The original design was two lines running to the sediment bowl, one from each end of the tank. This was so the tractor wouldn't starve for fuel going up or down slopes. I couldn't tell you the last time I opened the rear valve on mine. I have gotten in the habit of just running off the front one, I guess since it is the easiest to reach when starting the tractor. I have never had any problems with the tractor getting enough fuel off of just the one line. I drain mine off the sediment bowl when needed, although I run ethanol-free gas and it seems to do fine even if I go a few months between starts.

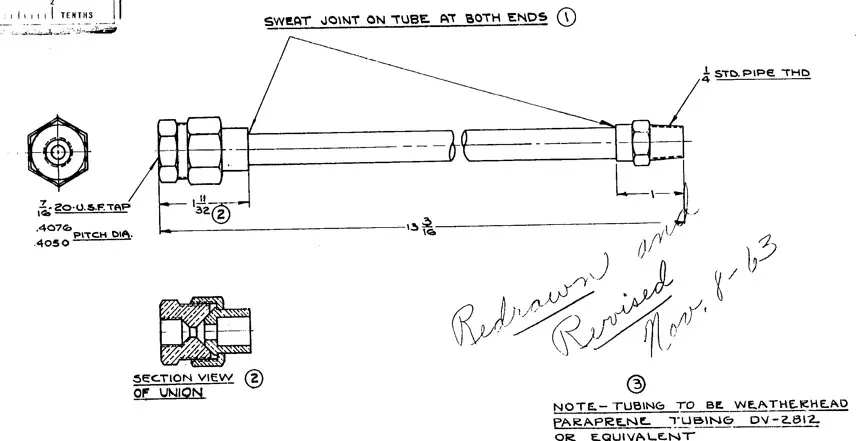

The drawing for the lines calls for 1/4" Weatherhead Paraprene Tubing. The version of the drawing that is available is from 1931 when the material was changed to that. I don't know what it called for when it was originally created in 1928. In 1963 the drawing changed again to a more modern crimped-end fuel hose. I just did mine out of rubber fuel line and they work fine. I got about 10 years out of my brass shut-off valves before they started to weep and I had to replace the whole setup again.

