Reply to neil:

Yes there are a couple of tricks:

- drill out the soft lead plugs, particularly those on the fuel bowl to gain access to the cross-passages that typically clog on this carb. Use a drill bit in your hand (important!) once the plug is out to drill through the gunk. Once you have them clean (feel free to check with us with photos if you're not sure), use BB pellets to plug the holes back up. Some epoxy them in - I didn't and mine don't leak - clean and round is what you want. Push the bb head in and the tail will also compress nicely to form a seal

- carefully separate the bowl from the throttle body and check that the bullseye gasket is intact. Your kit will have new one but if the old one is chewed out, it can indicate that it is worth skimming the two faces flat with a stone (by hand)

- if the main jet adjusting screw is oriented horizontally, then remove the cover over it and verify that the 90 degree crank that it bears on is actually 90 degrees - it's easy to over tighten and thus bend it

- check that the idle port brass plug is oriented with the notch at the very bottom. Disregard the orientation of the bar on the back of the plug - what's important is that the notch is lowermost - this will give a good idle

- if you need to remove the main jet, make up a good screwdriver that fits very well. They're in there good and it's easy to munch up the top of the jet body

- post pictures!

[quote="Neil"]Yes there are a couple of tricks:

- carefully separate the bowl from the throttle body and check that the bullseye gasket is intact. Your kit will have new one but if the old one is chewed out, it can indicate that it is worth skimming the two faces flat with a stone (by hand)

[/quote]

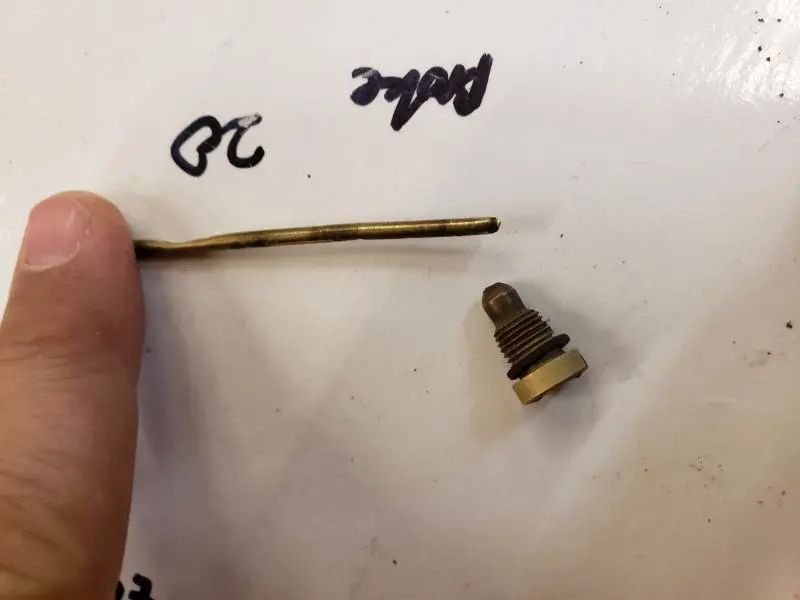

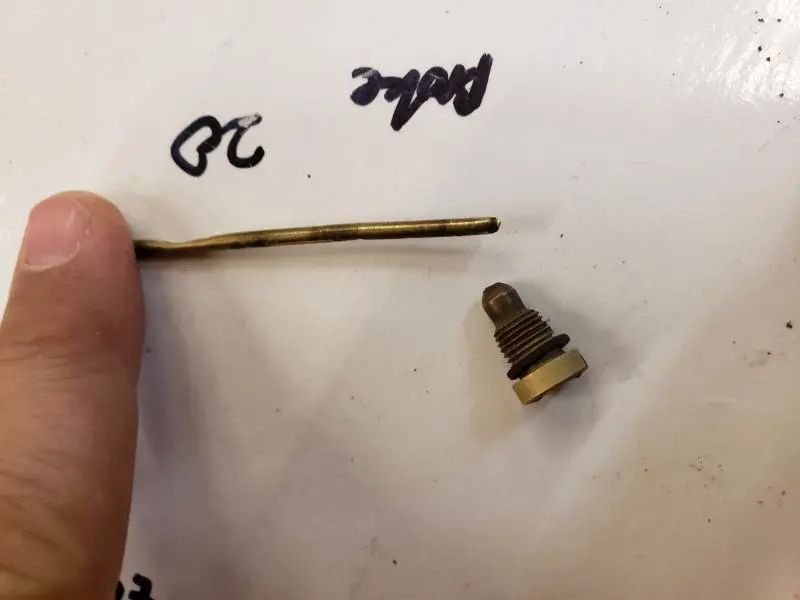

Well another gotcha I'd thought I'd share, since you are more than likely going to remove the fuel bowl assembly from the main carb body to get at the bolt to get the main body off the motor. The idle nozzle screw with a long thin small brass tube goes all the way through the body and into the fuel bowl. So when you separate the fuel bowl from the carb pull straight off, don't try to lever it off. see the end result in picture below

another gem - they don't make the part anymore. Luckily I found someone who had one, but no matter all the prep and searching and forum reading never preps you for the real experience of actually doing it.

[attachment=53506]20190415_120243Editied Arrow.jpg[/attachment]

[attachment=53507]20190414_173729.jpg[/attachment]

[attachment=53504]20190415_114513.jpg[/attachment]

[attachment=53505]20190414_171833.jpg[/attachment]

I hope this posting saves someone, since this post helped me get the courage to take it off as a "junior"