Under the category of what else? One of our local mechanics used to put more response in the 3T's by installing 46A governor weights. He said that they were lighter than the stock 3T weights and as such the engine would respond much more quickly to an increasing load. I talked to a farmer that he did it for and he was really mad that he hadn't done it 30 years sooner. He was sure cussing all the extra hours that he spent on the D7 when he could have had something that responded well.

Casey

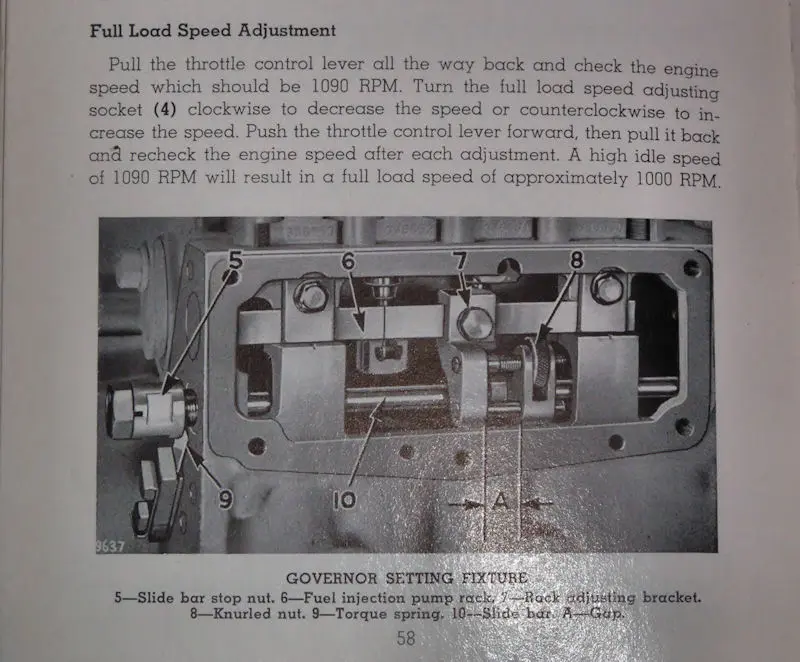

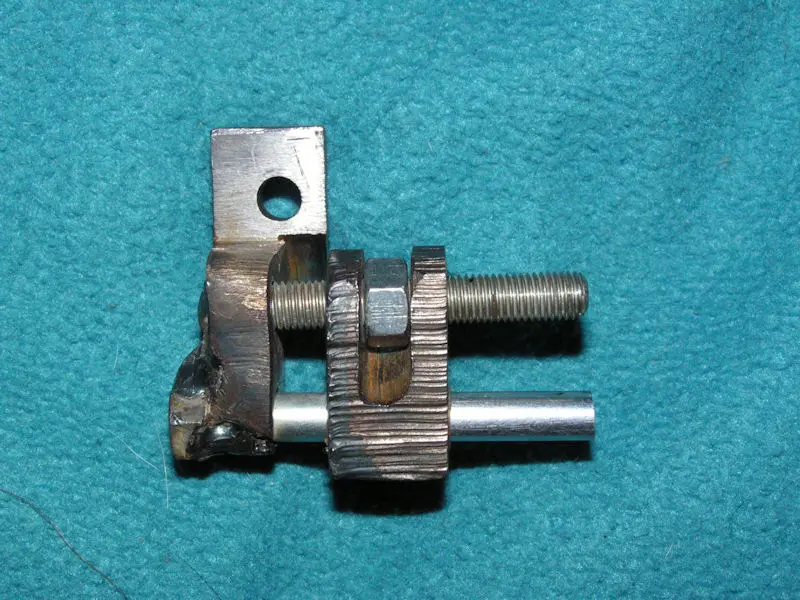

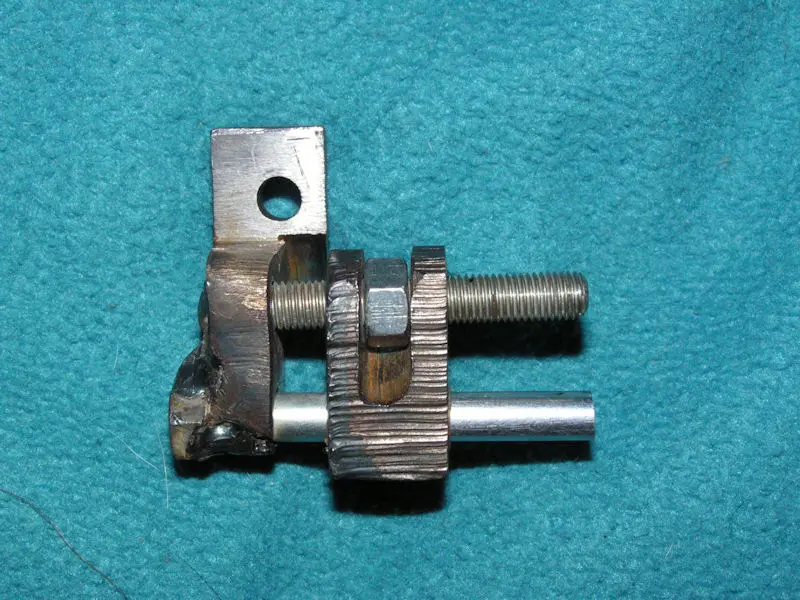

Forward march; Well I never did find the governor setting fixture so I made my own. Worked quite well .

Results 1000 rpm . But When I pulled the cover to check it I discoverd the torque spring was broken.

With the spring gone , is it not possible for the governor to pull the rack far enough to shut the fuel down ? Thanks Tim

