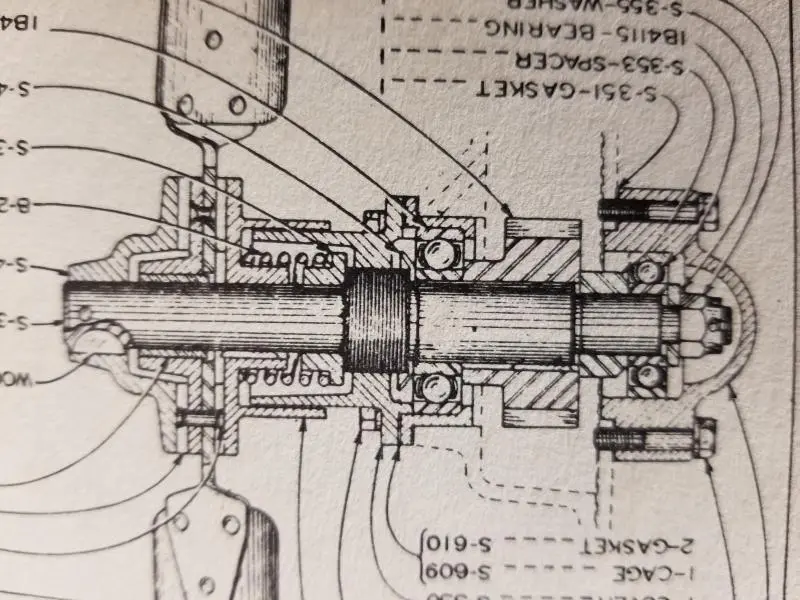

Very easy to replace once you get the radiator off. Be prepared to find that the shaft needs to be repaired or replaced due to shaft wear in the spring pressure fan drive area. I turned a new shaft and repaired the floating part that rubs on the friction .

I agree, when I had mine out both bearings were rough and the shaft was worn, I replaced the bearings with sealed bearings and had the shaft spray welded and turned true.

Or with Stephens skills with a lathe you would just make a new shaft.