New rollers are 8" diameter, 100% worn at 7.32"

What you are referring to as shims under the roller mounting pads are actually mounting plates. They are of a higher carbon content to minimize fretting as apposed to just running on the track frame. A 1040 designation as I recall and a desirable upgrade.

Any rolling/engaging surface that does not match new/old components is going to increase the wear rate, at least until they are compatible.

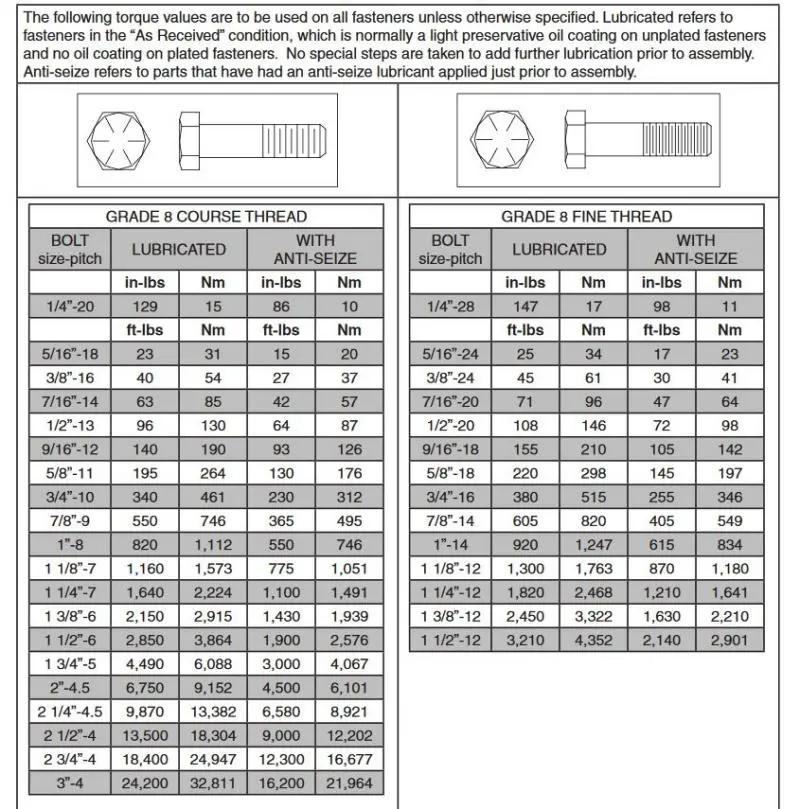

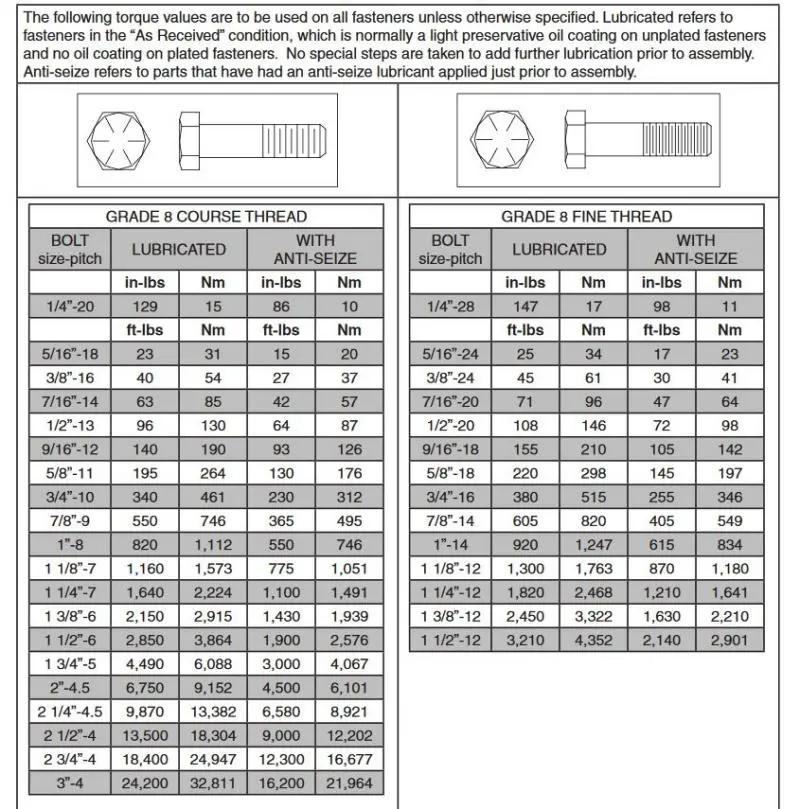

silver, it sounds like you already know this, but.. when tourqing the bolts remember a different spec for dry vs wet. if I recall ( dangerous) a dry spec of 100 ft lbs may equal about 150 actual ft lbs if you lube the bolt. some smarter members can comment and give more Intel a gent advice !

you have an abundance of motivation !!

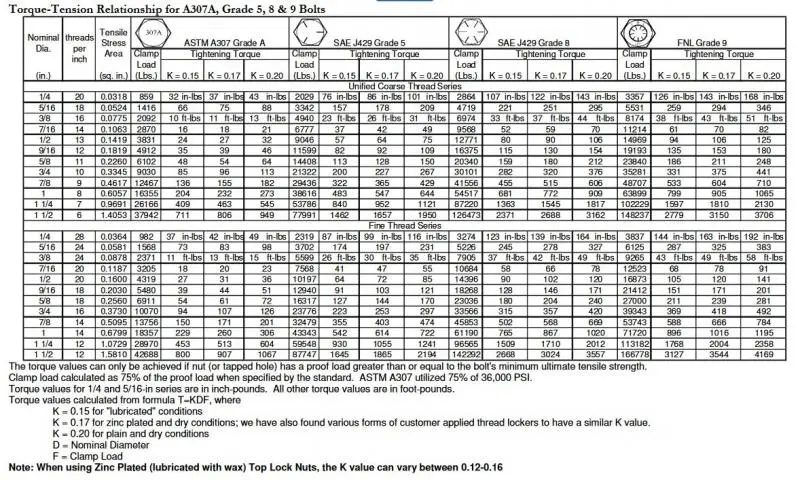

Select torque value from these charts.....

Thank you OM and TOGNOT

Old rollers on new chains can work, you will get a bit of accelerated wear until they bed in together but as there is extra height on the rails, you will be able to go past the wear limit on the rollers without flange to pin boss interference. I believe there was a change in D6 rollers that meant using a spacer when the two different part numbers were mixed, keep the spacers with the correct rollers.

Hi Silver, your 76A was originally equipped with 5/8" diameter bolts on the bottom rollers. Those bolts were prone to break and Cat increased the size of the bolts to 3/4" diameter when the D6C 10K/D6C 99J were introduced. The smaller bolts will work if you re-torque them after they "seat in" with use. The 3/4" bolts also should also be re-torqued.

The roller frame diagonal braces on all D6C/D/E were prone to develop fatigue cracks. I see in your photo that the diagonal brace on your roller frame has been repaired and a nice looking reinforcement plate added.

When you replace the rails go with S.A.L.T.(Sealed And Lubricated Track) they last longer than "dry" rails. Please note that SALT tracks must be run looser than "dry" tracks or damage to the seals and premature failure will result.

I ran D6C and D6D tractors for 23 years and found that I got the best results on new tracks by replacing the sprocket segments when the tips of the teeth got below 1/4" wide and then running the rails to destruction. I did not have luck with turning pins and bushings on SALT tracks as there were always a few links that had early seal failure.

I agree with catsilver on roller re-use.

