Hope Old Magnet sees this thread, he is the only one that will know...

Early or late regular blade cylinders?

or tool bar blade cylinders?

OM, they are 1949 blade only cylinders, not sure if that is early or late.

Greg

There is more to this than regular cylinder rod.

The early cylinders have provision built in to the rod to relieve hydraulic pressure at the end of the stroke. Later cylinders had the same feature built into the piston.

If you haven't dismantled your cylinder yet I suggest you do as the amount of thread needs to be measured. Also there is a slot in the thread for the washer under the nut.

The thread on the early rod is 1-3/4 x 12tpi (NF). I'm assuming the later is the same.

If you use the Cat piston cups they need a 1/16" back up washer (teflon) to prevent them from being blown out.

If you have the later cylinders try and work out a sealing ring replacement with your local hydraulic shop as Cat has totally screwed up this arrangement with multiple piston rings as replacements.

[quote="Old Magnet"]There is more to this than regular cylinder rod.

The early cylinders have provision built in to the rod to relieve hydraulic pressure at the end of the stroke. Later cylinders had the same feature built into the piston.

If you haven't dismantled your cylinder yet I suggest you do as the amount of thread needs to be measured. Also there is a slot in the thread for the washer under the nut.

The thread on the early rod is 1-3/4 x 12tpi (NF). I'm assuming the later is the same.

If you use the Cat piston cups they need a 1/16" back up washer (teflon) to prevent them from being blown out.

If you have the later cylinders try and work out a sealing ring replacement with your local hydraulic shop as Cat has totally screwed up this arrangement with multiple piston rings as replacements.[/quote]

Thanks much for the info, OM!

G

I am working on cylinders now. I have the 3 ring type piston and have some questions. Are those rings supposed to be real loose and able to spin in the piston or is it normal to be relatively tight in the ring grooves?

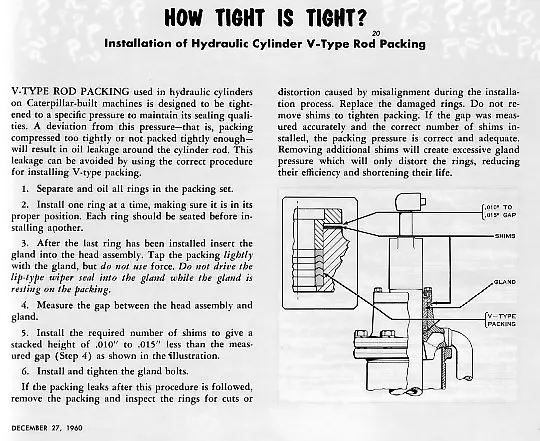

How does one know how many shims to use, or take out, to compress the packing that seals the shafts? My shafts were a little rough and the dust seals wiped right out so they were leaking oil pretty bad. I smoothed out the shafts, and am replacing the dust wipers, but am wondering about removing a shim or two to put more pressure on the shafts. I'm assuming how this all works. First time into the hydraulics. They sure are massive.

The rings should be relatively snug to prevent excess motion from the back and forth movement. It is not necessary that they seat and not revolve like piston rings.

Your right on with the packing shims. The shim adjustment is there to provide compression to the chevron seals. It's a bit tricky to come up with just enough pressure to prevent leakage without being to tight on the rod.

Thank you OM.

If I install the cylinder cap and take a shim or two out, and tighten the gland bolts, should I be able to slide the assembly back and forth on the rod with some resistance, or should it be so tight I can't move it by hand? I'm thinking there should be a good deal of resistance because under hydraulic pressure, it's going to move and somewhat seat in or loosen up when in action. ???? I'm thinking I would try to make this adjustment before installing the piston and assemble the cylinders.

A hydraulic guy told me to leave the rings alone because I would break them, but they seemed jammed so I took them off and shaved some of the fur off the edges and loosened them up a bit. I can now rotate them in the grooves, but they are snug with no play. I realize that the oil pressure will get behind them and push them out to the bore as they operate, but they just seemed too tight.

I'm going together, we,ll see what happens. I figure with actually having dust seals, they will be better than before. They worked fine, just leaked too much.

I'd do as you say, remove no more than two shims. I'd expect the result to make it to difficult to move the rod by hand without some assistance. If the packing rings are dried out and brittle they should be replaced otherwise shim removal is standard practice.

Your description of the piston rings sounds fine.