Reply to rehpig:

What’s your opinion on the two that are spraying? Do you suggest going CAT direct on the injectors

Hi Team,

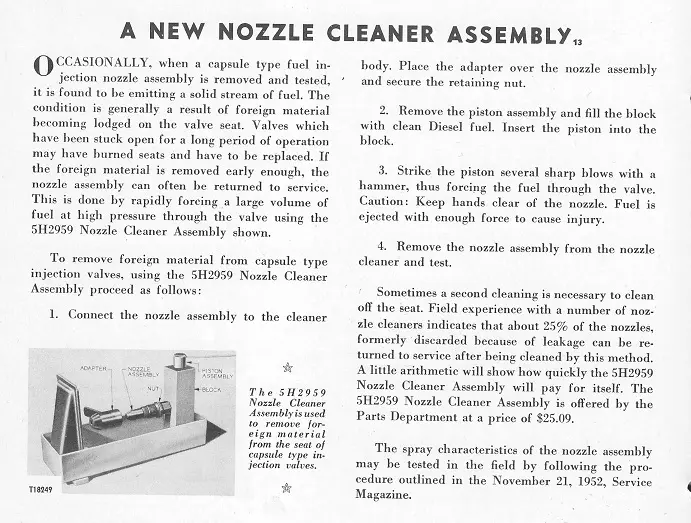

it is not unknown for a few new capsule injectors to not open and spray from new--usually clients, via Parts Dept. and before Warranty was granted, bought them in to the Dealer Injection Shop for us to put on a hand pump injector tester and so give the pump handle a decent pump and so start them working correctly.

By the using the same style pumping action clogged or off spray pattern nozzles would come good.

Any used, clogged and non-acceptable spray pattern nozzles were put in our Ultra-sonic bath for cleaning most often with excellent results.

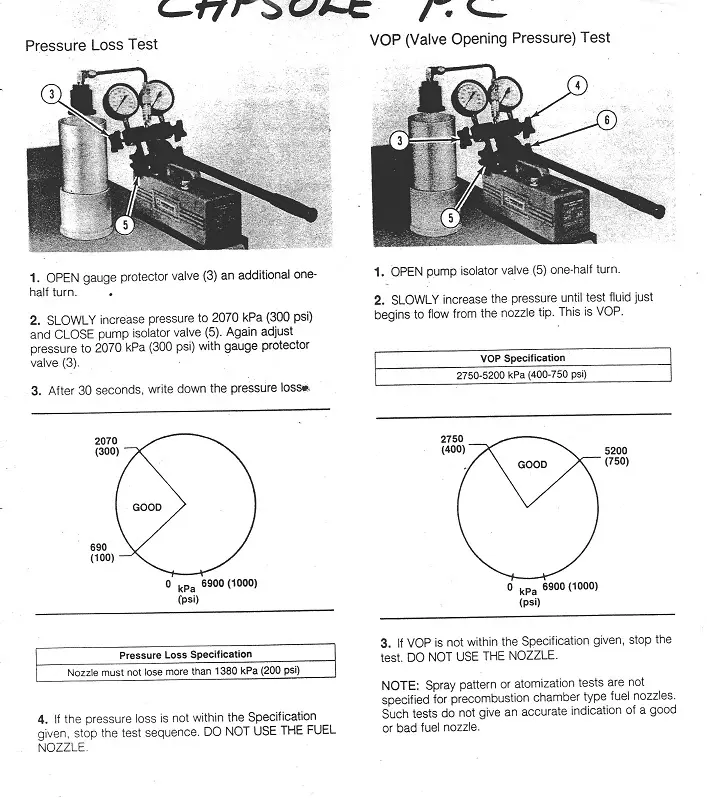

A 0.028" drill can gently be used to clear the orifice of carbon and so may restore the spray pattern if the opening pressure of between 400 and 750 PSI. is correct.

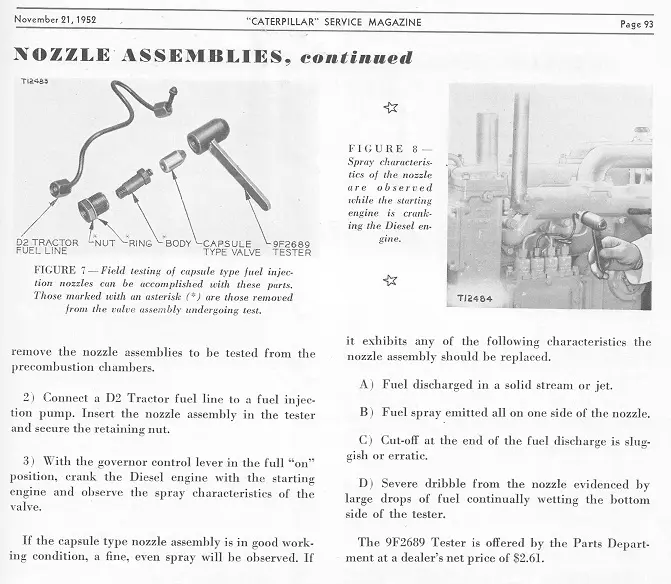

The test for pressure loss from 300 PSI after 30 seconds should be no more than 200 PSI. (300 down to 100 PSI)

