Reply to 1stDeuce:

Were the pony engines still running like that? The Cat 12 grader we bought has a noticeable "clunk" in the pony as you crank on it with the starter, but no noticeable rattle once it's running. Then again, once it's running, everything is clattering and rattling, so who's to say...

I'm guess I'm wondering if we also don't have some wasted rod bearings... I am not excited to pull it all apart, that's for sure... The oil we drained out smelled very faintly of gas, and there was no way to shut off the flow of gas to the carb as we bought it. There is now a shutoff inline, and some fresh 15w40. I hope to hook up the shutoff in the cab at some point.

Thanks for the pics!!

Chris

[quote="1stDeuce"]Were the pony engines still running like that? The Cat 12 grader we bought has a noticeable "clunk" in the pony as you crank on it with the starter, but no noticeable rattle once it's running. Then again, once it's running, everything is clattering and rattling, so who's to say...

I'm guess I'm wondering if we also don't have some wasted rod bearings... I am not excited to pull it all apart, that's for sure... The oil we drained out smelled very faintly of gas, and there was no way to shut off the flow of gas to the carb as we bought it. There is now a shutoff inline, and some fresh 15w40. I hope to hook up the shutoff in the cab at some point.

Thanks for the pics!!

Chris[/quote]

squanch253 YouTube channel dose some great explanation on videos of the D2's and RD6's pinion clutches and pony engines. The pony engine blocks used by the D2 and D4 models were similar from 1932 to early 1960 - late 1960 through 1964 Pony engines were classified as NOS.