Craig

Hi Silver, your 76A was originally equipped with 5/8" diameter bolts on the bottom rollers. Those bolts were prone to break and Cat increased the size of the bolts to 3/4" diameter when the D6C 10K/D6C 99J were introduced. The smaller bolts will work if you re-torque them after they "seat in" with use. The 3/4" bolts also should also be re-torqued.

The roller frame diagonal braces on all D6C/D/E were prone to develop fatigue cracks. I see in your photo that the diagonal brace on your roller frame has been repaired and a nice looking reinforcement plate added.

When you replace the rails go with S.A.L.T.(Sealed And Lubricated Track) they last longer than "dry" rails. Please note that SALT tracks must be run looser than "dry" tracks or damage to the seals and premature failure will result.

I ran D6C and D6D tractors for 23 years and found that I got the best results on new tracks by replacing the sprocket segments when the tips of the teeth got below 1/4" wide and then running the rails to destruction. I did not have luck with turning pins and bushings on SALT tracks as there were always a few links that had early seal failure.

I agree with catsilver on roller re-use.

Craig

Hi Silver, your 76A was originally equipped with 5/8" diameter bolts on the bottom rollers. Those bolts were prone to break and Cat increased the size of the bolts to 3/4" diameter when the D6C 10K/D6C 99J were introduced. The smaller bolts will work if you re-torque them after they "seat in" with use. The 3/4" bolts also should also be re-torqued.

The roller frame diagonal braces on all D6C/D/E were prone to develop fatigue cracks. I see in your photo that the diagonal brace on your roller frame has been repaired and a nice looking reinforcement plate added.

When you replace the rails go with S.A.L.T.(Sealed And Lubricated Track) they last longer than "dry" rails. Please note that SALT tracks must be run looser than "dry" tracks or damage to the seals and premature failure will result.

I ran D6C and D6D tractors for 23 years and found that I got the best results on new tracks by replacing the sprocket segments when the tips of the teeth got below 1/4" wide and then running the rails to destruction. I did not have luck with turning pins and bushings on SALT tracks as there were always a few links that had early seal failure.

I agree with catsilver on roller re-use.

Craig

[quote="seiscat"]Hi Silver, your 76A was originally equipped with 5/8" diameter bolts on the bottom rollers. Those bolts were prone to break and Cat increased the size of the bolts to 3/4" diameter when the D6C 10K/D6C 99J were introduced. The smaller bolts will work if you re-torque them after they "seat in" with use. The 3/4" bolts also should also be re-torqued.

The roller frame diagonal braces on all D6C/D/E were prone to develop fatigue cracks. I see in your photo that the diagonal brace on your roller frame has been repaired and a nice looking reinforcement plate added.

When you replace the rails go with S.A.L.T.(Sealed And Lubricated Track) they last longer than "dry" rails. Please note that SALT tracks must be run looser than "dry" tracks or damage to the seals and premature failure will result.

I ran D6C and D6D tractors for 23 years and found that I got the best results on new tracks by replacing the sprocket segments when the tips of the teeth got below 1/4" wide and then running the rails to destruction. I did not have luck with turning pins and bushings on SALT tracks as there were always a few links that had early seal failure.

I agree with catsilver on roller re-use.

Craig[/quote]

Thanks Seiscat. This track frame does have 3/4" diameter bolts on the bottom rollers. I would have to assume that it was updated prior to me owning this machine. It does appear that the angle brace was broken in the past and in my opinion it appears that whoever repaired it did a fine job repairing and reinforcing both top and bottom.

I am currently waiting on quotes from three suppliers for parts including SALT rails, rollers, segments and hardware. I haven't quite yet decided how many rollers to replace, I want to do some accurate measuring and see the pricing before I get too carried away. Nice to know that continuing to use the old rollers may be an option.

I will keep in mind the re-torquing advice.

Also, I did replace the front roller stand, track tensioner piston and seals, hard bar pad, and that funny shaped quarter round piece with the triangles on it that goes over the idler bridle on this fram last year so that should still be okay.

Will inspect the other side when I get it off.