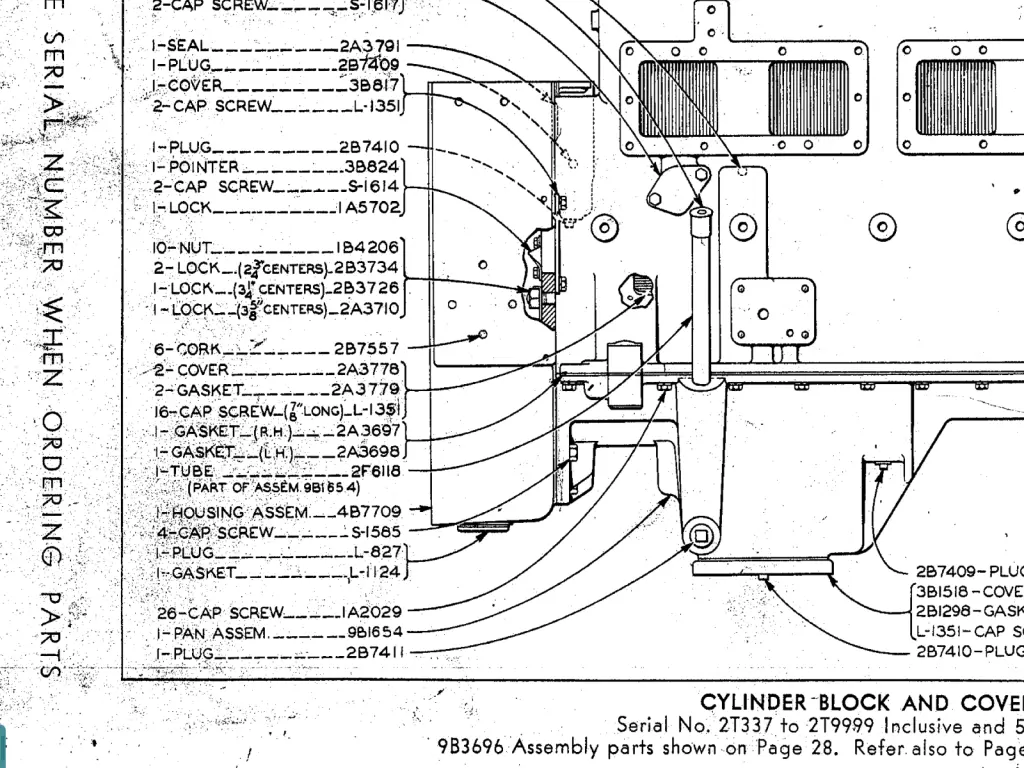

Check the "NOTE" at the top of the parts diagram. It states which part number cap screws have lock washers.

Hi Team,

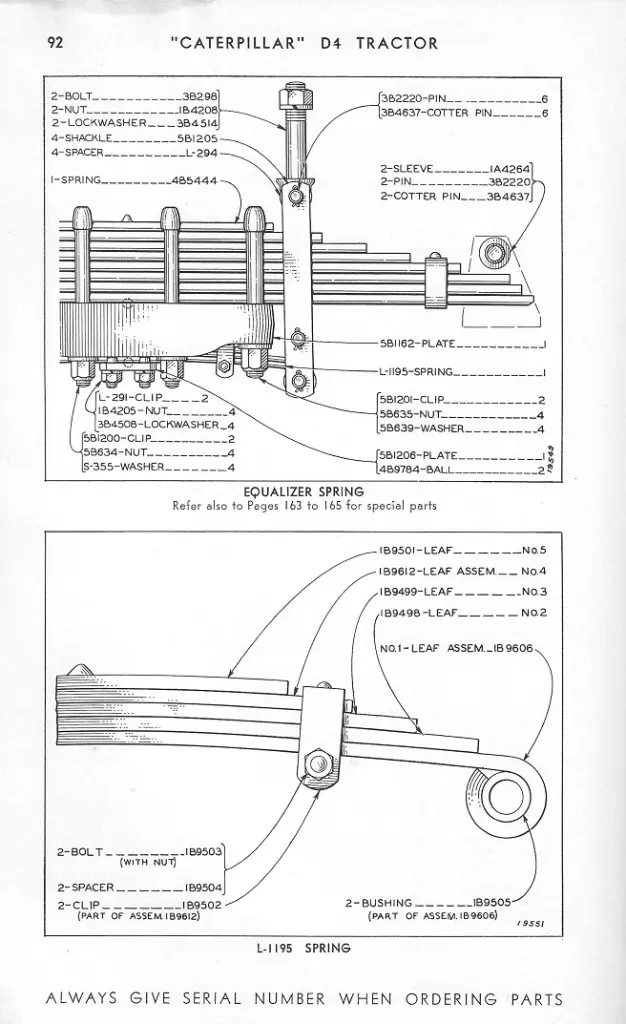

would also suggest you check for excessive wear at the track frame ends of the spring and the brackets on each track frame that position the spring--excessive wear here and at the track frame outer pivot bearings can cause the spring to rub against the sump pan spring seat for and aft faces.

It maybe that these faces are excessively worn allowing the spring to contact the bolt heads in operation.

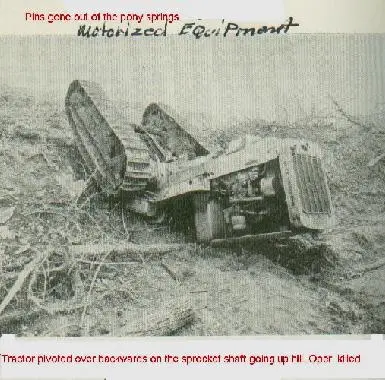

The jockey/auxiliary spring, links and system also help maintain equalizer spring location--operating without the auxiliary spring system can lead to a fatal outcome as they and the bolts/pin and sleeves on the track frame spring seat brackets stop the front of the tractor rearing up and over onto the operator as shown in the scan below.

Cheers,

Eddie B.

Excellent info, Eddie, as usual! Thank you. I'll check that. The spring has been wearing against the sump of oil pan as there's an area with no paint in one corner so there's definitely movement due to wear. I'll try and hunt down some spring wear info and compare and contrast.. I do know of someone with spare spring so that might be the ultimate answer! Always learning..

Regards,

Tony

Now I'm a bit nervous after edb's post and the flipped over dozer. I remember seeing pictures of similar fatal tragedies with D2's flipping over. What should I look for in my D2 to make sure there is not enough wear to cause this? If the ends of the leaf spring are inside their mounts on the track frame, is that ok? How much wear or telltale signs should I look for?