Hi OM,

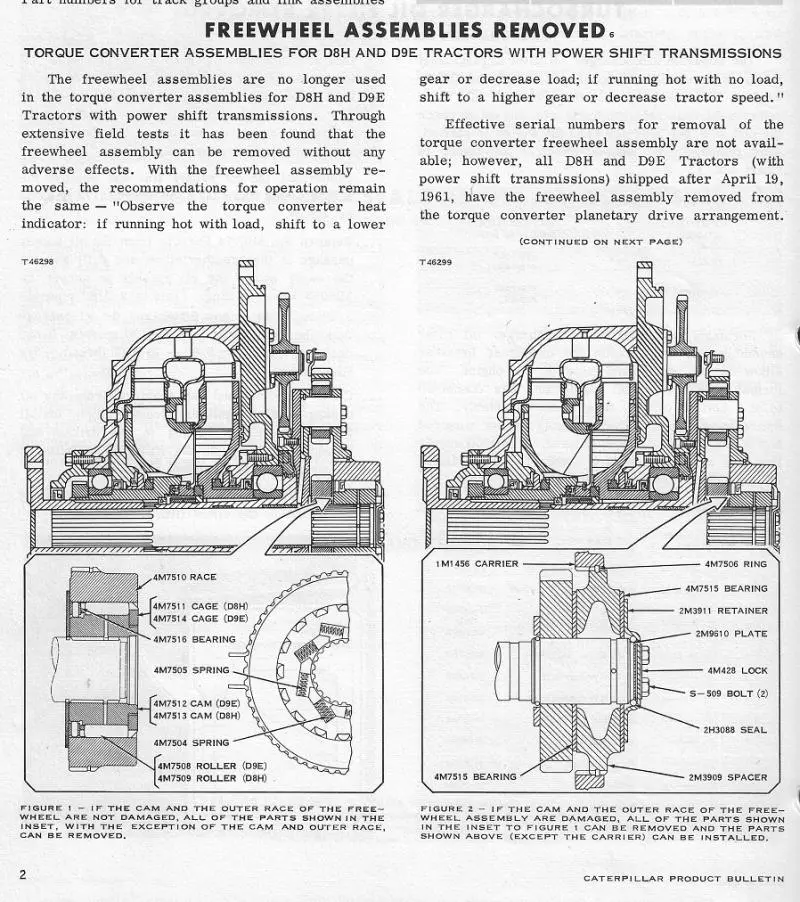

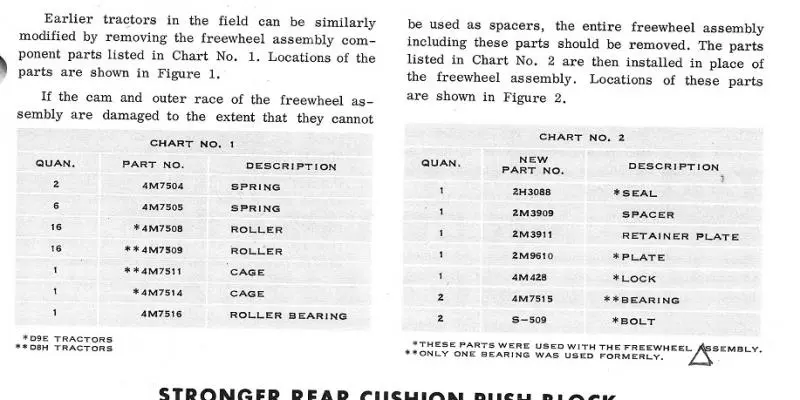

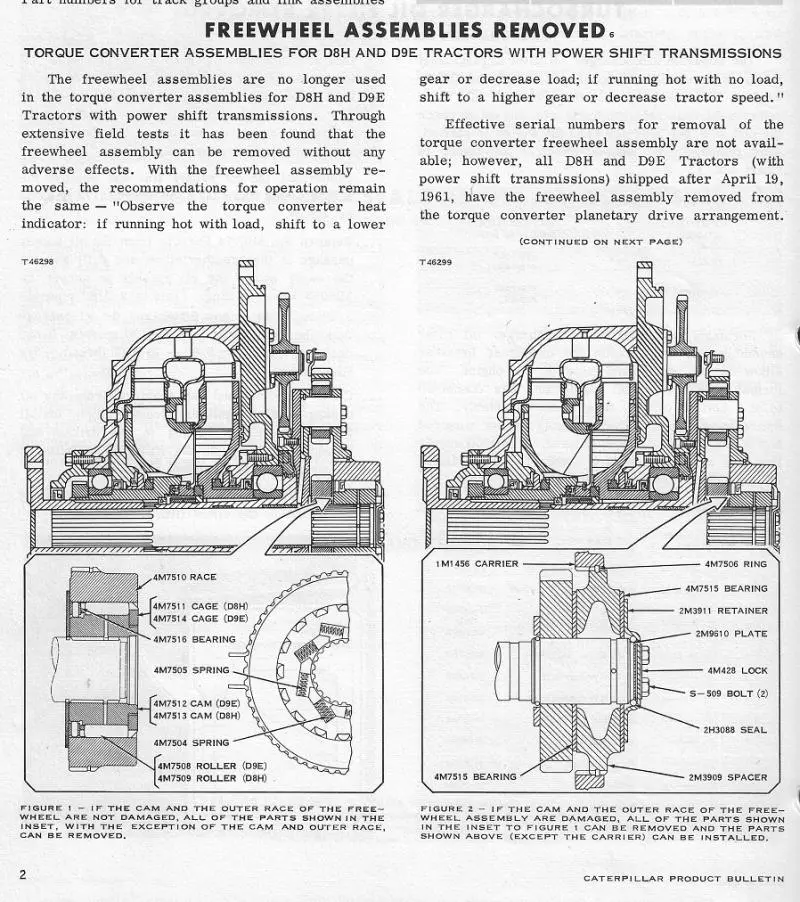

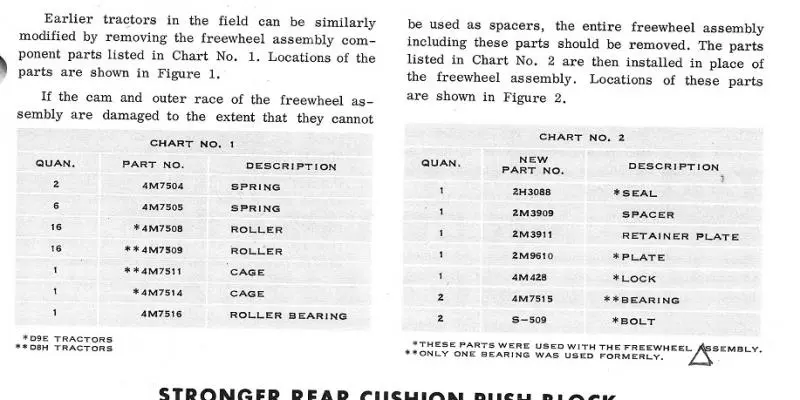

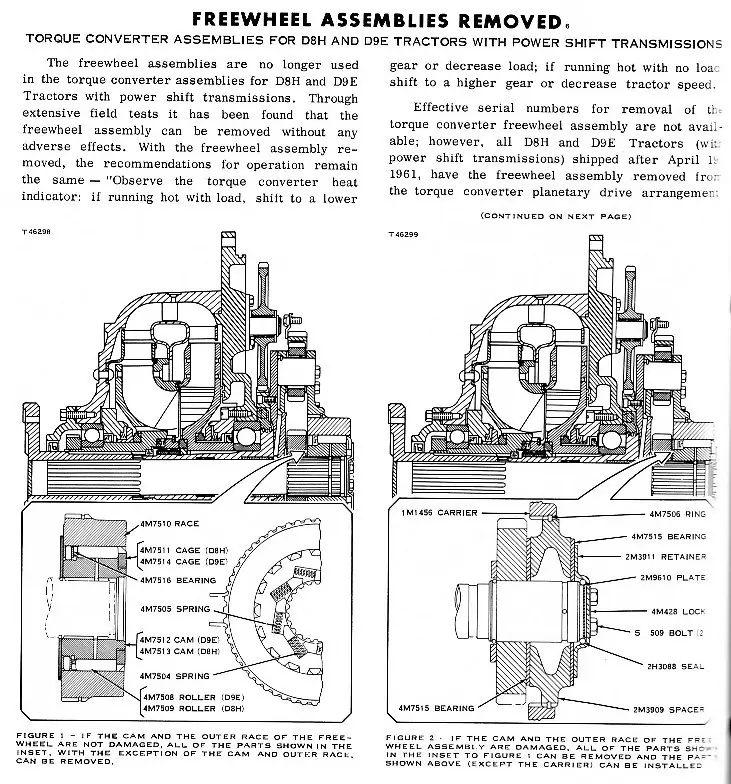

