Reply to MARCOTEN:

all thanks for the replys,

@gauntjoh: for the pattern i used the old carbtop, i glued it back togetter and put some extra filler on it , specialy on corners to avoid the original squere corners, i made them a bit more round for more strengt and avoiding breakege later, also on the place where the fuel enters i made it a bit thicker for this reason.

i made the entrance of fuel not like original as that was a reson that many tops broke because it used to leak and then by trying to tighten it up to avoid the leaking the tops broke

i cast the extra hub on it for making it possible to put it in a lathe and machine it.

As a mold i used fireproof cement as i didn't have real molding sand.

First i tried several other materials like sand, oily sand, sand with cement, and several others, but that didnt had the good results for me.

the white stuff on the mold is a bit quick plaster as there broke a little piece of when i removed the pattern, and i repaired it.

the first casing in that mold didn't succeed, as there was still too much water in the hardened cement (even i left the mold on the bbq for 1 hour) there became steam/gas bubbles in the casting, so i did it again and it was ok now.

for heating up the aluminium i used my propane oxygen torch, but with a bit more propane then a flame for cutting.

it took me a lot of days to make it, but it was very nice to do and with a nice result!

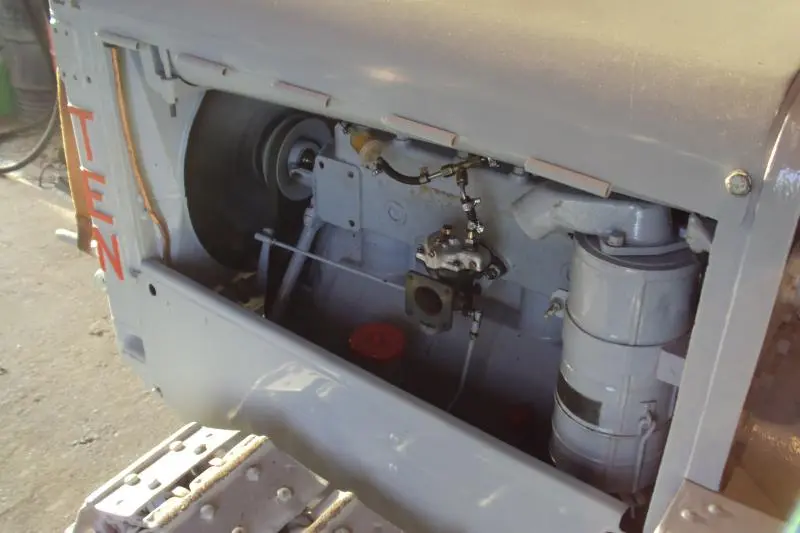

[attachment=15035]DSC01896.jpg[/attachment]

[attachment=15036]DSC01893.jpg[/attachment]

[quote="MARCOTEN"]all thanks for the replys,

@gauntjoh: for the pattern i used the old carbtop, i glued it back togetter and put some extra filler on it , specialy on corners to avoid the original squere corners, i made them a bit more round for more strengt and avoiding breakege later, also on the place where the fuel enters i made it a bit thicker for this reason.

i made the entrance of fuel not like original as that was a reson that many tops broke because it used to leak and then by trying to tighten it up to avoid the leaking the tops broke

i cast the extra hub on it for making it possible to put it in a lathe and machine it.

As a mold i used fireproof cement as i didn't have real molding sand.

First i tried several other materials like sand, oily sand, sand with cement, and several others, but that didnt had the good results for me.

the white stuff on the mold is a bit quick plaster as there broke a little piece of when i removed the pattern, and i repaired it.

the first casing in that mold didn't succeed, as there was still too much water in the hardened cement (even i left the mold on the bbq for 1 hour) there became steam/gas bubbles in the casting, so i did it again and it was ok now.

for heating up the aluminium i used my propane oxygen torch, but with a bit more propane then a flame for cutting.

it took me a lot of days to make it, but it was very nice to do and with a nice result!

[/quote]

Bedankt Marcoten,

Casting with aluminium is something I've often wanted to try, I've just never had a good enough reason to have a go. I think your experience will spur me on to try it out sometime soon.