Got some pix showing the cylinder in question and what went wrong with it...

1.[ Pix of plate on dozer. Can't find a part# on it.

2.&3.] The cylinder in question...

4.] Where the seal blew out.

5.] the snap ring that holds it together...

I took the 5 cap screws out of the end and removed the end keeper plate. Then cleaned all the gunk and crud off the end of the internal head and found a snap ring holding it together. When I got the snap ring out, I was able to pull the end out far enough to remove the pipe and get to the seals. I replace the one that blew out and reused the other one. Then,I pushed the head back together and tightened up the pipe. Actually, the nut on the pipe won't turn, it's not made to turn I don't think as the nut flat is right on the cylinder exterior wall. At any rate, I was able to screw the pipe into the nut with a good pair of pliers and the 'O' rings held.

But,... and that's a big but, to quote a guy I know that was observing a rather large gal on her Harley at a local rally last week end... we don't need to get into that..., But, now I've got a seep out of the weep hole in the bottom of the cylinder...? I wonder if I got the cylinder packing past the snap ring grove in the cylinder and damaged it in some way. The cylinder never leaked before the pipe seal went.

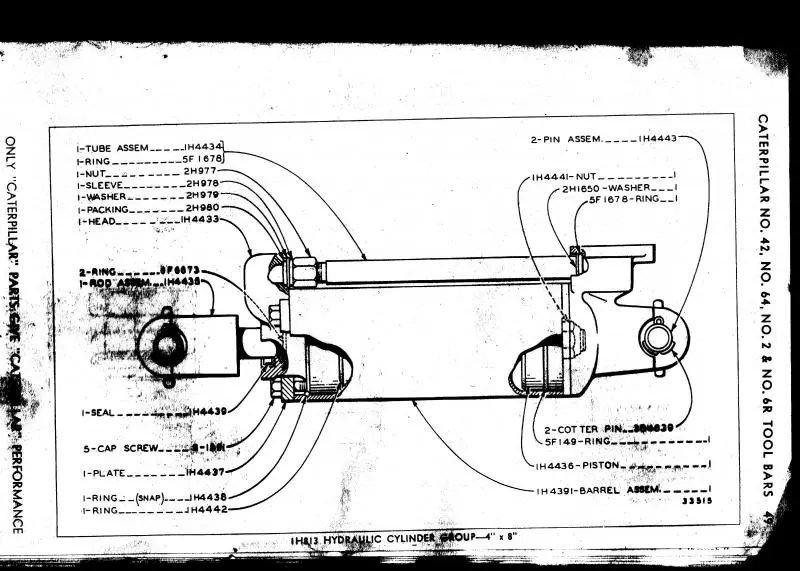

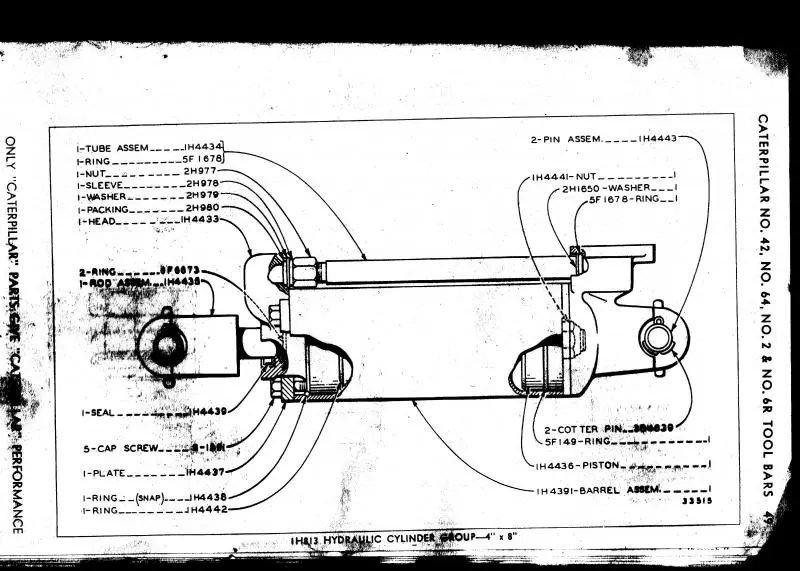

What I need is the part numbers on the "O"rings, and the other parts on the pipe seals. The packing I can get locally I think.

Any help would be appreciated and I still wonder what the number is on the dozer...?[attachment=9508]IMGP0621.jpg[/attachment][attachment=9506]IMGP0620.jpg[/attachment][attachment=9507]IMGP0622.jpg[/attachment][attachment=9505]IMGP0626.jpg[/attachment][attachment=9504]IMGP0627.jpg[/attachment]