There should be some YouTube tutorials. I have a D4 pony start so I know the fundamentals but a D8 has somewhat different levers and valves I believe. I know it is important to always shut off the pony by cutting the fuel off and letting it run dry, always make sure the pony crankcase oil is not diluted with gasoline (level, smell, touch), there is also a low speed for turning engine and a high speed for starting. A D7 pony start should be the same as it is a 4cyl version of a D8 engine so if you search that on youtube, that should be useful. I would send you a link but I do not have wifi and dont want to use up all my data. Whereabouts are you? I am in Vernon and was in Cherryville today.

Nathan

catCat8235,

Let me begin by thanking you for joining our club. We appreciate every new member to help further our cause.

The starting sequence would be as follows.

-On your dashboard, the gas valve for the pony motor is in the extreme right lower corner. Open that valve first. The ignition switch is in the upper left hand corner which you will turn to "On." Below that are the choke and throttle knobs. Pull out the choke and set the throttle about midway.

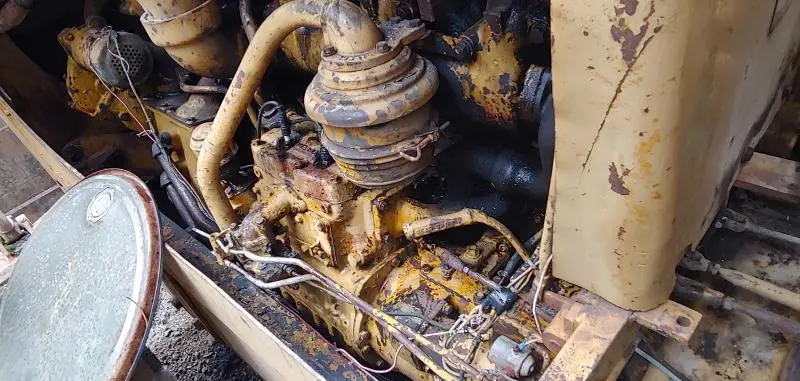

- The handle (photo 2) on the right side of the firewall has two positions marked with tags "Start" and "Run." This lever is the compression release. Set it to "Start." Also be sure the machine is out of gear or the powershift lever has the safety pulled up.

- The handle (photo 4) down by the pony transmission has two positions - "Low" and "High." If you are down in Antarctica, set it in the "Low" position for a while, (like maybe two hours) then go to "High." Otherwise, have it in the "High" position.

- The main engine throttle is the bent lever on the right side of the steering lever box. When starting, have that in the Off position which is all the way forward away from the operator.

- Now start the pony motor and let it warm up. Depending on the air temperature, that will be a minute or two or a little longer until it is running smoothly. Now open the pony throttle up to full throttle.

- Pull the handle (photo 3) on the left side of the steering lever box out to engage the pinion to turn the main engine over. If adjusted properly, it will stay out on its own, otherwise you can hold it out. Watch the oil pressure gauge until it comes up into the green.

- With the main turning over with oil pressure, move the compression release to the "Run" position. Let the main engine warm up under compression depending on the air temperature. In winter starting, it is best to not short circuit this process.

- Once warm, pull the main throttle back half way towards the operator and with the introduction of fuel, the wonderful experience of seeing the black smoke roll out of the exhaust as the big mill comes to life will "make your day."

- With the starting of the main engine, the pinion will release (or let go of it if you are holding it) then throttle down the pony motor and shut off the gas valve leaving it to run out of gas. As already said, this prevents gas from thinning out the engine oil in the pony.

The 8Hs are quite straightforward from earlier models. If you did not get any manuals with the tractor, you need to go on eBay for the Service Manual, Parts Manual and Operators Manuals so you have complete knowledge of the machine for lubing, repairing and adjusting it. Be sure to check the Serial Number to be sure it is within the spread of serial numbers for which the books are published.

Have fun with your new tractor. It is a toss-up for me between the 14As and 46As for which is my favorite Caterpillar tractor!