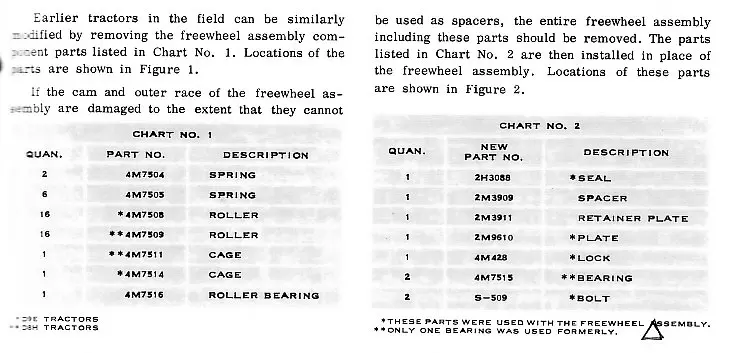

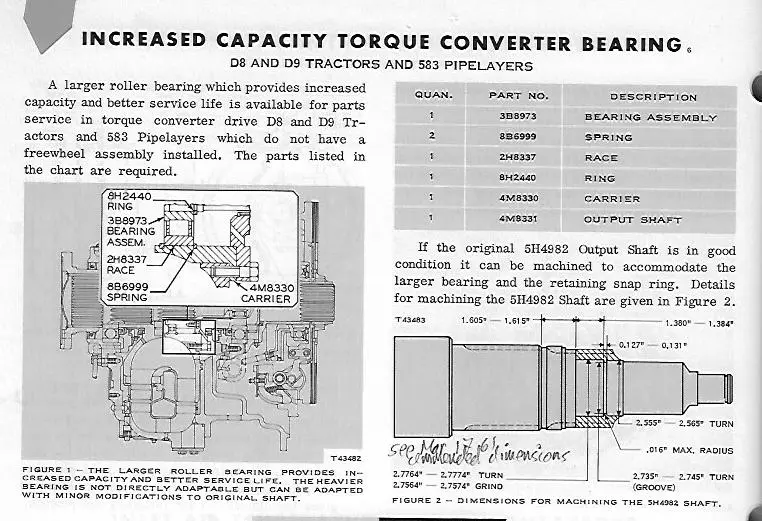

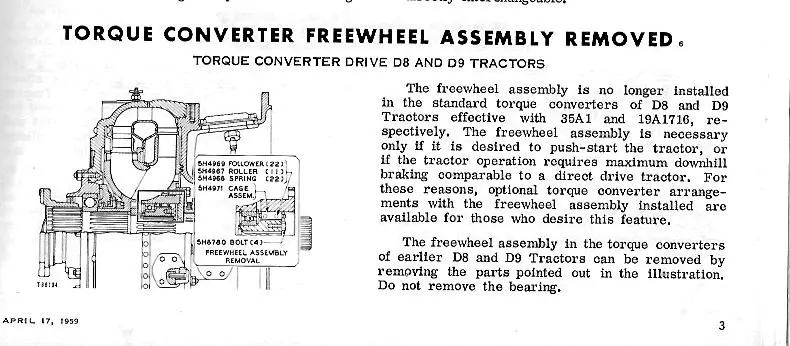

this Product Bulletin -- June 28 1961 -- is all I can find on this subject.

I do recall doing this once and seeing/working on several that had had the Free Wheeling Clutches removed.

My Master Index for Flywheel Clutches and Torque Converters only goes up to 1971 but should show any bearing changes in the 3 Stage units and beyond their production cycle.

