You have a wonderful day. Best wishes. Deas Plant.

Hi, Case on a Cat.

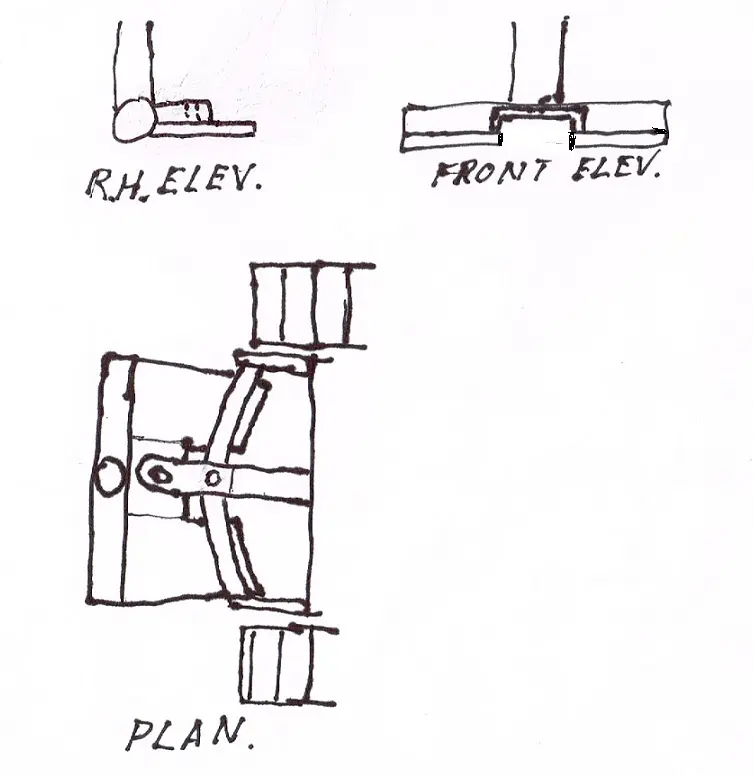

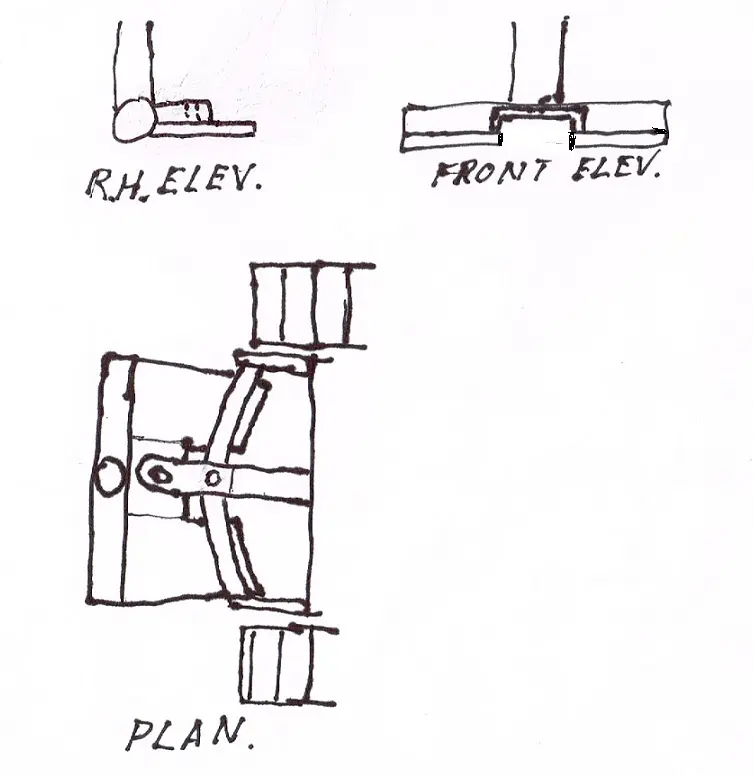

UNLESS I miss my guess, that 'goofy home-made hitch' was made by someone who had a pretty fair understanding of what he was doing to attach to a 3-point linkage system on a wheel tractor WITHOUT needing the top link of the 3-pt hitch. It already has the pivot points for all 3 planes of movement built into it, horizontal and vertical pivot and tilt. I think you could do a WHOLE LOT worse than sticking with what you have there and modifying it to fit your D2 drawbar. See the attached 'black-n-white' print for some idea of the way I am thinking.

[attachment=39756]Scraper Hitch_1.jpg[/attachment] (This sketch work comes from the same fine art MS Paint facility as the previous lot in an earlier post. LOL.)

Azfer drawbar height, set the scraper on the ground behind the D2 withe present drawbar horizontal beam set on blocks at the same height as your D2 drawbar clevis, hook up the hydraulic lines and go through the full range of stroke to see what you currently have and what you need to do to make it work.

The advantage of keeping the current hitch and modifying it is that the unit would be easier to reverse into anywhere than if you use dolly wheels and a drawbar tongue.

Just my 0.02.

Carl,

Nice little pan for your D2.

IMHO, you could go two ways for sure. The more complicated hitch would be to start with two arms from a 3 point hitch (tractor bone yeard) then tie them together with a double plate and lead out from the center (like a sandwich) with a say 8 inch plate with a hole for your drawbar pin to go through. You would then have two places to accommodate the forward pitching of the D2 as it moves.

The easier way would be to take a similar plate with some gussets and weld that to the approximately 4 inch pipe directly under the vertical pin and let the slop in the drawbar pin and holes take care of the pitching of the tractor. Lots of ways to go here and you will find a way. As Deas suggests, it would be a good idea to position both together and operate the hydraulics to give you an idea of how much movement you have to work with.

Get 'er done so it can go with the rest of the load to SM!

Jan

Nice little scraper there I am looking for something similar but maybe just a tad bigger Jason

I think I would hook that thing to a wheel tractor and understand how it operates before I start cutting and modifying.

Most of the Overland and Eversman scrapers used the two lower links of the three point hitch to raise and lower the blade as well as pull it. The hydraulic cylinder operated the dump mechanism.

At least this is how the little scrapers like that I have operated or the neighbors had.

I think I would hook that thing to a wheel tractor and understand how it operates before I start cutting and modifying.

Most of the Overland and Eversman scrapers used the two lower links of the three point hitch to raise and lower the blade as well as pull it. The hydraulic cylinder operated the dump mechanism.

At least this is how the little scrapers like that I have operated or the neighbors had.

I agree with CR most of those little scrapers use the three point lift to raise and lower the cutting edge! Using the one remote circuit to dump the bowl

I think I would hook that thing to a wheel tractor and understand how it operates before I start cutting and modifying.

Most of the Overland and Eversman scrapers used the two lower links of the three point hitch to raise and lower the blade as well as pull it. The hydraulic cylinder operated the dump mechanism.

At least this is how the little scrapers like that I have operated or the neighbors had.

Found this on YouTube of a similar style scraper

https://m.youtube.com/watch?v=r9y9TZfvPBQ

You have a wonderful day. Best wishes. Deas Plant.