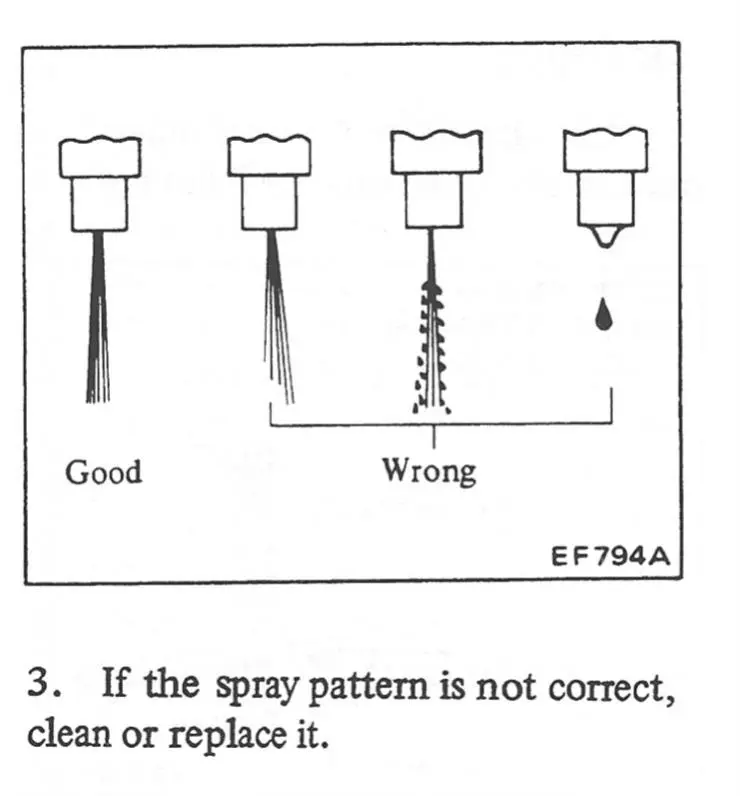

Scan below may help for the test procedure (described above) that we used both before and after ultra-sonic cleaning.

If your new after market or Cat nozzles are not working as designed then apply for Warranty and receive new nozzles in exchange.

