The simplest and most effective fix for your situation is to disengage the pinion. This is done by removing a small cover on the clutch/flywheel housing on the left side, near the left brake pedal and over the pinion. You will see the pinion latching mechanism there with 2 latches, each with an adjustment screw secured by a cotter pin. If you pry or bump the end of either of the latchs with the adjustment screw, the pinion will release and move toward the seat.

The fact that the pony is turning the main engine even with the pinion clutch disengaged means your pinion clutch is dragging. The pinion clutch doesn't need to be adjusted very tightly. Unlike the main transmission clutch, it requires only a weak "snap" to go over center as you move it forward after engaging the pinion into the flywheel. Even with it adjusted loosely, sometimes it is quite hard to brake the pinion as you prepare to engage it into the flywheel. This results in grinding and damage to pinion and flywheel ring gear teeth. Draining that pinion compartment and flushing with kerosene or diesel fuel and then refilling with engine oil or ATF can help dramatically. There is also a procedure to modify the pinion clutch disks so they do not have so much "stick-tion" from the oil between the steel and brass disks if you cannot get good results from the flush and refill. Mine really worked well after refilling with ATF instead of motor oil. The lubricant in that compartment is vital since it travels up to the pony crankshaft and camshaft gears which get no lubrication from the pony motor oil supply.

Ron,

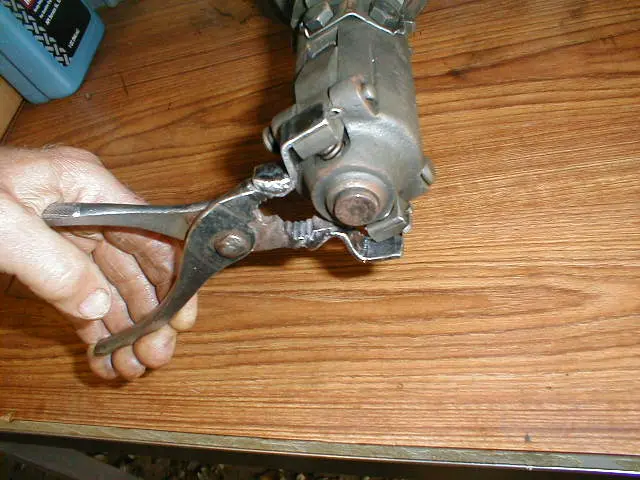

The two pinion latches are interconnected by a sort of gearing so that when one is pushed, the other should move as well. I suppose this could be damaged so that both latches must be moved simultaneously or more likely the pinion is just stuck. I remember some pictures of a tool made to reach in the access cover and squeeze both latches at the same time that someone posted several years ago. It was made on a vise-grip of some type with long jaws.

Have you sprayed it with penetrating oil etc? Some spray and repeatedly cycling the pinion engage lever to move it even slightly may work it loose. If worse comes to worst, you may need to remove the pinon assembly after you lift the pony off.

Are you considering converting to direct electric start?

Coleman, another solution to your problem is to pull or push start the D2. The diesel will spin the pinion and disengage the latches after it starts or possibly before if you pull it fast enough.

Thanks for the input guys. I will try pulling the machine to see if it can be freed up that way.

After that I will also do the flush and fill as suggested. I learned not to engage that pinion when not needed. Too late but a lesson I won't forget! I love these old cats but have very little knowledge to work with. This would have never happened had I known better. I feel like a kid that broke his favorite toy.......lol.

Here are some pics of the tool ccjersey referred to...

[attachment=23986]2163.jpg[/attachment][attachment=23987]2164.jpg[/attachment][attachment=23988]2165.jpg[/attachment]

does anyone see any problem with enlarging that access hole much larger to get working room?? Mainly for tightening the latches up a little.

does anyone see any problem with enlarging that access hole much larger to get working room?? Mainly for tightening the latches up a little.

Well today I flushed out that clutch assembly and refilled with ATF. Turning the pony engine is a bit easier than when I first started working on it but it does feel as if there must be some clutch drag still.

When I looked at the dozer before buying it the owner started the pony first pull and it was ice cold and probably hadn't been started in a couple of months. I started to wonder if it got some crap in the carb from the long ride home so I emptied the gas tank out and it looked good. I also pulled the carb apart and cleaned it. The engine has plenty of spark and now all I can figure is there is enough drag on the engine that it can't quite get going when I pull it over.

Maybe tomorrow I will get someone to give me a hand to see If I can get the main started by pushing it with the Skidsteer. After that maybe it will free things up? I have sort of run out of ideas or options as far as I know. What next?

Does anyone know if running the main might help free things up a bit? Once again thank you for your help!

Did you check to make sure the pinion clutch lever is not also in the "engaged" position, which would keep the pinion clutch applied and not allow the clutch plates to slip when the pony is firing? That's about the only other thing I can think of to check outside of what has already been mentioned. But being that you were able to engage the pinion easily yourself, I would doubt that it would now be somehow stuck in its current position. Sometimes they require a bit of force to disengage the latches, espescially if they're set up properly.

Your situation reminds me of something that I had happen last year - last September I had my 5U D2 at a local tractor show, parked with the rest of the old Cats in the line. On the second day of the show I began the starting procedure a little bit before the parade was scheduled to start and noticed right away that the pony seemed a little finicky on initial startup. It has always started right up and ran well, but this time it stumbled a bit at first and I had to quickly put the choke on a bit then open it again to bring it to a steady idle. I remember thinking how that seemed odd because it had never done that before, but I just attributed it to the old joke about how even the most well behaved pony motors will only ever act up in front of a crowd of spectators.:censored: But as I applied the pinion clutch brake, then pulled up on the engagement lever I noticed that something really didn't feel right! Turns out that somebody had apparently been fiddling around with the levers earlier in the day and had managed to engage the pinion, which is what made my pony act a little funny at startup. I just kind of shook my head a little, and had to smile to myself thinking of how somebody probably was just pulling levers to see what they would do, and maybe even got startled a bit when the one on the side suddenly seemed to stop doing anything after they had pulled it all the way up.:eek2::jaw: But lucky for me, the drag in my pinion clutch wasn't sufficient enough to keep the pony from starting so I was still able to make the parade.😖mile: