There is not enough room to remove the water pump without removing the pony on the RD6.

Check the shaft at the packing area, probably grooved and eating up the packing.

Thank you for the reply.

Well darn, that certainly adds a lot of work. I am still interested in the pumps bearing type. Perhaps someone knows or will have pictures to share.

Mine has a Laplant Choate blade lift and the cylinder rods are worn badly in diameter so the seals leak. I may make new rods this summer instead of working on the water pump.

[quote="scooter3"]Thank you for the reply.

Well darn, that certainly adds a lot of work. I am still interested in the pumps bearing type. Perhaps someone knows or will have pictures to share.

Mine has a Laplant Choate blade lift and the cylinder rods are worn badly in diameter so the seals leak. I may make new rods this summer instead of working on the water pump.[/quote]

It’s been awhile, But I am pretty sure that they are bronze bushings,it’s ok to have water pump leaking a little ,lubes the shaft,correct me if I am wrong.

Have you tried fitting more packing behind the nut. Easy enough to do. Undo the nut and wrap as much rope type pump packimg around the shaft so you can still get the nut started on the threads. Please note that the thread is left hand.

Adjust with engine running. As previously stated you are not trying to get a 100% seal. A slow drip is probably ideal.

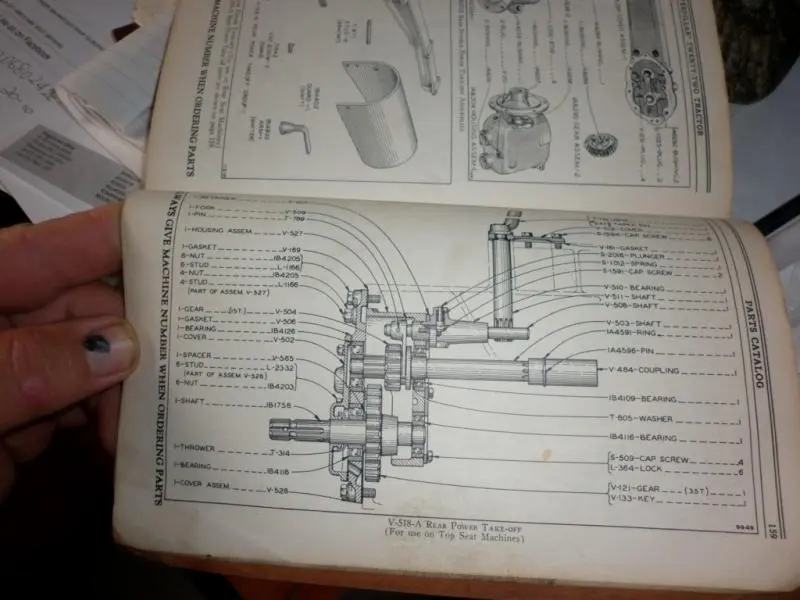

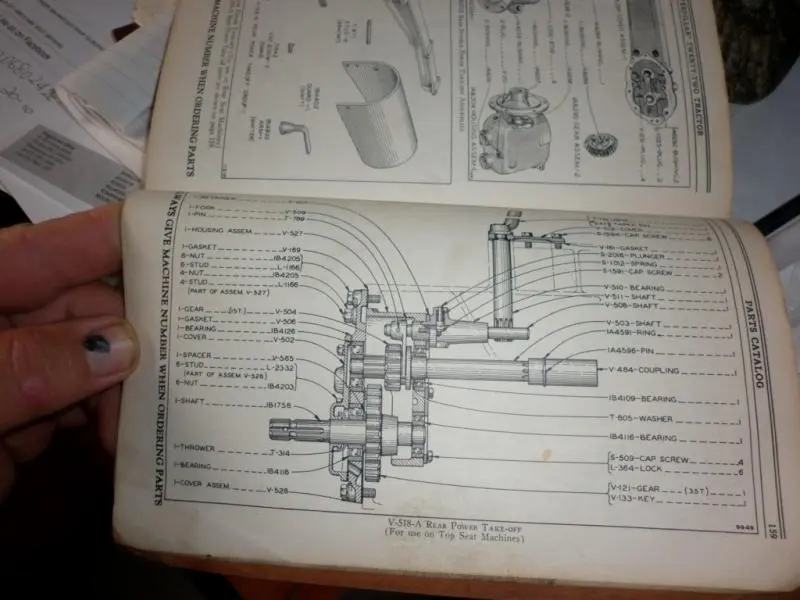

Here are some photo's of the RD6 pump showing the gear drive and impeller end, the impeller has both a keyway and pin, the pilot motor has to be removed but it is not as bad as I thought it would be particularly if you can fabricate a simple lifting bracket as designed by Sasquatch here, my RD6 impeller somehow rotted out both the key and pin so I was forced to remove it.

Mike

Thank you for the replies.

I have repacked it. It leaks a few drips at first and about 20 minutes later it comes out faster than I can use the dozer and have to top off water ever 15 minutes.

I will take the packing out and look at the shaft and see if I can move the shaft side to side to check clearance.

Is there no oil or grease lubricant going to the impeller side? I do not see a grease zerk.

Thank you for the pictures.

Scooter

Thank you for the replies.

I have repacked it. It leaks a few drips at first and about 20 minutes later it comes out faster than I can use the dozer and have to top off water ever 15 minutes.

I will take the packing out and look at the shaft and see if I can move the shaft side to side to check clearance.

Is there no oil or grease lubricant going to the impeller side? I do not see a grease zerk.

Thank you for the pictures.

Scooter

[quote="scooter3"]Thank you for the replies.

I have repacked it. It leaks a few drips at first and about 20 minutes later it comes out faster than I can use the dozer and have to top off water ever 15 minutes.

I will take the packing out and look at the shaft and see if I can move the shaft side to side to check clearance.

Is there no oil or grease lubricant going to the impeller side? I do not see a grease zerk.

Thank you for the pictures.

Scooter[/quote]

No grease zerk but my understanding is the water slowly escaping past the rope seal is supposed to lubricate the shaft, make sure you use graphite impregnated rope when you repack it and use only single layers of rope, it should take 3 or 4 layers of square rope to fill the space under the large packing gland nut.

Mike

Thank you for the replies,

It will be a while before I can get to it, my truck stopped running and some other new problems to fix.

I will get back when I can.

Thank you,

Scooter