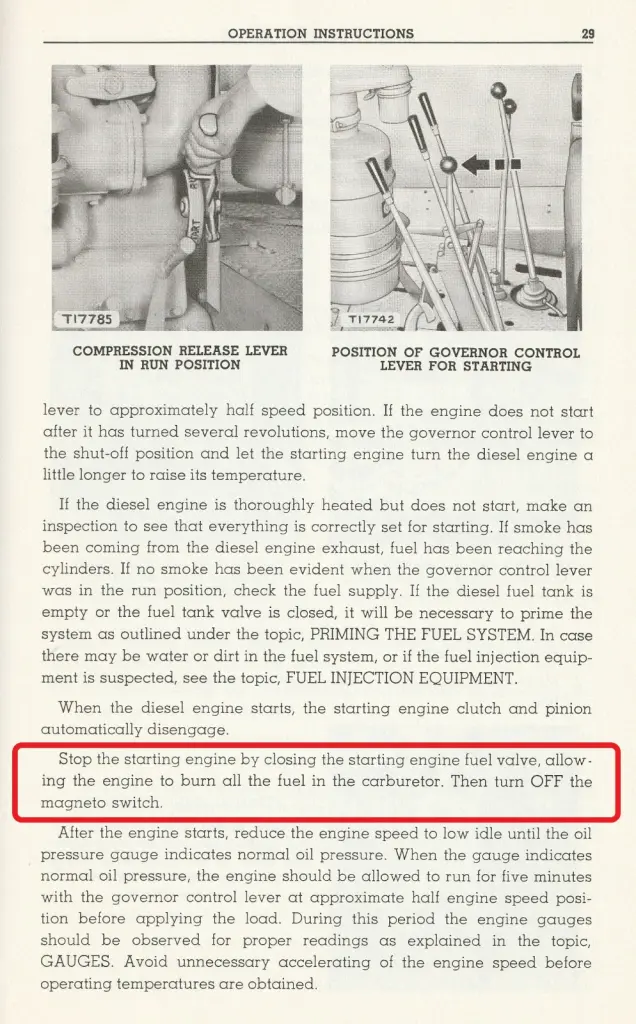

It's difficult for me to determine the reason for your trouble by your description. I do know you should ALWAYS shut the pony off by closing the fuel valve.

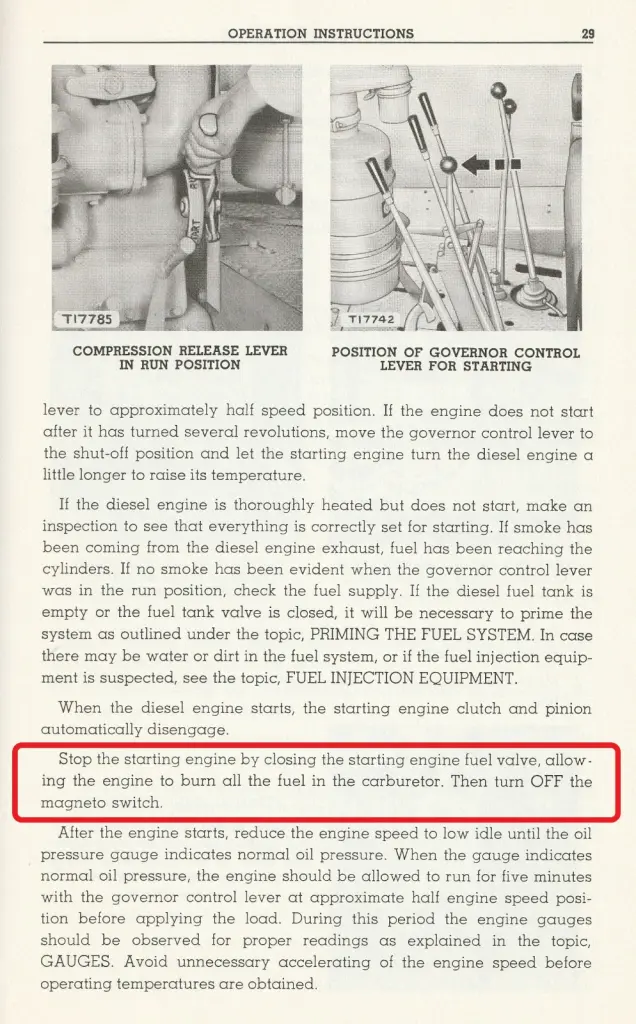

The Operation and Maintenance Instructions(OMI) contains much useful info. There is a copy in the ACMOC library + more 17A info but you need to be a paying member to access them. I have included a page of the OMI.