JanM

There should be some YouTube tutorials. I have a D4 pony start so I know the fundamentals but a D8 has somewhat different levers and valves I believe. I know it is important to always shut off the pony by cutting the fuel off and letting it run dry, always make sure the pony crankcase oil is not diluted with gasoline (level, smell, touch), there is also a low speed for turning engine and a high speed for starting. A D7 pony start should be the same as it is a 4cyl version of a D8 engine so if you search that on youtube, that should be useful. I would send you a link but I do not have wifi and dont want to use up all my data. Whereabouts are you? I am in Vernon and was in Cherryville today.

Nathan

I am over In Celista

[quote="Mangoman"]There should be some

YouTube tutorials. I have a D4 pony start so I know the fundamentals but a D8 has somewhat different levers and valves I believe. I know it is important to always shut off the pony by cutting the fuel off and letting it run dry, always make sure the pony crankcase oil is not diluted with gasoline (level, smell, touch), there is also a low speed for turning engine and a high speed for starting. A D7 pony start should be the same as it is a 4cyl version of a D8 engine so if you search that on youtube, that should be useful. I would send you a link but I do not have wifi and dont want to use up all my data. Whereabouts are you? I am in Vernon and was in Cherryville today.

Nathan[/quote]

Hi and Welcome,

this video for a D7E that has same controls as the D8H.

Many videos of how to wreck/abuse a pony engine on YouTube.

This one is nearly there except he does not begin with the Diesel on De-compression until Oil Pressure registers on the gauge and run for at least 60 seconds or so to allow oil to reach all points needed.

The time to run the Diesel on Full Compression before attempting a Start is determined by the ambient temperature and/or how warm the Diesel engine is since it last ran if within the hour or so.

https://www.youtube.com/watch?v=A4EV39Mwm08

Hope this helps.

Cheers,

Eddie B.

catCat8235,

Let me begin by thanking you for joining our club. We appreciate every new member to help further our cause.

The starting sequence would be as follows.

-On your dashboard, the gas valve for the pony motor is in the extreme right lower corner. Open that valve first. The ignition switch is in the upper left hand corner which you will turn to "On." Below that are the choke and throttle knobs. Pull out the choke and set the throttle about midway.

- The handle (photo 2) on the right side of the firewall has two positions marked with tags "Start" and "Run." This lever is the compression release. Set it to "Start." Also be sure the machine is out of gear or the powershift lever has the safety pulled up.

- The handle (photo 4) down by the pony transmission has two positions - "Low" and "High." If you are down in Antarctica, set it in the "Low" position for a while, (like maybe two hours) then go to "High." Otherwise, have it in the "High" position.

- The main engine throttle is the bent lever on the right side of the steering lever box. When starting, have that in the Off position which is all the way forward away from the operator.

- Now start the pony motor and let it warm up. Depending on the air temperature, that will be a minute or two or a little longer until it is running smoothly. Now open the pony throttle up to full throttle.

- Pull the handle (photo 3) on the left side of the steering lever box out to engage the pinion to turn the main engine over. If adjusted properly, it will stay out on its own, otherwise you can hold it out. Watch the oil pressure gauge until it comes up into the green.

- With the main turning over with oil pressure, move the compression release to the "Run" position. Let the main engine warm up under compression depending on the air temperature. In winter starting, it is best to not short circuit this process.

- Once warm, pull the main throttle back half way towards the operator and with the introduction of fuel, the wonderful experience of seeing the black smoke roll out of the exhaust as the big mill comes to life will "make your day."

- With the starting of the main engine, the pinion will release (or let go of it if you are holding it) then throttle down the pony motor and shut off the gas valve leaving it to run out of gas. As already said, this prevents gas from thinning out the engine oil in the pony.

