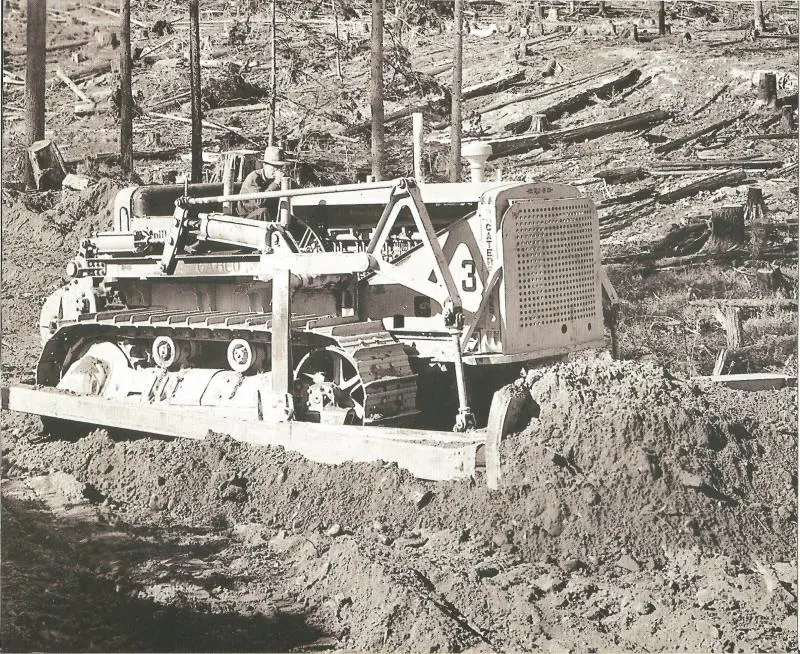

Can't tell for sure, but I'd suspect that setup is because they're both single acting cylinder, hence you need one for lift and one to push the blade down. Single acting is easier because you don't need to have a gland that holds pressure, just piston seals. Or it could just be a way to get more force without going to a larger cylinder, but I'd think just going to a slightly larger cylinder would be easier than adding a 2nd complete cylinder.

I believe the manufacturer is "CARCO" of winch fame. Push arms actually attach to rear draw bar. No trunnions.

You have a wonderful day. Best wishes. Deas Plant.

Hi, Johan7.

It would be worth bearing in mind too that this would have been a low-pressure, high volume system, as were almost all hydraulics of that era. With the low pressure and the reduced piston surface area of the rod side of the piston, they did not have a lot of power on the 'In' stroke, hence the cylinder 'pushing ' for the blade lift.

Just my 0.02.

Looks like he was cleaning up a logging job! That's my cup of tea!

Whats really interesting is that the cylinders to push down are also smaller and of less mechanical advantage as the cylinders tht lift the blade. Makes sense as there is blade weight to help go down and more lift is required to lift and push as when grubbing stumps. Over all I find it a very interesting setup. It would be cool if there is still one around somewhere.

You have a wonderful day. Best wishes. Deas Plant.