Craig

I found these on eBay depending on your S/N:

https://www.ebay.com/itm/205037316587

https://www.ebay.com/itm/195852051068

[attachment=77936]IMG_20240105_0009.jpg[/attachment]

Couple of thoughts

- inability to tune using the mixture screws sometimes indicates air leaks. I know you said you've checked but I'd be inclined to perform a controlled leak check by sealing up the carb in various ways and doing a vacuum test using a hand pump. One source of leaks that's sometimes overlooked is the throttle and choke shafts (more so the former

- also can be due to incorrect fuel bowl level

- overfull crankcase. This happened on my buddy's HT4 - it would not start at all until I removed the oil fill cap, and then it started right up. It was overfull and was causing excessive pressure "bucking" preventing the carb from functioning correctly. It was overfull due to the float valve not shutting off, but any over-full state will have the same end result. We drained the contaminated oil, refilled to the correct level, replaced the fill cap, and confirmed that it would start right up again.

Check the level as well as confirming that the dipstick is the correct one for that engine. If you can post the approximate level in the crankcase referring to, say the bottom surface up to the oil level, someone on here can tell you if that sounds right, as a way of verifying that your dipstick is correct

- some other condition preventing mixture reaching the cylinders - check by putting a small amount of fuel directly in the cylinder, replacing the plug and checking if it will fire. I've seen rags jammed in the intake manifold and in the exhaust manifold preventing running

- spark plugs that will spark in the open air but not under compression -

Couple of thoughts

- inability to tune using the mixture screws sometimes indicates air leaks. I know you said you've checked but I'd be inclined to perform a controlled leak check by sealing up the carb in various ways and doing a vacuum test using a hand pump. One source of leaks that's sometimes overlooked is the throttle and choke shafts (more so the former

- also can be due to incorrect fuel bowl level

- overfull crankcase. This happened on my buddy's HT4 - it would not start at all until I removed the oil fill cap, and then it started right up. It was overfull and was causing excessive pressure "bucking" preventing the carb from functioning correctly. It was overfull due to the float valve not shutting off, but any over-full state will have the same end result. We drained the contaminated oil, refilled to the correct level, replaced the fill cap, and confirmed that it would start right up again.

Check the level as well as confirming that the dipstick is the correct one for that engine. If you can post the approximate level in the crankcase referring to, say the bottom surface up to the oil level, someone on here can tell you if that sounds right, as a way of verifying that your dipstick is correct

- some other condition preventing mixture reaching the cylinders - check by putting a small amount of fuel directly in the cylinder, replacing the plug and checking if it will fire. I've seen rags jammed in the intake manifold and in the exhaust manifold preventing running

- spark plugs that will spark in the open air but not under compression -

I think you might have a combination of problems. Spark plugs that have been repeatedly soaked with raw gasoline are suspect even if they look okay. If the tractor has been operated after the pony has been improperly shut off with the mag switch the pony oil is diluted with gas and should be changed.

