Well as some of you know I have been working on getting my D2 back up and running. I have had to deal with many small issues on both the diesel, and pony motor. Tuesday afternoon I was finally satisfied that both were ready to run. I fired up the pony and it ran for less than a minute then seized. Not a good sign. Yesterday I pull the top off and see that the rod cap has decided to part ways with the rod. A messy divorce to say the least, and one that will of course cost me dearly.

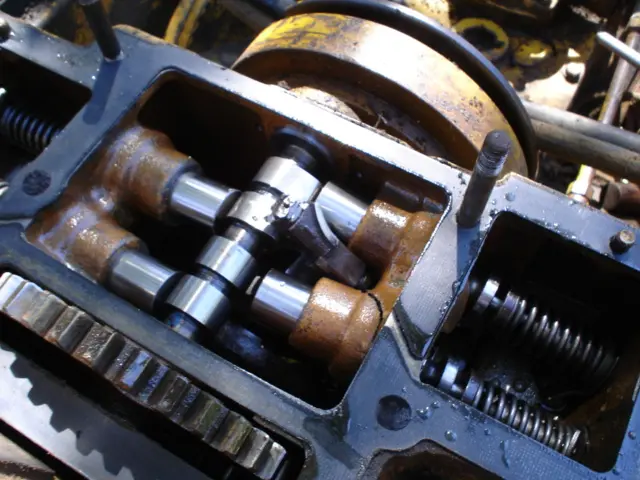

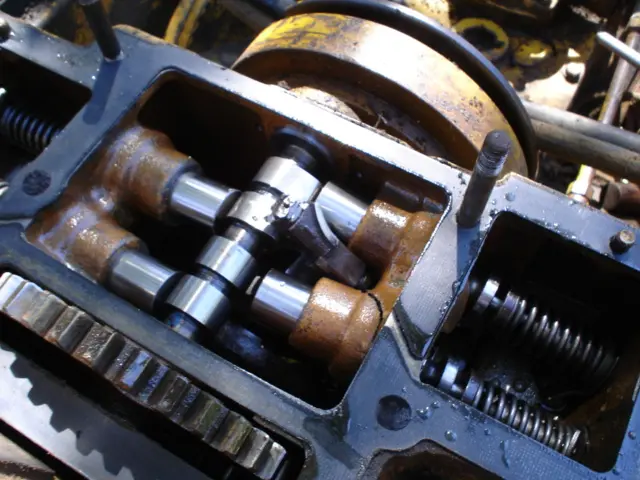

The rod nut that can be seen in the picture is only finger tight and missing the cotter pin. The other piece of the rod cap that I fished out of the bottom of the crankcase is still torque down and holding the two pieces firmly together. It is missing the cotter pin as well. The other rod has both cotter pins in place.

My dad has another pony motor that has a cracked block from freezing. I’m going to take a look at it today and see if any of it is salvageable, and possibly see if it can be welded up. (A long shot I know) What I find there will determine how I resolve this issue.

I think now is a good time to straighten out that bent fender. I’ll just use a really small hammer so I don’t hurt anything.