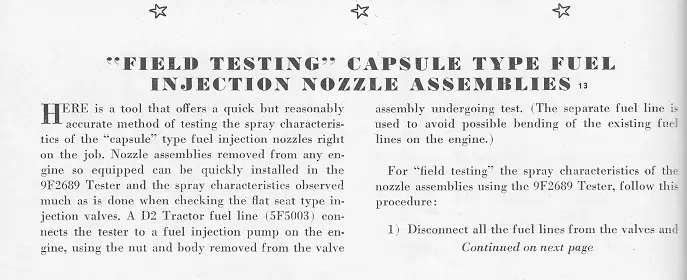

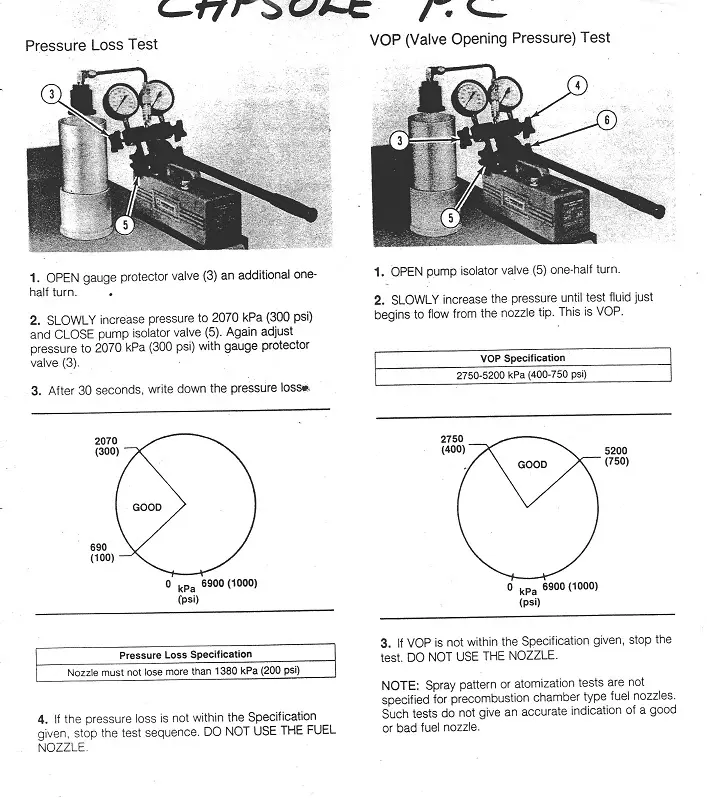

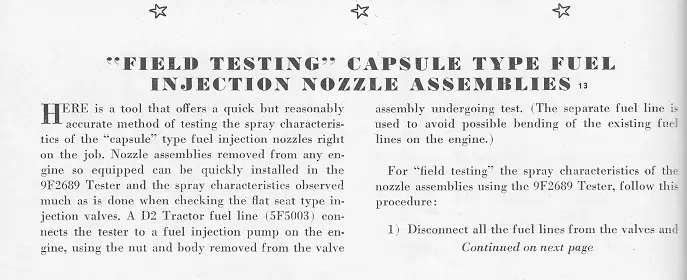

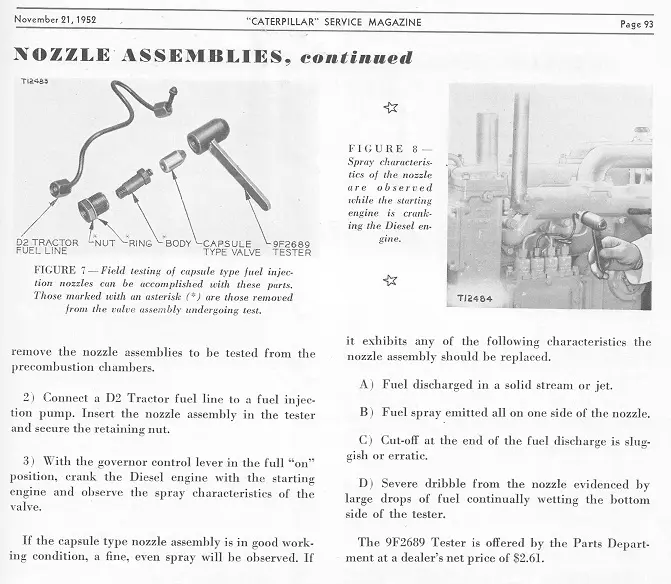

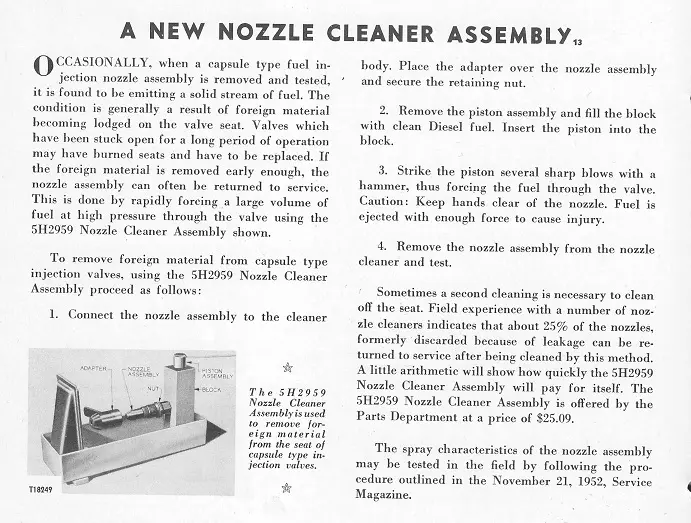

Scans below show various testers and procedures from long ago--the principles are the same when using a Commercially available injector nozzle pump tester as I described above.

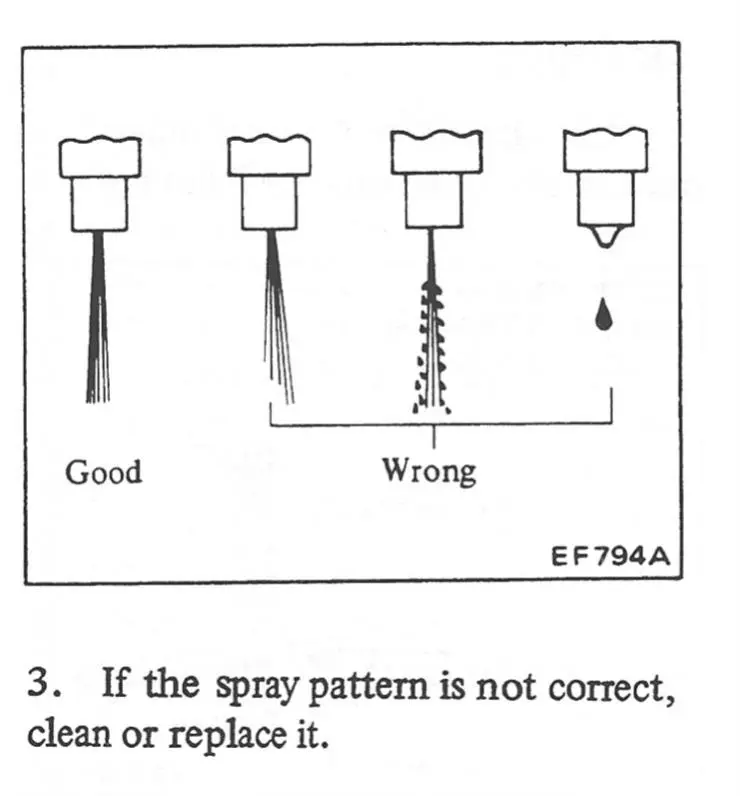

Also explained are the expected test pattern results. Scan of spray patterns are from Google as a visual comparison only.

Cheers,

Eddie B.