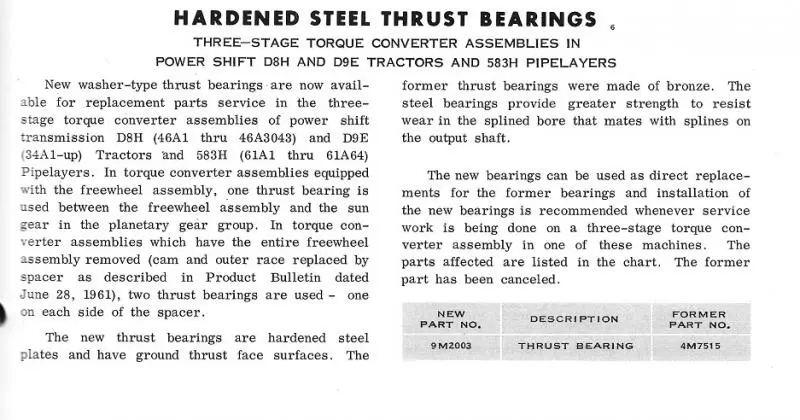

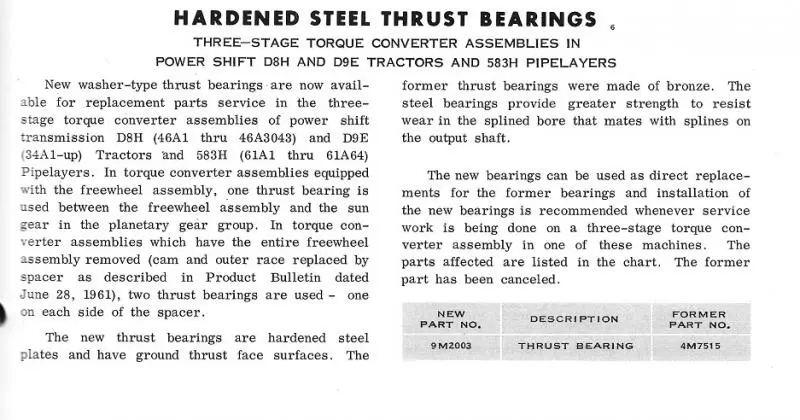

Product Bulletin May 8 1962, tells of Hardened Steel thrust bearings to be used in place of earlier Copper ones.

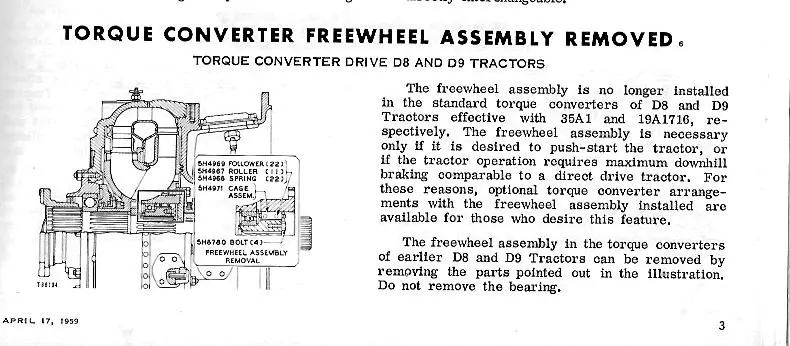

The scans below, albeit for D8H, I believe would also apply to the earlier pre-D8H machines with 3 Stage Fuel Converters--

SORRY if the following waffle confuses things for you but I am simply trying to explain what I recall about the Ball versus Roller bearing usage in the larger early tractor T/C's.

The single stage units were announced in around 1966 for the D8H Powershift units at least from 46A 3044--up.

In my experience I believe the change from Ball bearings to Roller bearings would be for the later Single Stage units, BUT, is likely the difference between the D8H unit as compared with a heavier D9G unit--I stand to be corrected.

There are certainly both types that I have worked on and it may also be that with subsequent HP increases to the D8H that they upgraded the D8H/K units to incorporate the heavier duty Roller type bearings to take the thrust of the Impeller.--Serial Number checks in Parts Books may show at what S.No's this may have occurred at--if at all.

My literature does not go late enough to cover any possible upgrade from ball to roller bearings in the 3 Stage Fuel Units as is what you specifically asked about--may have to check NPR for any possibility of a conversion being possible to an early Ball bearing supported unit.

As an aside at a Cat School on Powershift Transmissions in 1965 we were told that there was a huge safety factor of transmittable power thru the later single stage units--something like 30 times.

Many years later I was testing a D8K with a sticky rack that was opened way up by someone falling for the sticky rack coming up short on true maximum rack setting dimension.

I am sure that the T/C cavitated!!! when Cat Engineers were questioned on this they said "No Way that can happen"

--I was the one testing it and the engine Rpm's definitely rose along with a strange rumbling sound coming from the T/C--????

Keep asking if you need more data or if I have confused you with the extraneous waffle.

Cheers,

Eddie B.