I found this older thread...

www.acmoc.org/bb/archive/index.php/t-659.html

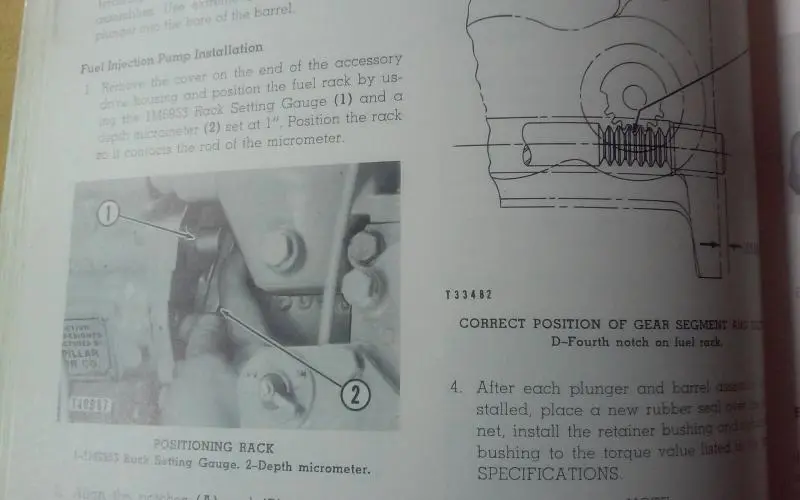

where I was asking about checking the rack setting. The TM says to use the 1M6953 rack setting gauge (appears to be a special bushing) and a depth mic set at 1" to zero the rack before installing a pump into the housing. Eddie B said that the specs he had said to subtract 1" if using the 8M0530 tool instead of the 1M6953 bushing and a depth mic. Does anyone know how the 8M0530 tooling indexes on the pump housing? Does it sit flush on the face or does it fit into the hole there a little?

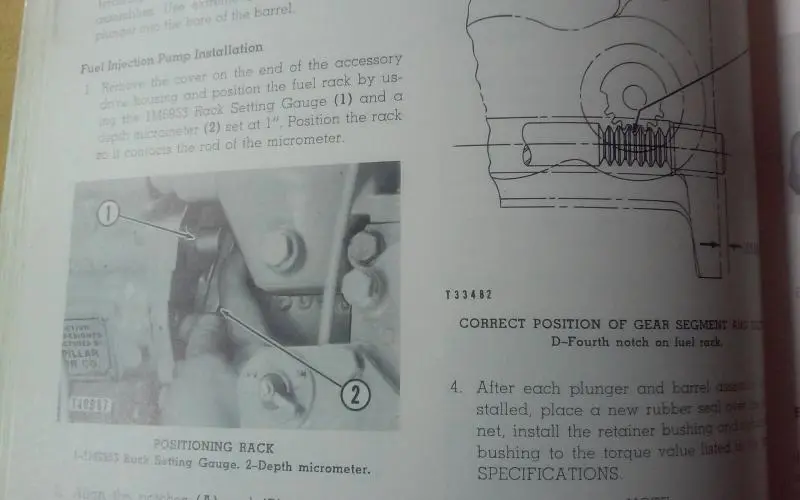

Another diagram shows the center tooth of the pump plunger gear quadrant matching up with the 4th or center notch of the rack. I haven't looked into the housing on the D320, but I assume I can just use that information to get the pumps back in correctly? I don't really have to check the setting, just center the rack to install the pump.

Got the 922b started on diesel today and the rack is stuck, turbo is most likely stuck too because it smokes like a steam engine and the "run away" took a while to build up rpm. Luckily I had planned ahead and had a chunk of mining conveyor rubber belting handy to smother it with. I ran it a few minutes controlling the rpm with the air inlet into the air filter housing but it never started governing. I took the cover off over the end of the rack and it moves slightly but just, so I am going to assume it is stuck.

When I started in on the fuel system i discovered the failed repair of an old crack in the fuel filter housing was preventing priming the fuel system. When I opened the housing to remove the filter before attempting more repairs, there WAS no filter! In addition while the filter housing was off I found quite a bit of sediment and debris in the pump housing fuel gallery. Wonder where that came from? Ha! I cleaned this away and flushed it out but probably just broke some of it loose that is now in the pumps and causing them to stick.

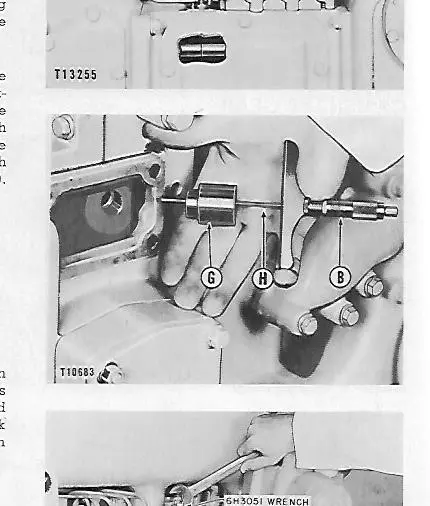

So a disassembly and cleanout is in the cards for this injection pump. I have the 1M6952 wrench or its replacement on the way from Regal corp in Tennessee, so I can remove the hold down rings and I think I can take an old injection line to screw on as an extractor handle to pull and replace them. Hoping for the best!

I appreciate any advice.

D2-5J's, D6-9U's, D318 and D333 power units, 12E-99E grader, 922B & 944A wheel loaders, D330C generator set, DW20 water tanker and a bunch of Jersey cows to take care of in my spare time😄

.webp)