Hi Tim,

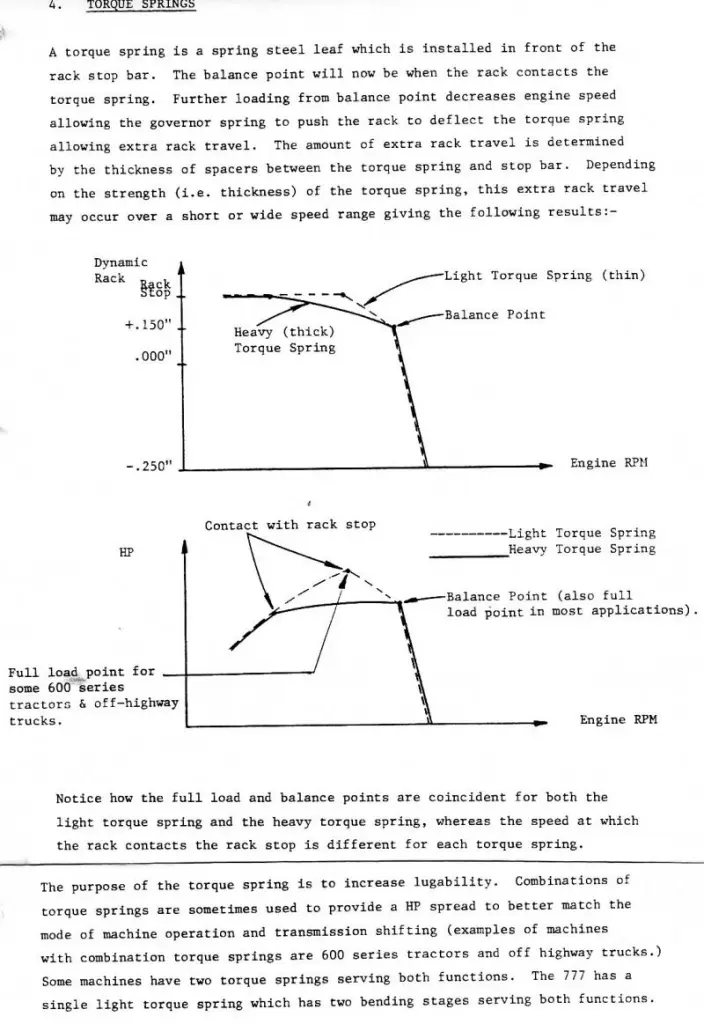

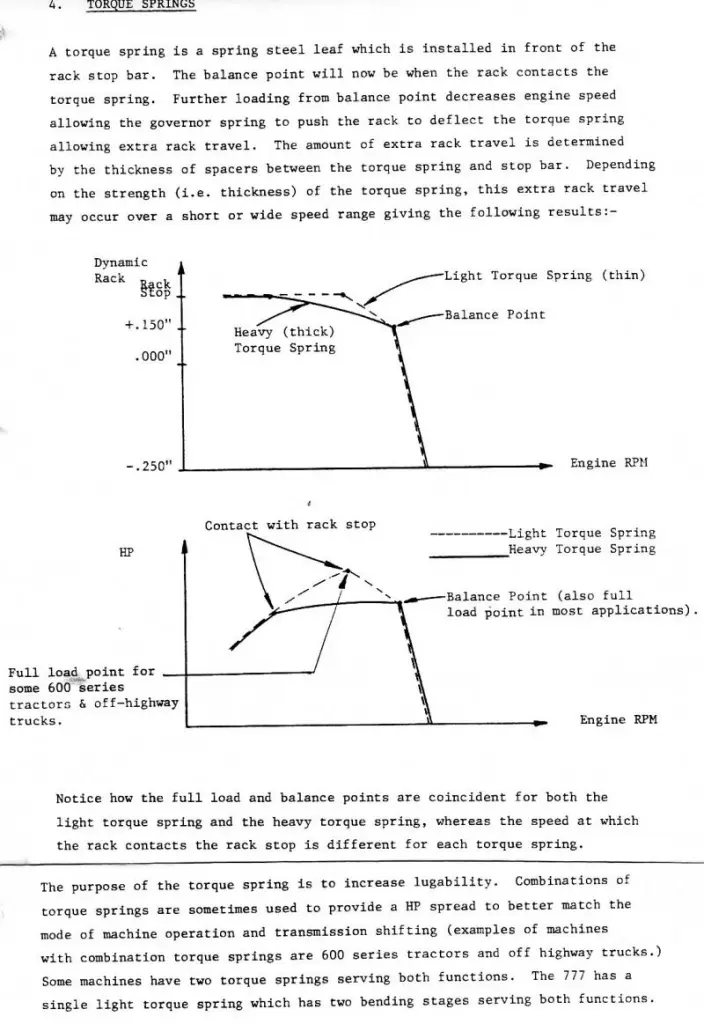

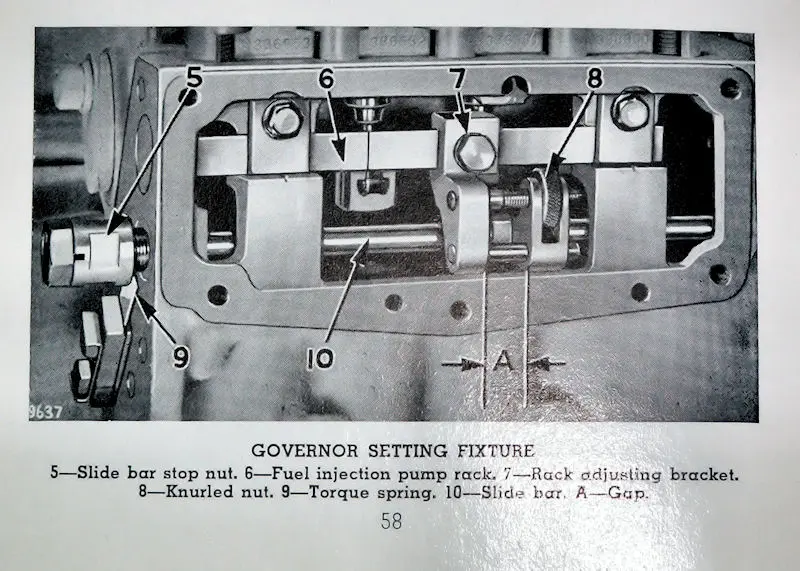

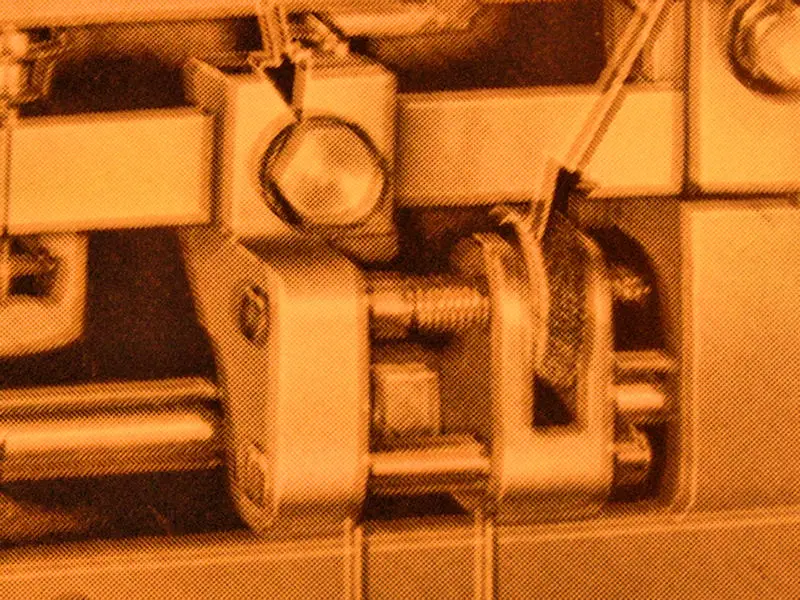

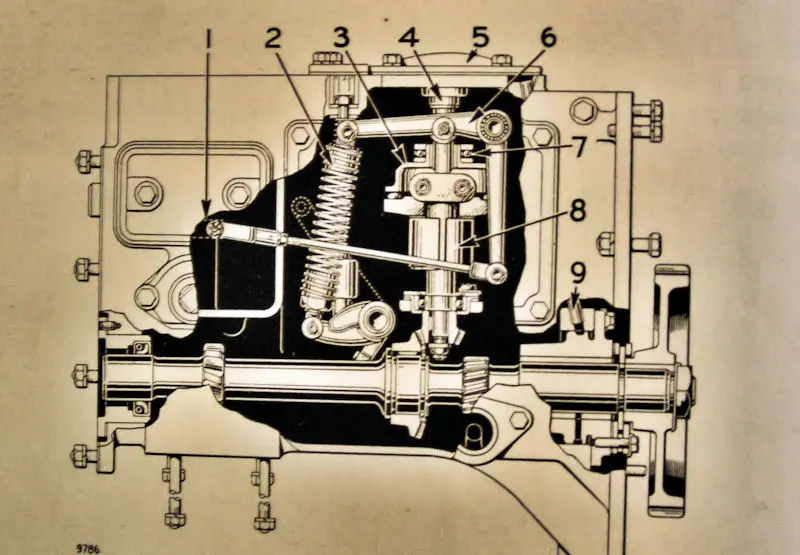

the torque spring function is covered in the scan below.

Your static rack setting dimension is when the rack collar touches the T/Spring but does not deflect it. The torque spring increases the lugability of the engine, as the load increases and the engine speed drops then the gov spring will deflect the torque spring and bring extra rack--fuel--into play to stop the engine dropping further RPM's within the limitations of the engine design.