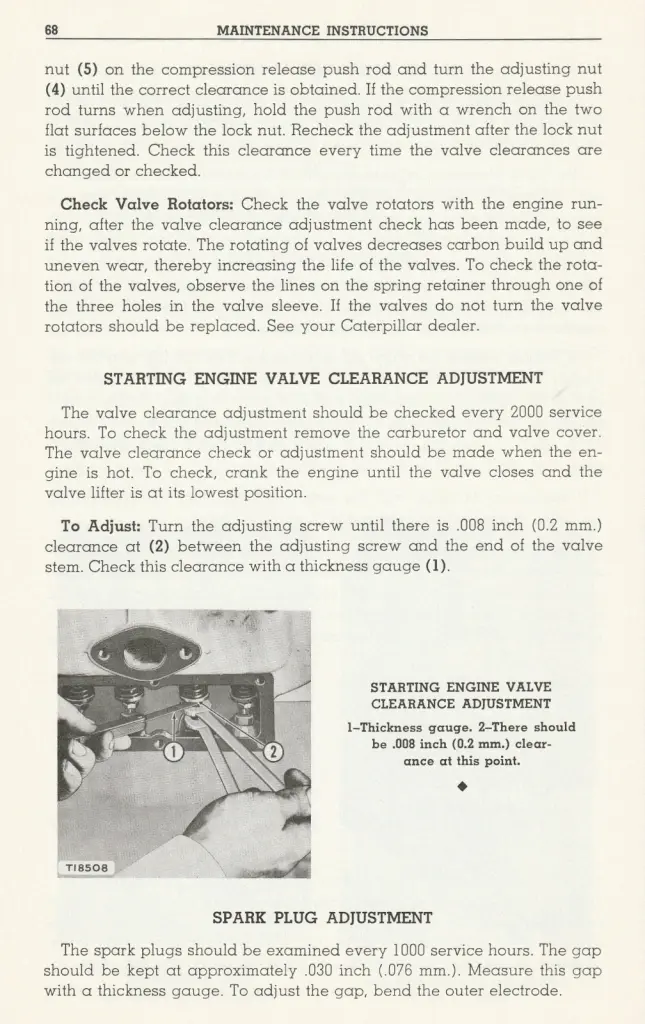

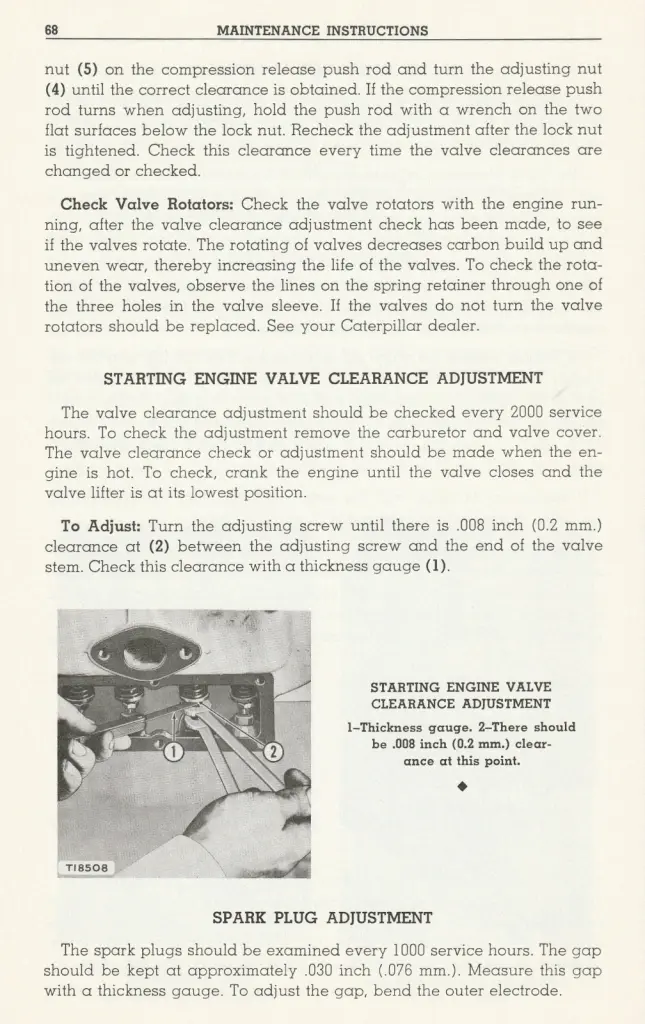

I took a look at the D7C/D (17As) Service Manual in the ACMOC library and spotted several things.

How long has it been since you checked the pony valve clearance? The valves may not be opening fully and contributing to or compounding the problem. here is another OMI page.

Craig

[attachment=77937]IMG_20240105_0048.jpg[/attachment]

I did the valve clearances a while ago and it has not run for more than a few minutes since. I’ll check them again though. I changed the oil recently too and it smelled like petrol

I would try and find another good magneto, and swap it in to try, it is possible the coil in yours is breaking down. Even if you see sparks jumping with plugs sitting outside the engine when you are cranking it, those same plugs will often not be working when put under compression, or heat.

If you've sprayed ether in and it didn't fire, then ignition is a problem (perhaps not the only problem but any amount of spark, no matter how weak, should ignite a charge of ether and air. Do it a few times - remove the carb entirely, spray a shot of ether in the intake and try starting it - if it doesn't even fire, then you have an ignition problem if your compressions are halfway decent

This is the magneto here, does anyone think there might be a reason why someone has soldered the wire onto the condenser? I’m going to give this whole thing a clean at least

"i reject your reality and substitute my own" - adam savage. i suspect my final words maybe "well shit, that didnt work"

instead of perfection some times we just have to accept practicality