Is there an evil gremlin hiding in my motor?

What carburetor are you using on your machine?

Attached is a scan from the Operator's Manual on the Ensign AAE which was the original equipment.

Every Sixty I have been around acts differently - they were not designed to idle smoothly. The idle adjustment screw doesn't make a great change in the way my tractor idles.

Advancing the spark to fire well past TDC will probably smooth things out but everything is interconnected.

[attachment=59775]carburetor page.jpg[/attachment][attachment=59776]operator instruction book cover.jpg[/attachment]