Normally a stalling engine or almost stalling non-responsive engine would be due to any or a combination of :- sticky rack, flat spots worn onto the Gov. lever/weight- rollers, grouves worn by the above rollers in the Gov thrust race face.

These imperfections cause resistance to the Governors ability to respond to a load change. As a result the engine stalls or nearly so because it does not quickly get the torque spring spacer's worth of extra rack to carry the load.

I guess this is confusing as one usually needs it demonstrated and explained whilst viewing the action of the parts involved.

Hope this helps.

Cheers,

Eddie B.

O"kay; but with no spring in place ,the rack can travel an extra 1/4 inch with no resistance. If the spring were in place, it would not be able to travel thus far in full deflection. Is there more fuel available in the full distance?

At one time or another someone has had their hands on every part of this machine I have found , except for removing some of the corks in the track frame bolt holes.

I cannot shut off the fuel with the hand throttle,if I unpin it and push an extra 2 inches it will shut down.

Trying to adjust low idle has no effect either direction of adjustment . The stop where the plunger makes contact is nowhere within limits of the adjustment.

Might the linkage rod inside be the one to adjust to regain the stop position so the adjustment will function?

In this effort I might recover fuel shut down with the hand throttle no?

All the governor parts look good ,I changed the big spring and have a small spring to change if I need to.

Thanks for your help and replies Tim

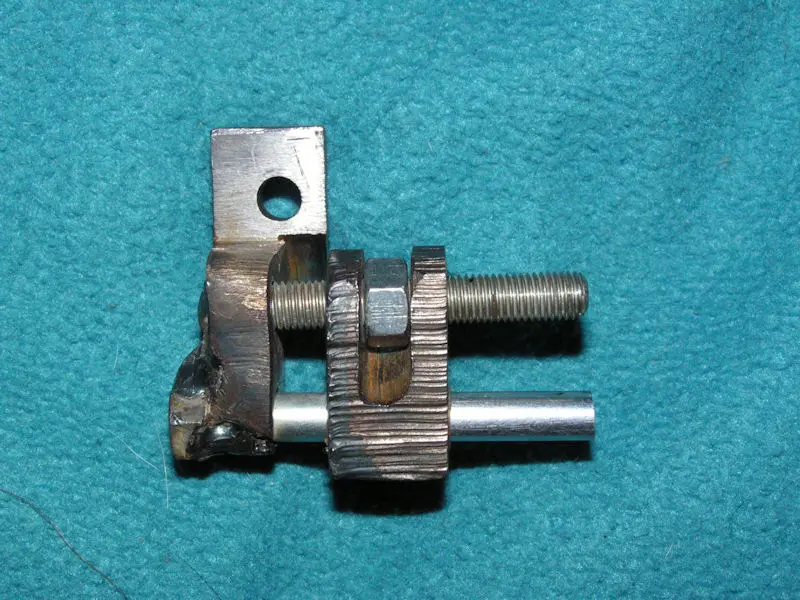

Pictures of my governor set tool.

Hi Tim,

you have done some fancy work to build that tooling, well done.

Silly thought for today is :- I wonder if the injection pump plungers are timed correctly to the rack timing marks.

That is, the plunger segment gears have a machined timing line in the tip of the central tooth that has to match the equivalent mark on the rack bar. If this is not done then the linkage would be out of correct operating range like you are experiencing here.

I am fairly sure that the internal link rod from the gov arm to the rack bar should be fixed at the factory and pinned. some one may have played with it's length or has done so after timing the plungers wrong.

Enough silly thoughts for now, just some things for you to check.

Keep at it, "man will triumph over metal" or as another older mechanic used to say "if man made it, man can fix it" Sometimes we have think outside the square with these things.

Cheers,

Eddie B.

Thankyou for the compliment. Pumps are good ,I installed 4 new ones including adjusting screws. I got thrown off at first, someone installed the flywheel 180 out. So setting them was a bit odd till I figured out what was wrong.

I ordered torque spring today . Tim