[quote="Glum"]A little while back there was some discussion on power tilt cylinders fitted to manual angle blades. Here are some pics of my conversion. Sorry about the quality from the crappy cellphone camera.

I managed to find another sectional valve bank the same as is fitted to the D4E so I was able to add another section without having to do any cobbling up. The cylinders came off of some old Komatsu D41As. Had to cut down the rod slightly and change the clevis. Modified the blade lift lever to work on two axes.

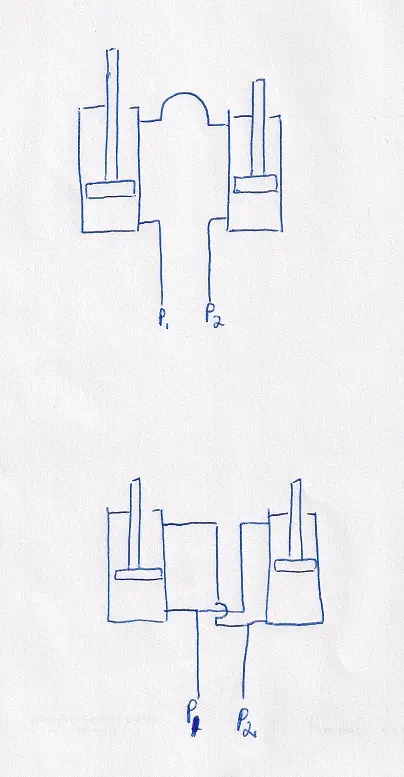

I opted to go with two cylinders and have plumbed them in series so that they have to move at the same speed rather than a parallel arrangement where the oil tends to want to work the cylinder with the least resistance first.

I'll be putting it back to work tomorrow to see how it works in the ground.[/quote]

So you have them hooked up like a re-phasing cylinder with out the internal by-pass?

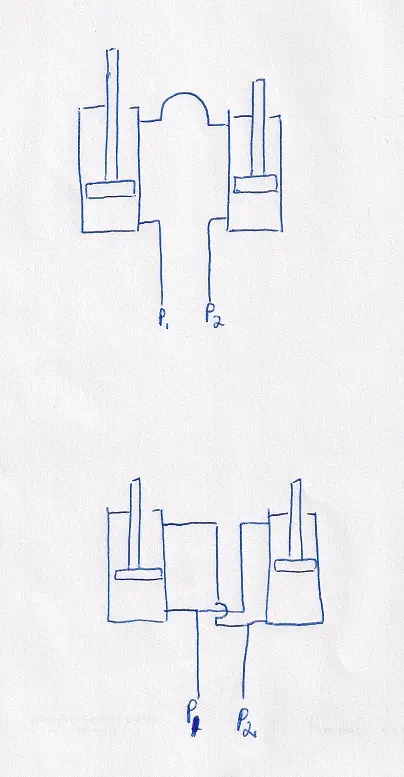

By plumbing them in series does the oil flow into one cylinder to extend and then exits it on to the other cylinder to retract it? do the cylinders have different ram areas for extend and retract?

I see what your asking Dpendzic, they will want to travel at different speeds given the same flow and pressure. I'm gonna bet they will work against each other to some extent but still work, I could be wrong though.

It looks nice to me Glum, I may try something similar on my D7E someday.

OK I'm thinking better now, I guess he has the rod ports hooked together, that way they both have the same area so as to retract/extend the same but in opposite directions.

I'm thinking like Joe that there maybe some volume/pressure differences as the rear of the piston has more area than the front where you would subtract out the rod diameter.

Stephen has it. Plumbed like the top diagram.

The angle cylinders on some of the older cat pat blades I have looked at are plumbed the same way.

Was a bit tricky purging the air and getting oil into the rod ends as they are a separate reservoir from the main system unless there is leakage on the pistons.

The oil displaced from the rod end of the first cylinder has to enter the rod end of the second cylinder, forcing it to move at the same speed as the first.

My reasoning was not that I need the force of two cylinders, just to create enough movement to give enough tilt without destroying the centre pivot after some use.

In effect, they actually operate as single acting cylinders! Force pushes them back verses Pressure pushing them back! The oil would assist the Force. A lot of the older Snowplows would have single action cylinders for left and right angle. In the case of tilt, you would need the oil in front to buffer the forces generated by the cutting edge. Nice Job! Well thought out!

Hi Glum, how did you get the oil into the rod end circuit? I'm guessing you have a port at the high point of the line and used a funnel?

Also I meant to ask the group what the term is for leaning the whole blade back and forward - I'm familiar with angle and tilt but don't know what that third movement is termed?