The 8Hs are quite straightforward from earlier models. If you did not get any manuals with the tractor, you need to go on eBay for the Service Manual, Parts Manual and Operators Manuals so you have complete knowledge of the machine for lubing, repairing and adjusting it. Be sure to check the Serial Number to be sure it is within the spread of serial numbers for which the books are published.

Have fun with your new tractor. It is a toss-up for me between the 14As and 46As for which is my favorite Caterpillar tractor!

JanM

[quote="janmeermans"]catCat8235,

Let me begin by thanking you for joining our club. We appreciate every new member to help further our cause.

The starting sequence would be as follows.

-On your dashboard, the gas valve for the pony motor is in the extreme right lower corner. Open that valve first. The ignition switch is in the upper left hand corner which you will turn to "On." Below that are the choke and throttle knobs. Pull out the choke and set the throttle about midway.

- The handle (photo 2) on the right side of the firewall has two positions marked with tags "Start" and "Run." This lever is the compression release. Set it to "Start." Also be sure the machine is out of gear or the powershift lever has the safety pulled up.

- The handle (photo 4) down by the pony transmission has two positions - "Low" and "High." If you are down in Antarctica, set it in the "Low" position for a while, (like maybe two hours) then go to "High." Otherwise, have it in the "High" position.

- The main engine throttle is the bent lever on the right side of the steering lever box. When starting, have that in the Off position which is all the way forward away from the operator.

- Now start the pony motor and let it warm up. Depending on the air temperature, that will be a minute or two or a little longer until it is running smoothly. Now open the pony throttle up to full throttle.

- Pull the handle (photo 3) on the left side of the steering lever box out to engage the pinion to turn the main engine over. If adjusted properly, it will stay out on its own, otherwise you can hold it out. Watch the oil pressure gauge until it comes up into the green.

- With the main turning over with oil pressure, move the compression release to the "Run" position. Let the main engine warm up under compression depending on the air temperature. In winter starting, it is best to not short circuit this process.

- Once warm, pull the main throttle back half way towards the operator and with the introduction of fuel, the wonderful experience of seeing the black smoke roll out of the exhaust as the big mill comes to life will "make your day."

- With the starting of the main engine, the pinion will release (or let go of it if you are holding it) then throttle down the pony motor and shut off the gas valve leaving it to run out of gas. As already said, this prevents gas from thinning out the engine oil in the pony.

The 8Hs are quite straightforward from earlier models. If you did not get any manuals with the tractor, you need to go on eBay for the Service Manual, Parts Manual and Operators Manuals so you have complete knowledge of the machine for lubing, repairing and adjusting it. Be sure to check the Serial Number to be sure it is within the spread of serial numbers for which the books are published.

Have fun with your new tractor. It is a toss-up for me between the 14As and 46As for which is my favorite Caterpillar tractor!

JanM[/quote]

Yep, that's the go. My 9 is very similar

Only thing I'll add is I push the engagement handle back for about 5 seconds or so and pull it back fairly quickly. Can get a bit of grinding otherwise.

I've also found in hot weather or when the machine is warm the gauge won't get into the green with the pony, it'll just sit in the white. as soon as the machine starts it's straight up into the green though.

Thank you again

QUOTE=Misterskill;228422]Yep, that's the go. My 9 is very similar

Only thing I'll add is I push the engagement handle back for about 5 seconds or so and pull it back fairly quickly. Can get a bit of grinding otherwise.

I've also found in hot weather or when the machine is warm the gauge won't get into the green with the pony, it'll just sit in the white. as soon as the machine starts it's straight up into the green though.[/QUOTE]

You have a wonderful day. Best wishes. Deas Plant.

Hi, catCat8235.

Welkum to Yellow Fever land.

Misterskill's amendment to Janmeerman's post is correct. Pushing the pinion control handle in hard for a few seconds before pulling it quickly all the way out stops the pinion from rotating and thus makes it easier to engage with the ring gear on the diesel flywheel.

Otherwise, proceed as directed and the best of luck.

Just my 0.02.