Thanks for the reply. Did you have to take the starting engine off the Diesel engine to fix the clutch. Hope I don't have to do that. I'm going to try Pete's idea first.

Dave, you didn't say that you are only adjusting one hole between too loose & top tight. How about adjusting slowly until you get the over center adjustment you can live with, and then ignoring any extra slack? I'm thinking there is something past worn there, and you do have to pull the pony to work that angle.

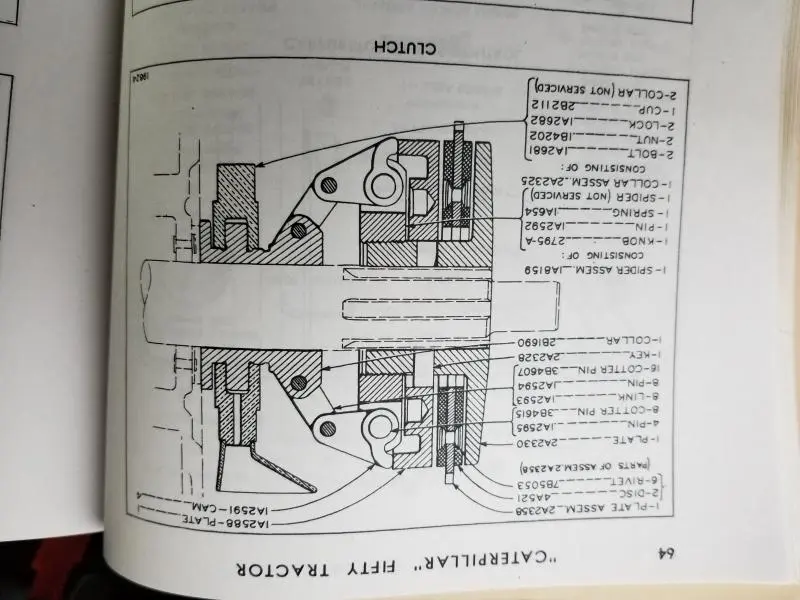

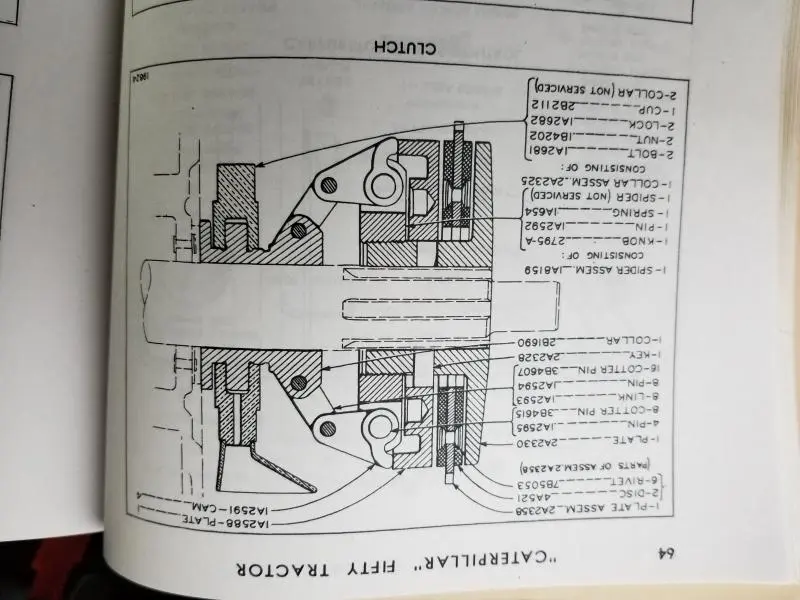

Here are a few of the photos of the clutch disc failure I had on my RD6, should be almost an identical setup to your D50. I had a good over-center snap on the clutch lever but it would slip badly while driving the diesel under full compression unless I held additional force on the clutch lever by hand, then it would at least spin the diesel until I took my hand off the lever. The first thing I tried was adjusting the clutch tighter but the next available hole made it so tight that it was impossible to snap it over center by hand, but again holding lots of pressure on the lever made it possible to spin the engine but I didn't want to have to operate it like that. So I removed the starting engine and clutch assembly and found that the clutch frictions had come loose from the rivets that were supposed to be holding them to the center steel disc. It seems that the pressure exerted on the loose disc pieces by the over-center pressure plate was not enough to transmit the power without them slipping against themselves without additional force being manually applied through the hand lever. Even at that point, I believe there was still some slippage happening. Of course, try all possible adjustments before tearing into it, hopefully it'll be something simple that solves your problem. If not, these pics may be of some help -

First pic, damaged clutch disc with the loose frictions sitting next to a freshly re-lined one.

Second pic, re-lined disc with all clutch components ready for reassembly.

Third pic, fully assembled clutch ready to be bolted up to the starting engine again.