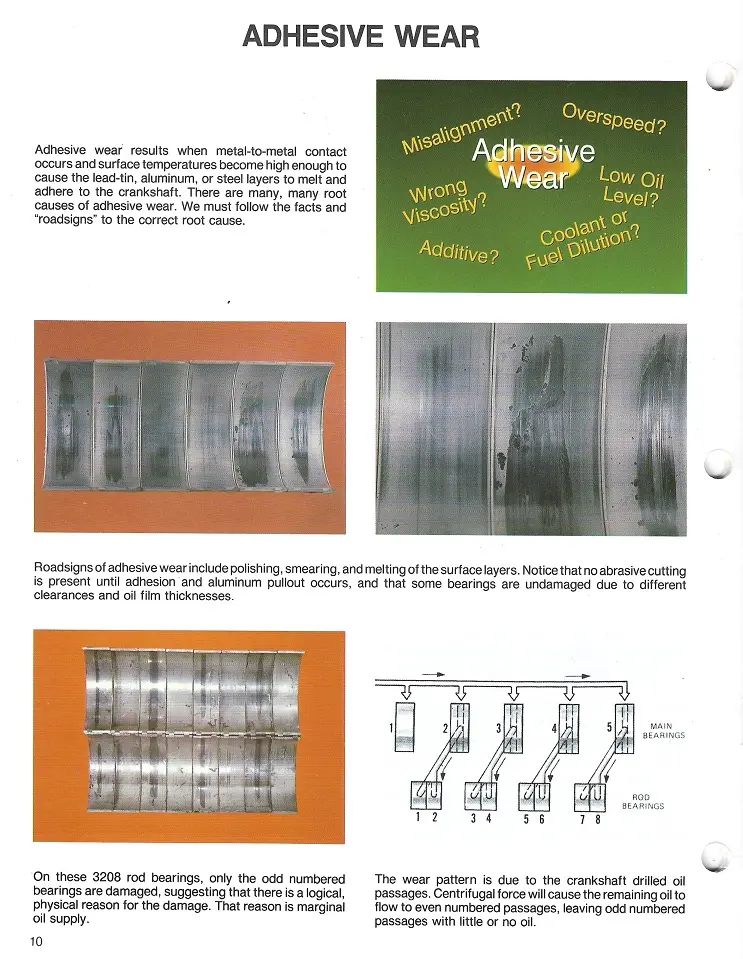

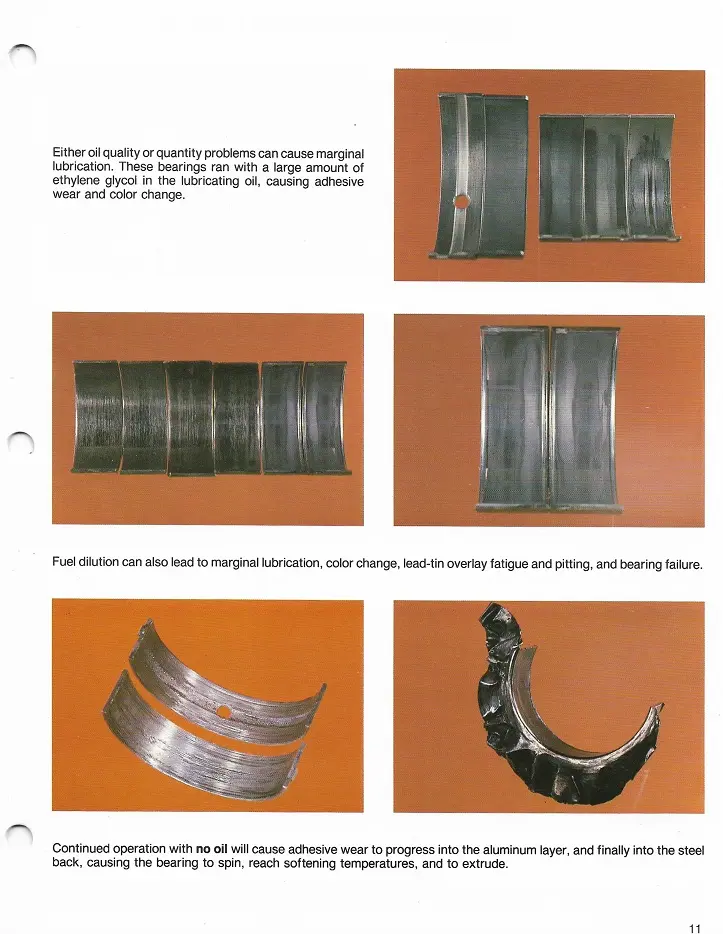

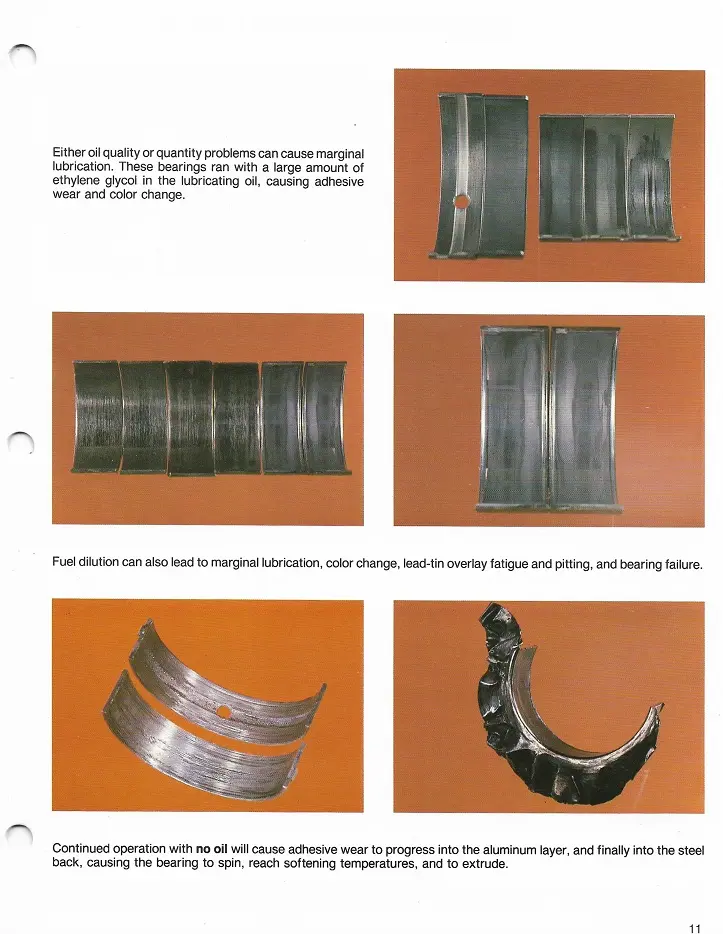

The same line of reasoning can be applied to the bigger pony engines used by the larger Cat RD and D models. These old pony engines are tough as nails, pun intended, they are bulletproof all the way until they are not; then the inside become outsides. THEE biggest problem with the pony engines is the operators bad practices and habits on starting, running and shutting down the pony. Let me explain, the starting engines were only designed for about 250 hours of service and they only hold about a quirt of oil; because of the tremendous amount of vibration the old rigs produced, the downdraft carburetors allow any gas in the float bowl to pass the seat and enter into the crankcase. By shutting down the pony using the Mag switch creates a scenario whereby after each start the oil gets flushed out, thinned, more and more to the point it looses its lubricating properties. This lack of lubrication causes hot spots on the rod and main bearings which can be seen happening in the pictures. So it is imperative to let the pony run out of gas and die, using up all the gas in the carburetor.

The main bearings are another chapter in themselves; the pins that hold the main bearings need as much help as can be provided by technologically - red bearing lock and the like. These small pinned bearing set the crank end play and basically hold the engines together. A spun main bearing means there is a metal pin and shavings in the oil and they are not long for the world. Large amounts of end play or redial play is indicative of a spun main bearing. Spun main bearings cause a common crack in the block where the bearing is pinned in the block.

After starting the pony, I've seen most people get excited to start the diesel engine and totally forget the reason for having a pony to begin with - guilty as charged. Not allowing the pony to worm up is a bad practice because it causes undue wear to the engine. Starting any cold engine and immediately putting it to maximum output creates stresses between differing expanding metals that can cause catastrophic breakdowns without having any prior problems. Simply allowing the pony engine to quickly come to operating temperature not only reduces stresses on the pony engine but also gives the larger diesel engine a chance to bring up lube and fuel pressures and warm the intake air on later models. In extreme cold weather I would suggest putting a percolating block heater on the pony and if you can find one a magnetic oil heater (VW shop) - a dipstick heater will work but remove before starting due to the substantial crank pressure can blow out the oil and heated dipstick.

From what I have read on the forms about the type of oil used in these old rigs should only be straight 30W; detergents in the multi-grade oils flush the old encrusted sediments loosening them up to revisit moving parts. In extreme cold the use of 10W is imperative. Side note: while working on the North Slop I saw a service oilier cut the ends off a can of 30W at -20*F and he pushed the oil out of the can from one end and held the oil in his hand like a thick rubbery jello.

If you haven't done it by now I strongly suggest go watch squanch253's videos on pony teardown and rebuild.