I have no direct experience with your lgp d6 but I did run a d3b lgp. I ran a d6d and wouldn't consider a d6 a swamp machine. If you're going to be using it as a general purpose dozer I would cut them down. The problem comes when you get in uneven terrain which can put a lot of pressure on the outside edge of the track pads. Stumps and rocks and such is where the increased wear comes in. I will say the d3 lgp machine was a dream to run but was just used for finish work and pushing swamp type dirt

yes that's what i was meaning Gary, general purpose dozer, just stump jumping

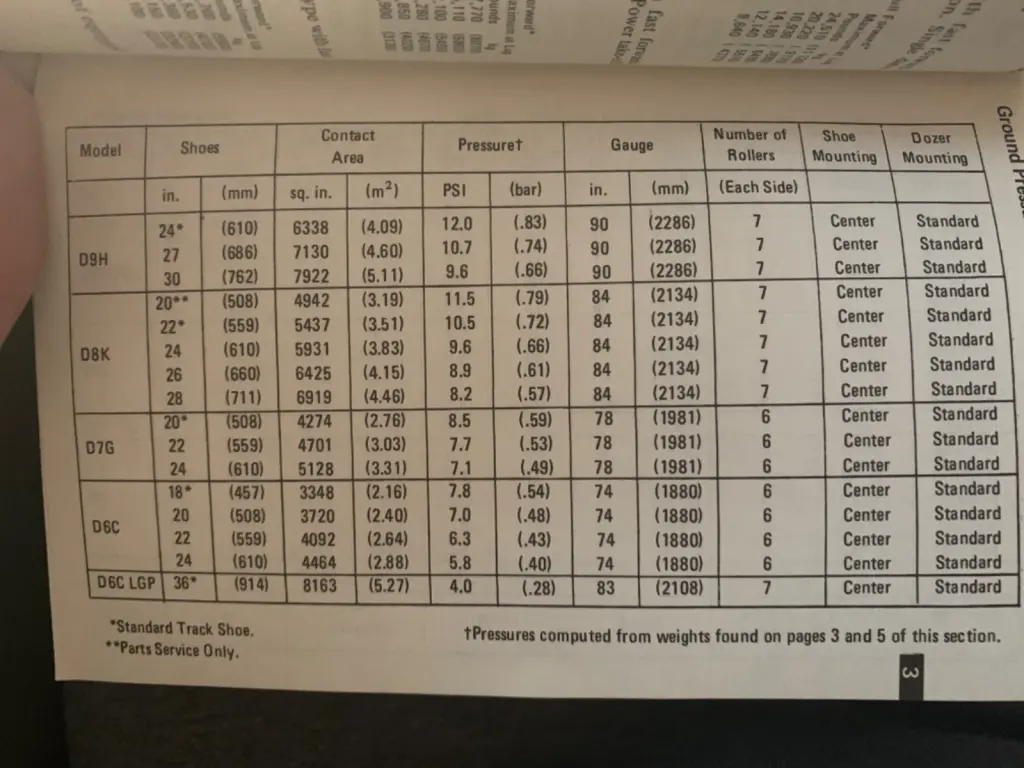

The standard track shoe for the D6C or D6D LGP is 36". The 30" pads were intended to reduce wear when flotation was not needed as much. The extra wear to the undercarriage from operating in dry conditions is caused not only by the width of the track pads but also buy the extra length of the roller frames/tracks.

Trimming the pads is a bigger project than you think, unless the undercarriage in really great condition I don't know if any gain you would achieve would be worth the effort of the trim job.

The easy fix is to adjust your operating procedure to avoid sharp turns and rough terrain until it's time to replace tracks.

The wider pads are nice for snow. You might regret the trim in winter.

Craig

D46U straight blade,D46U cat angle blade,allis chalmers AD4 grader and Khoering 404 dragline. D4C 40A,D4 2T and scraper.

isn't the grouser bar height on the lgp pads lower than standard pads? if you trim it might affect traction???

not sure how i would get 36" shoes to fit and clear everything, it's already tight confines..

-yes it's a big job for how much benefit, that's the dilemma...is it really worth the time and trouble...?

Okay, I thought you were talking about 30" pads on a D6C LGP machine, 30" pads on a standard D6C would be maxed-out.

Still a tough call as to weather the potential gain is worth the effort.

Craig

and what would be the most cost/time efficient way to cut shoes?

-oxy-acetylene

-big plasma cutter

-mechanical band saw of some kind

-other?