Two men, two pry bars.

Bar seemed to get it tight.... Thanks

just curious, is there a torque spec for the sprocket bearing? or tolerance of movement?

- i'm more of a numbers guy...

The book says to use a 5' cheater bar and tighten it as tight as you can.

okay thanks Rusty....that sounds TIGHT!

just curious, is there a torque spec for the sprocket bearing? or tolerance of movement?

- i'm more of a numbers guy...

"i reject your reality and substitute my own" - adam savage. i suspect my final words maybe "well shit, that didnt work"

instead of perfection some times we just have to accept practicality

"i reject your reality and substitute my own" - adam savage. i suspect my final words maybe "well shit, that didnt work"

instead of perfection some times we just have to accept practicality

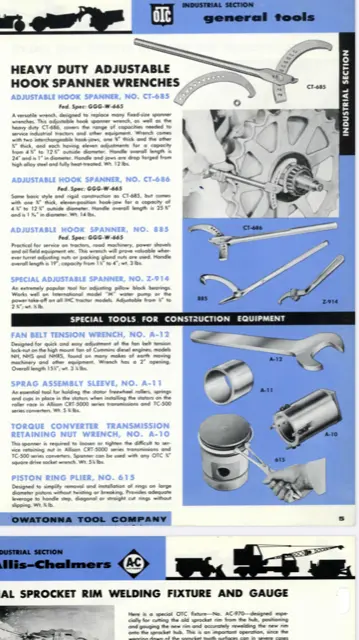

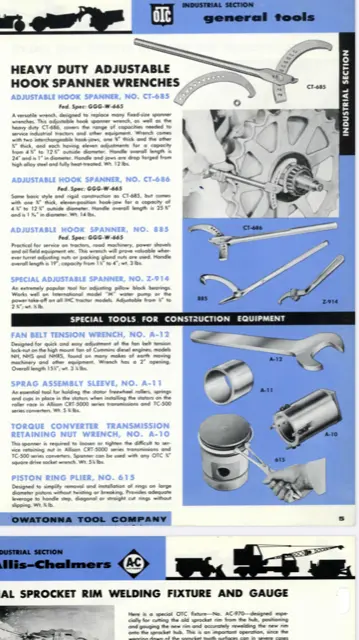

OTC 7308 and 7309 are available nowadays to do the job but at a price.. I found a copy of a 1959 OTC tool catalogue online that had the same wrench as 7309 previously listed as CT-686. I kept an eye on eBay for this version and scored one for $66. Worth looking out for as there's no substitute for the correct tool, makes the job very straightforward and when I removed the adjusting nut from a parts machine so much quicker than a brass drift.

[attachment=61099]IMG_7817.jpg[/attachment]

[attachment=61101]IMG_8412.PNG[/attachment]