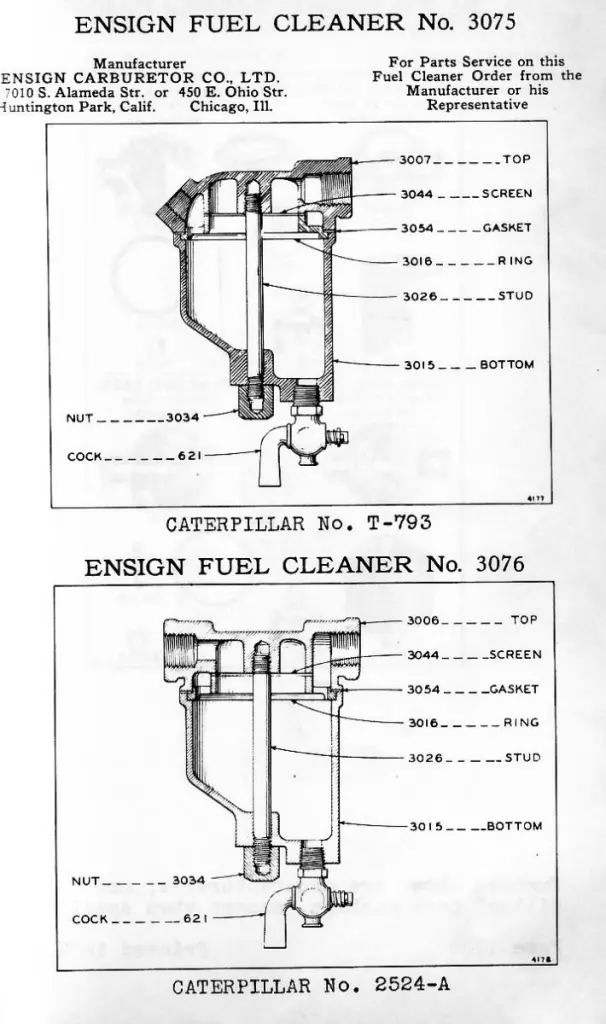

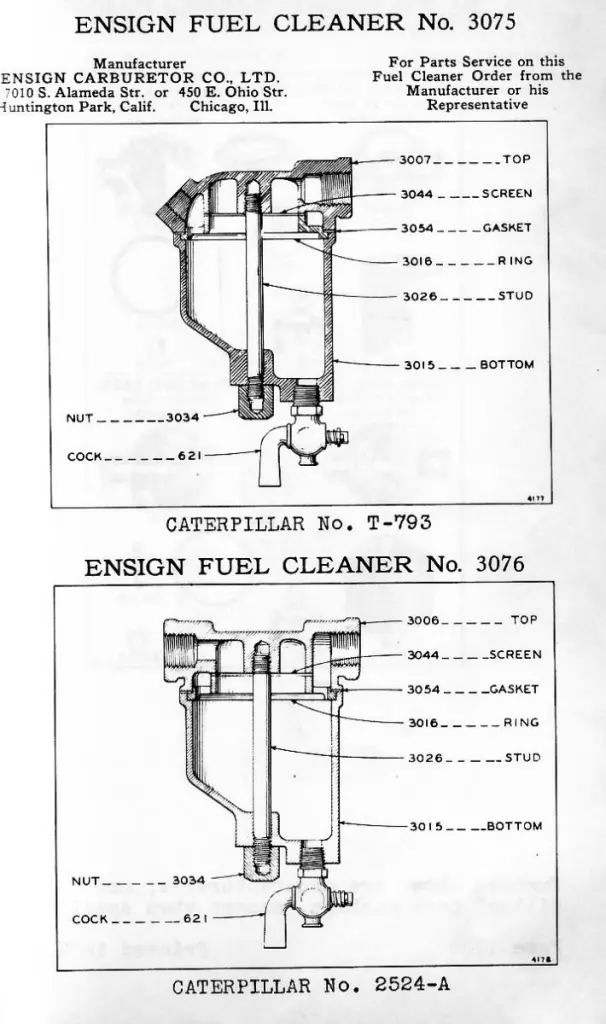

My sediment bowl didn't have a screen inside it, but there was a screen at the banjo fitting where it attaches to the carburetor. I have some documentation from Ensign that does show a screen for the sediment bowl with that part number, but the part in their illustration doesn't look like the original bowl. FWIW, That banjo fitting is the weakest link in my whole fuel system setup. I've only got a couple threads left in the carb where that attaches, so it is a fine line between getting it tight enough so it doesn't leak all over, and stripping it out. I think this is common due to the carbs being made out of cheap metal, and the weight of the sediment bowls hanging off of there.

Hope this helps, and good luck with your project,

Dave

Question Re: fuel lines on Ten

Are both fuel tanks the same size? One filler cap or two?

Some of the early tractors of many manufactures had two tanks - One for gasoline and one for distillate. Started machines on Gasoline and then when warm went to distillate. Gasoline would have been the smaller tank in that case.

That would explain the two lines.

Assuming the tank(s) are directly in front of the operator - it is doubtful it would make much difference which one was drawn from in most cases - full tanks would supply fuel by gravity.

Fuel lines- there are some very good products used today that are way superior to the old "rubber-fiber" hose that was standard at time built.

I know of no reason why copper tubing will not work for fuel line if you are looking for solid line. It was used for years in many applications.

Fuel leaks are not something to take lightly - use quality materials and ensure they remain leak free.

CTS

HI Dave! I find this print interesting, as I find most Cat prints. That I am trying to figure out is how you "sweat" a rubber tube onto the fittings at the end. A junk Fifteen that I brought in had a set of crimped hoses on it and that is how I have recreated the ones on another Fifteen. If I could have gotten the hose place to use the original ends I would have. I do not under stand how so many of those carb's top covers have survived as there is with that heavy brass sediment bulb hanging off of them. The die cast one is better for weight but not much.

Ken

"i reject your reality and substitute my own" - adam savage. i suspect my final words maybe "well shit, that didnt work"

instead of perfection some times we just have to accept practicality